Aug . 12, 2024 10:02 Back to list

Innovative Solutions for Bulk Mesh Production in Wholesale Markets and Manufacturing Industries

Understanding Wholesale Mesh Manufacturing An Overview

Wholesale mesh manufacturing plays a pivotal role in various industries, serving as a fundamental component for a plethora of applications, from construction to agriculture, and even fashion. Mesh materials come in a variety of shapes, sizes, and materials, offering versatility and functionality that meet the diverse needs of consumers and businesses alike.

The Diversity of Mesh Products

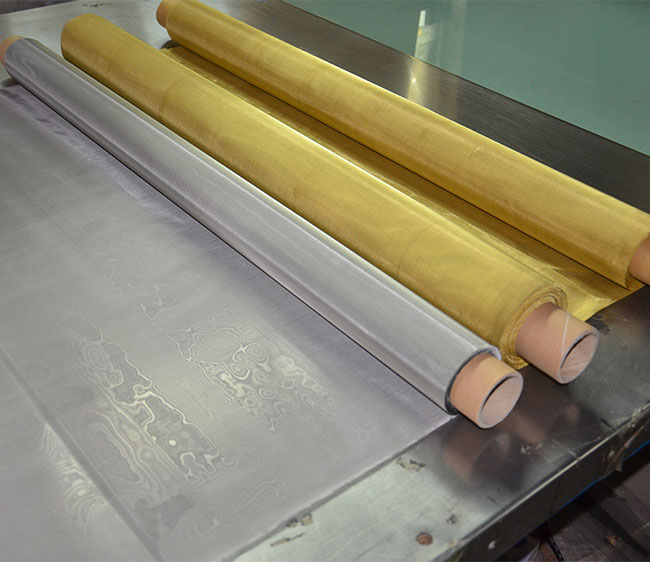

In wholesale mesh manufacturing, the product range is vast. Mesh can be made from metals, plastics, or natural fibers, providing options for different environmental and performance requirements. For example, metal mesh is often used in architectural designs or as security screens due to its strength and durability. On the other hand, synthetic mesh is favored in agricultural applications for its lightweight nature and resistance to rot and corrosion.

The manufacturing process itself varies depending on the type of mesh being produced. Techniques like weaving, knitting, and extrusion are commonly used, each imparting unique characteristics to the final product. For instance, woven mesh is typically stronger and more rigid, making it suitable for heavy-duty applications, while knitted mesh tends to be more flexible and breathable, ideal for items like clothing or automotive interiors.

The Importance of Quality Control

In the wholesale mesh manufacturing industry, ensuring high-quality products is paramount. Quality control measures are implemented at various stages of production to maintain consistency and reliability. From selecting raw materials to the final inspection of finished products, each step is crucial in determining the durability and functionality of the mesh.

Manufacturers often adhere to specific standards and certifications to guarantee that their products meet international safety and performance criteria. This is particularly important in industries like construction and healthcare, where subpar materials can lead to significant safety hazards or regulatory non-compliance.

wholesale mesh manufacturing

Economic Benefits of Wholesale Mesh Manufacturing

Wholesale mesh manufacturing not only serves functional purposes but also contributes significantly to the economy. By providing bulk products, manufacturers can lower costs for businesses that require large quantities. The economies of scale achieved through wholesale production allow manufacturers to offer competitive pricing, which is especially beneficial for small businesses.

Moreover, the industry generates employment opportunities, from skilled labor in manufacturing to roles in sales, logistics, and customer service. This economic impact extends beyond the factory floor, as suppliers, distributors, and retailers also prosper from the demand for mesh products.

Sustainable Practices in Manufacturing

As global awareness of environmental issues grows, many wholesale mesh manufacturers are adopting sustainable practices. This includes using recycled materials, minimizing waste during production, and implementing energy-efficient processes. By moving towards sustainable manufacturing, companies not only meet regulatory requirements but also cater to the increasing consumer demand for eco-friendly products.

Additionally, innovations in materials science are paving the way for the development of biodegradable or recyclable mesh products, further reducing the environmental impact and promoting a circular economy.

Conclusion

In summary, wholesale mesh manufacturing is a dynamic and essential part of many industries. The diversity of products, the emphasis on quality control, economic benefits, and a growing commitment to sustainability highlight the significance of this sector. As technology advances and consumer preferences shift, the mesh manufacturing industry is poised for continued growth and innovation, ensuring its relevance in the modern marketplace. Whether for industrial use or consumer goods, the importance of quality mesh products cannot be understated, making wholesale mesh manufacturing a cornerstone of contemporary manufacturing practices.

share

-

CE Certified 250 Micron SS Mesh: Precision & Durability

NewsAug.15,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.14,2025

-

Precision CE Certified 250 Micron Stainless Steel Mesh

NewsAug.13,2025

-

CE Certified Metal Fine Mesh & Screen Fabric | Top Quality

NewsAug.12,2025

-

Premium CE Certified 250 Micron Stainless Steel Mesh

NewsAug.11,2025

-

CE Certified Stainless Steel Wire Mesh for Screen Printing

NewsAug.10,2025