Jun . 19, 2024 03:19 Back to list

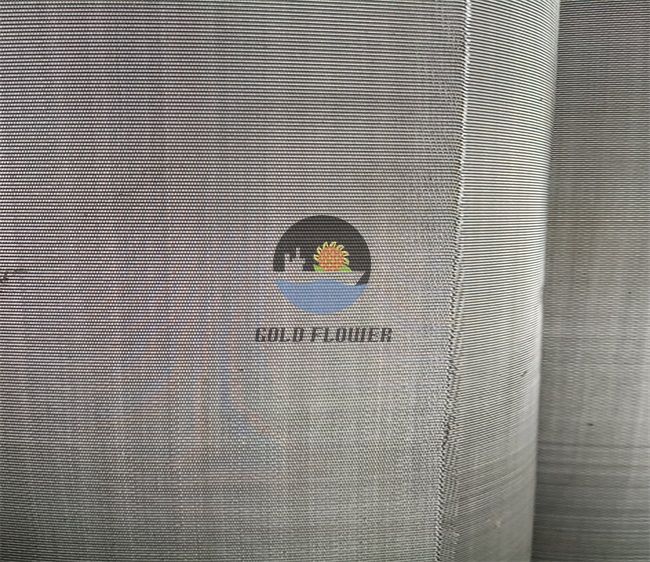

Mesh filter for OEM, ensuring superior performance.

Understanding the Significance of OEM Filter Mesh in Industrial Processes

In the realm of industrial machinery and equipment, filtration systems play a pivotal role in ensuring optimal performance and longevity. A key component within these systems is the OEM (Original Equipment Manufacturer) filter mesh, an often overlooked yet indispensable element. This article delves into the intricacies of OEM filter mesh, its function, types, and its significance in various industries.

An OEM filter mesh, as the name suggests, is a filtering component specifically designed and manufactured by the original equipment manufacturer to meet the exact specifications and requirements of their machinery. It acts as a sieve, capturing particles and impurities from fluids or gases, thereby preventing contamination and damage to sensitive components within the system.

The mesh construction varies depending on the application it serves. It can be made from a variety of materials such as stainless steel, bronze, aluminum, or plastic, each with unique properties that cater to specific filtration needs. The mesh count, or the number of openings per linear inch, determines the particle size that the filter can effectively trap. Higher mesh counts indicate smaller openings, capable of filtering finer particles.

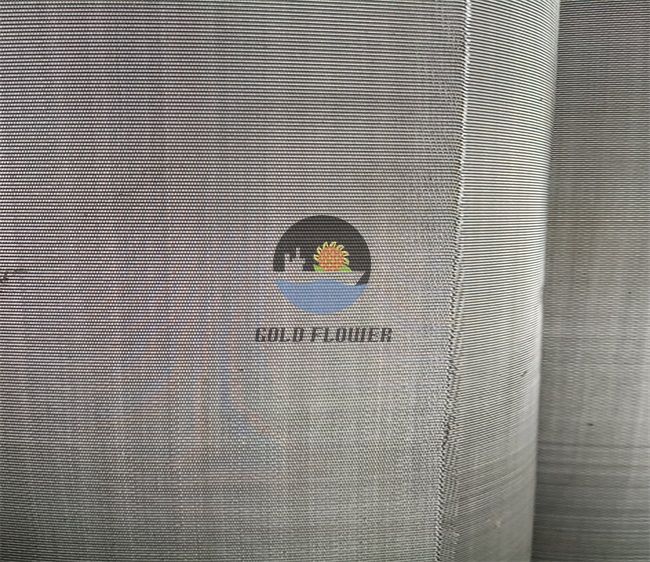

In the automotive industry, OEM filter meshes are crucial for engine protection. They safeguard oil and fuel systems by removing contaminants, enhancing engine efficiency, and prolonging its life. In pharmaceuticals, they ensure the purity of substances during production, adhering to stringent quality control standards. In the food and beverage sector, they prevent foreign objects from entering the final product, maintaining safety and hygiene In the food and beverage sector, they prevent foreign objects from entering the final product, maintaining safety and hygiene In the food and beverage sector, they prevent foreign objects from entering the final product, maintaining safety and hygiene In the food and beverage sector, they prevent foreign objects from entering the final product, maintaining safety and hygiene

In the food and beverage sector, they prevent foreign objects from entering the final product, maintaining safety and hygiene In the food and beverage sector, they prevent foreign objects from entering the final product, maintaining safety and hygiene oem filter mesh.

The importance of using OEM filter meshes cannot be overstated. These filters are tailor-made to work seamlessly with the equipment they're designed for, ensuring maximum compatibility and efficiency. They are often more durable and reliable than generic alternatives, reducing maintenance costs and downtime. Moreover, using non-OEM filters can void warranties, highlighting the importance of sticking to the manufacturer's recommendations.

However, proper maintenance and timely replacement of OEM filter meshes are vital. Clogged or damaged meshes can lead to reduced efficiency, increased pressure drop, and potential equipment failure. Regular inspection and cleaning, as per the manufacturer's guidelines, can prevent such issues.

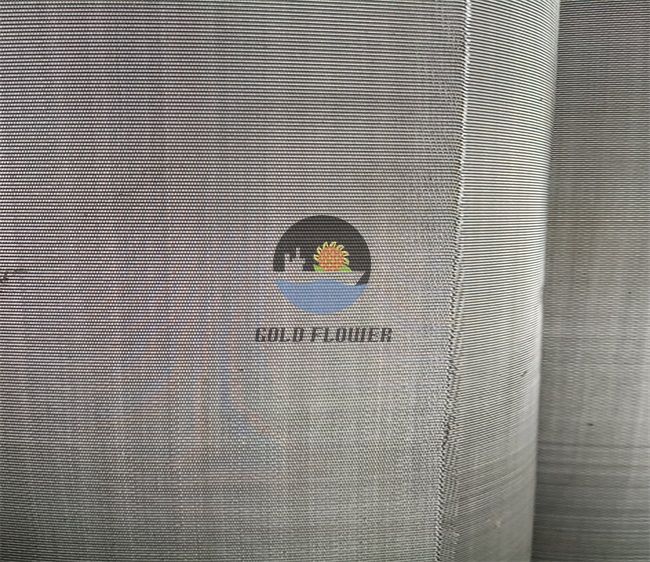

In conclusion, the OEM filter mesh is a critical element in numerous industrial processes, providing a barrier against contaminants while ensuring the smooth operation and longevity of machinery. Its importance extends beyond mere filtration, contributing significantly to overall productivity, cost-effectiveness, and safety in various industries. Recognizing and understanding the value of this often-overlooked component is essential for efficient and sustainable operations.

oem filter mesh.

The importance of using OEM filter meshes cannot be overstated. These filters are tailor-made to work seamlessly with the equipment they're designed for, ensuring maximum compatibility and efficiency. They are often more durable and reliable than generic alternatives, reducing maintenance costs and downtime. Moreover, using non-OEM filters can void warranties, highlighting the importance of sticking to the manufacturer's recommendations.

However, proper maintenance and timely replacement of OEM filter meshes are vital. Clogged or damaged meshes can lead to reduced efficiency, increased pressure drop, and potential equipment failure. Regular inspection and cleaning, as per the manufacturer's guidelines, can prevent such issues.

In conclusion, the OEM filter mesh is a critical element in numerous industrial processes, providing a barrier against contaminants while ensuring the smooth operation and longevity of machinery. Its importance extends beyond mere filtration, contributing significantly to overall productivity, cost-effectiveness, and safety in various industries. Recognizing and understanding the value of this often-overlooked component is essential for efficient and sustainable operations.

In the food and beverage sector, they prevent foreign objects from entering the final product, maintaining safety and hygiene In the food and beverage sector, they prevent foreign objects from entering the final product, maintaining safety and hygiene

In the food and beverage sector, they prevent foreign objects from entering the final product, maintaining safety and hygiene In the food and beverage sector, they prevent foreign objects from entering the final product, maintaining safety and hygiene oem filter mesh.

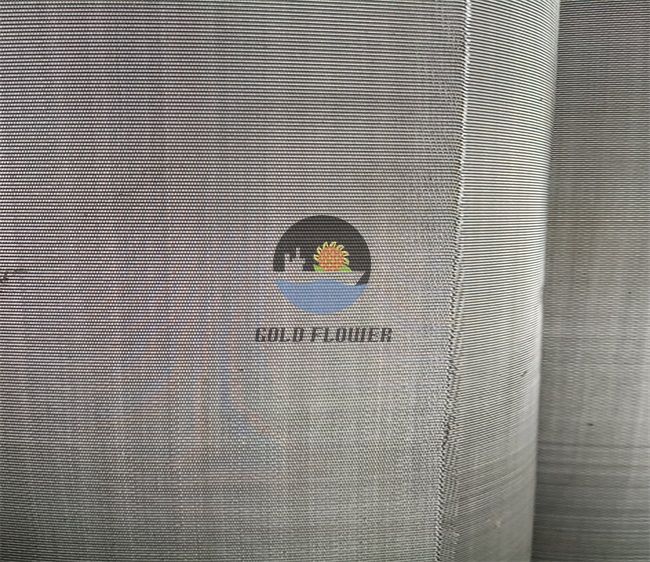

The importance of using OEM filter meshes cannot be overstated. These filters are tailor-made to work seamlessly with the equipment they're designed for, ensuring maximum compatibility and efficiency. They are often more durable and reliable than generic alternatives, reducing maintenance costs and downtime. Moreover, using non-OEM filters can void warranties, highlighting the importance of sticking to the manufacturer's recommendations.

However, proper maintenance and timely replacement of OEM filter meshes are vital. Clogged or damaged meshes can lead to reduced efficiency, increased pressure drop, and potential equipment failure. Regular inspection and cleaning, as per the manufacturer's guidelines, can prevent such issues.

In conclusion, the OEM filter mesh is a critical element in numerous industrial processes, providing a barrier against contaminants while ensuring the smooth operation and longevity of machinery. Its importance extends beyond mere filtration, contributing significantly to overall productivity, cost-effectiveness, and safety in various industries. Recognizing and understanding the value of this often-overlooked component is essential for efficient and sustainable operations.

oem filter mesh.

The importance of using OEM filter meshes cannot be overstated. These filters are tailor-made to work seamlessly with the equipment they're designed for, ensuring maximum compatibility and efficiency. They are often more durable and reliable than generic alternatives, reducing maintenance costs and downtime. Moreover, using non-OEM filters can void warranties, highlighting the importance of sticking to the manufacturer's recommendations.

However, proper maintenance and timely replacement of OEM filter meshes are vital. Clogged or damaged meshes can lead to reduced efficiency, increased pressure drop, and potential equipment failure. Regular inspection and cleaning, as per the manufacturer's guidelines, can prevent such issues.

In conclusion, the OEM filter mesh is a critical element in numerous industrial processes, providing a barrier against contaminants while ensuring the smooth operation and longevity of machinery. Its importance extends beyond mere filtration, contributing significantly to overall productivity, cost-effectiveness, and safety in various industries. Recognizing and understanding the value of this often-overlooked component is essential for efficient and sustainable operations. share

Latest news

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025

-

Premium Stainless Steel Mosquito Mesh - Durable, Rust-Resistant Protection for Windows & Doors

NewsJul.08,2025

-

Premium Stainless Steel Garden Mesh for Lasting Durability Best & High Quality Mesh Solutions

NewsJul.07,2025

-

Gold and White Blackout Curtains – Elegant Light Blocking & Insulation for Home

NewsJul.07,2025

-

Premium Spa Filter Cartridge for Clean Water Spa Pool Filters Cartridges for Jacuzzi Durable, high-efficiency spa filter cartridge for spas and jacuzzis. Improve water quality—order your pool filter cartridge now!

NewsJul.07,2025