Oct . 13, 2024 06:33 Back to list

Wire Mesh Manufacturing Process for ODM Applications and Innovations in Production Techniques

The Production of ODM Wire Mesh A Comprehensive Overview

In the world of industrial manufacturing, wire mesh is an essential component utilized in a myriad of applications ranging from construction to agriculture, and filtration to security. One key aspect of wire mesh production is ODM (Original Design Manufacturer), which plays a crucial role in customizing products to meet specific client requirements. In this article, we will explore the intricacies of ODM wire mesh production, looking at the processes, materials, and benefits associated with it.

Understanding ODM in Wire Mesh Production

ODM refers to companies that design and manufacture products that are later branded by another company for sale. In the context of wire mesh, an ODM supplier may take a client's specifications — whether it be dimensions, material types, or specific designs — and produce tailored wire mesh solutions accordingly. This model is particularly beneficial for businesses that may lack the resources for in-house production or design but seek high-quality, customized products.

The Production Process of ODM Wire Mesh

The production of wire mesh involves several key steps, beginning with the selection of materials. Common materials used in wire mesh production include stainless steel, low carbon steel, and galvanized steel. Each material brings its own set of properties, such as corrosion resistance, strength, and flexibility, making it imperative for clients to choose the right material based on their application needs.

1. Material Sourcing The process begins with sourcing raw materials. ODM manufacturers often work closely with suppliers to ensure that the wire used meets industry standards and specifications.

2. Wire Drawing After material sourcing, the next step is wire drawing, where the metal is processed to create wire of desired thickness. This step includes reducing the diameter of the metal rod through a series of dies, making it thinner and longer.

3. Mesh Weaving The drawn wire is then woven together to create mesh. This can be done using various weaving techniques such as plain weave, twill weave, or Dutch weave, each providing different levels of strength and filtration capabilities. Additionally, ODM providers can customize the weaving pattern to match specific project requirements.

4. Post-processing Once the mesh is woven, it may undergo various post-processing treatments. This includes galvanizing (for corrosion resistance), annealing (for flexibility), or PVC coating (for increased durability). ODM manufacturers might also provide surface treatments to enhance the aesthetic appeal of the wire mesh.

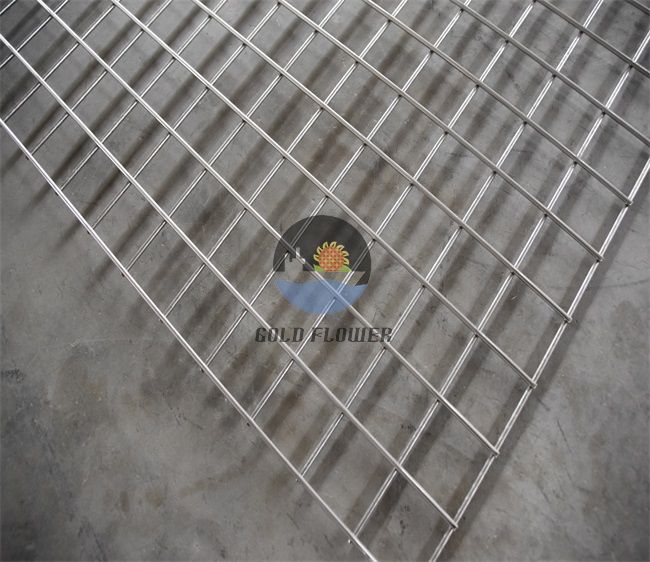

odm wire mesh production

5. Quality Control Quality control is a critical part of the production process. Each batch of wire mesh undergoes rigorous testing to ensure that it meets the specified parameters regarding strength, size, and finish. This helps avoid defects and ensures customer satisfaction.

6. Packaging and Delivery Finally, the wire mesh products are packaged appropriately for shipping. ODM manufacturers often take special care to ensure that products are secured and protected during transportation to prevent damage.

Benefits of ODM Wire Mesh Production

1. Customization One of the primary benefits of ODM wire mesh production is the level of customization available. Clients can specify their unique requirements, whether it’s the size, material, or design, ensuring the final product perfectly suits their needs.

2. Cost-effectiveness Outsourcing production to an ODM can be more cost-effective than managing production in-house. Companies can save on labor costs, overhead, and equipment while still getting high-quality products.

3. Expertise ODM manufacturers typically have extensive experience and expertise in wire mesh production. They stay up-to-date with industry innovations and standards, which translates into better products for clients.

4. Scalability ODM production processes can adapt to various scales of production, allowing businesses to increase or decrease their order quantities based on demand without displacing operational efficiency.

5. Faster time-to-market By leveraging the capabilities of an ODM manufacturer, companies can bring their products to market more quickly. This is crucial in industries where timing is everything.

Conclusion

The production of ODM wire mesh is a multifaceted process that emphasizes customization, quality, and efficiency. As industries continue to evolve, the demand for specialized wire mesh products will likely increase, making ODM partnerships increasingly valuable. By understanding the production process and benefits associated with ODM wire mesh, businesses can make informed decisions that enhance their operational capabilities and meet market needs effectively. Whether it’s for construction, filtration, or other applications, ODM wire mesh stands as a testament to the innovation and collaboration within the manufacturing sector.

share

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025

-

Premium Stainless Steel Mosquito Mesh - Durable, Rust-Resistant Protection for Windows & Doors

NewsJul.08,2025

-

Premium Stainless Steel Garden Mesh for Lasting Durability Best & High Quality Mesh Solutions

NewsJul.07,2025

-

Gold and White Blackout Curtains – Elegant Light Blocking & Insulation for Home

NewsJul.07,2025

-

Premium Spa Filter Cartridge for Clean Water Spa Pool Filters Cartridges for Jacuzzi Durable, high-efficiency spa filter cartridge for spas and jacuzzis. Improve water quality—order your pool filter cartridge now!

NewsJul.07,2025