Nov . 26, 2024 05:00 Back to list

ODM Dutch Wire Mesh for Innovative and Secure Industrial Applications

Understanding ODM Dutch Wire Mesh A Comprehensive Guide

In the world of industrial materials, wire mesh plays a crucial role in various applications, ranging from construction to filtration. Among the diverse options available, ODM Dutch wire mesh stands out due to its unique construction and versatile applications. In this article, we will explore the characteristics, uses, and benefits of ODM Dutch wire mesh, making it easier for you to understand why it is a preferred choice in many industries.

What is ODM Dutch Wire Mesh?

ODM Dutch wire mesh is a type of woven wire mesh characterized by its distinct weaving pattern and wire gauge. It typically consists of two layers of wire a fine wire that forms the warp and a thicker wire that makes up the weft. This combination provides enhanced strength and durability. Generally made from high-quality stainless steel, carbon steel, or other alloys, Dutch wire mesh is resistant to corrosion and wear, making it ideal for challenging environments.

Characteristics of ODM Dutch Wire Mesh

One of the key characteristics of ODM Dutch wire mesh is its tight weave, which presents a flat surface on one side. This is especially advantageous in applications where a smooth finish is required. The tight weave also ensures that the mesh offers excellent filtration capabilities, making it suitable for various industries such as food processing, pharmaceuticals, and petrochemicals.

Additionally, the mesh is versatile in terms of customization. It can be manufactured in various wire diameters, mesh openings, and dimensions to accommodate specific requirements. The ability to produce tailor-made solutions makes ODM Dutch wire mesh a favored choice in projects with unique specifications.

Applications of ODM Dutch Wire Mesh

ODM Dutch wire mesh is widely used across various industries. Here are some notable applications

1. Filtration One of the primary uses of ODM Dutch wire mesh is in filtration systems. Its fine mesh structure allows it to effectively separate solids from liquids and gases. This is vital in industries that require purity, such as water treatment, food processing, and chemical manufacturing.

2. Vibration Control In mining and quarrying, ODM Dutch wire mesh is employed for controlling vibrations during material processing. This helps in reducing the wear and tear of equipment while also ensuring a safer working environment.

odm dutch wire mesh

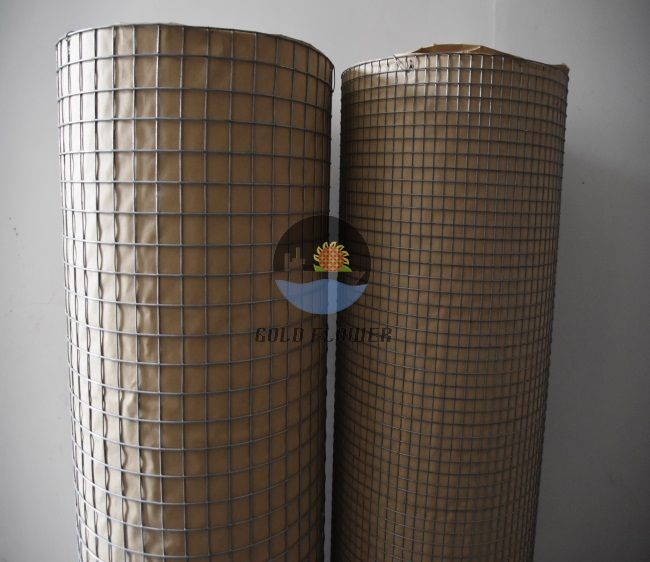

3. Protective Barriers The strength and durability of this wire mesh make it an excellent option for protective barriers. Whether for security fencing or supporting structures in construction, ODM Dutch wire mesh provides reliable protection against intruders or debris.

4. Architectural Applications The aesthetic appeal of wire mesh has led to its use in architectural designs. ODM Dutch wire mesh can be used for decorative facades, sunshades, and partitions, offering both function and style in modern architecture.

5. Conveyor Systems In manufacturing, ODM Dutch wire mesh is used in conveyor systems to transport goods safely and efficiently. Its strength allows it to handle heavy loads while maintaining stability.

Benefits of ODM Dutch Wire Mesh

1. Durability The materials used in ODM Dutch wire mesh are highly durable, offering resistance to rust, corrosion, and mechanical stress. This ensures a long lifespan, making it a cost-effective option in the long run.

2. Versatility The ability to customize wire diameter and mesh openings allows ODM Dutch wire mesh to meet a wide array of applications. This versatility ensures that it can be adapted to specific project needs.

3. Effective Filtration The fine openings provide effective filtration capabilities, making it a go-to material in various processing industries.

4. Easy Installation The lightweight nature of the mesh, combined with its flexible design, makes installation straightforward and hassle-free.

5. Aesthetic Appeal For architectural projects, the sleek appearance of ODM Dutch wire mesh allows for attractive designs, blending functionality with aesthetics seamlessly.

Conclusion

In conclusion, ODM Dutch wire mesh is an integral part of many industries due to its unique characteristics and versatility. Its applications range from industrial filtration to architectural design, showcasing its importance in both functionality and aesthetics. As industries continue to evolve, the demand for high-quality materials like ODM Dutch wire mesh will undoubtedly grow, making it a significant player in the industrial landscape. By investing in ODM Dutch wire mesh, businesses can ensure durability, efficiency, and quality in their projects.

share

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025

-

CE Certification Buy Wire Mesh Fence for High Security and Durability

NewsJul.30,2025