Aug . 16, 2024 12:22 Back to list

ODM Woven Screen Mesh Solutions for Various Industrial Applications

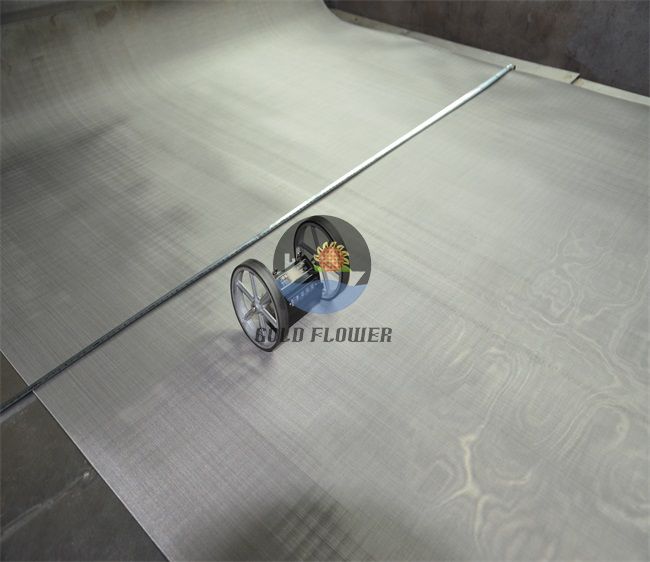

Understanding ODM Woven Screen Mesh A Comprehensive Guide

In today's industrial landscape, the demand for efficient filtration and separation solutions has increased significantly. One of the key players in this arena is the ODM (Original Design Manufacturer) woven screen mesh. This versatile product finds applications in various sectors, including mining, agriculture, food processing, and environmental protection. In this article, we will delve into the characteristics, benefits, and applications of ODM woven screen mesh, highlighting why it has become a crucial component in modern industrial operations.

What is ODM Woven Screen Mesh?

ODM woven screen mesh refers to a type of sieve or filter made from interwoven strands of metal wire or synthetic materials. The weaving process creates a fabric-like structure that allows for the effective separation of solids from liquids or the filtration of fine particles. ODM, as a concept, emphasizes the customization capabilities of manufacturers to cater their products to the specific requirements of their clients, ensuring that the woven screen mesh is designed to meet unique operational demands.

Characteristics of ODM Woven Screen Mesh

1. Material Variety ODM woven screen mesh can be made from a variety of materials, including stainless steel, carbon steel, aluminum, and synthetic fibers. The choice of material significantly affects the durability, resistance to corrosion, and overall performance of the mesh.

2. Mesh Size and Aperture The size of the mesh and the dimensions of its openings are critical factors in determining its filtration capabilities. ODM manufacturers can create custom mesh sizes to accommodate specific particle sizes, enhancing the efficiency of filtration processes.

3. Weaving Patterns Different weaving patterns, such as plain weave, twill weave, or dutch weave, offer varying degrees of strength and filtration performance. ODM companies provide options that meet the technical specifications of their clients, ensuring optimal results in various applications.

4. Durability and Longevity High-quality ODM woven screen mesh is designed to withstand harsh conditions and heavy traffic, making it a cost-effective solution for industries that require long-lasting performance.

Benefits of ODM Woven Screen Mesh

odm woven screen mesh

1. Custom Solutions One of the primary advantages of ODM woven screen mesh is the ability to tailor products to meet specific needs. This customization leads to enhanced efficiency and performance in industrial applications.

2. Improved Filtration Efficiency The precise design of ODM woven screen mesh contributes to higher filtration efficiency, resulting in cleaner end products and improved overall operational efficiency.

3. Reduced Maintenance Costs High-quality woven screen mesh tends to require less frequent replacement and maintenance. This reliability translates to lower operational costs over time.

4. Versatility With a wide range of materials, mesh sizes, and weaving patterns available, ODM woven screen mesh can be utilized in diverse applications, from filtering wastewater to processing food products.

Applications of ODM Woven Screen Mesh

1. Mining and Mineral Processing Used for screening and separating ores and minerals, woven screen mesh is integral to maintaining the quality and purity of extracted materials.

2. Agriculture In agricultural settings, woven mesh is often employed for sifting soil, filtering water, and ensuring the purity of seeds and fertilizers.

3. Food and Beverage Industry ODM woven screen mesh plays a vital role in ensuring that food products are safe and free from contaminants during processing.

4. Environmental Protection The mesh is utilized in various environmental applications, including water treatment and pollution control, helping to maintain ecological balance.

In conclusion, ODM woven screen mesh stands out as a critical solution for industries requiring efficient separation and filtration. With its customizable features, durable materials, and extensive applications, it meets the needs of modern industrial operations, making it an invaluable asset across numerous sectors. Whether you’re in mining, agriculture, food processing, or environmental management, investing in high-quality ODM woven screen mesh can significantly enhance your operational efficiency and product quality.

share

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025

-

Premium Stainless Steel Mosquito Mesh - Durable, Rust-Resistant Protection for Windows & Doors

NewsJul.08,2025

-

Premium Stainless Steel Garden Mesh for Lasting Durability Best & High Quality Mesh Solutions

NewsJul.07,2025

-

Gold and White Blackout Curtains – Elegant Light Blocking & Insulation for Home

NewsJul.07,2025

-

Premium Spa Filter Cartridge for Clean Water Spa Pool Filters Cartridges for Jacuzzi Durable, high-efficiency spa filter cartridge for spas and jacuzzis. Improve water quality—order your pool filter cartridge now!

NewsJul.07,2025