Jul . 26, 2024 09:21 Back to list

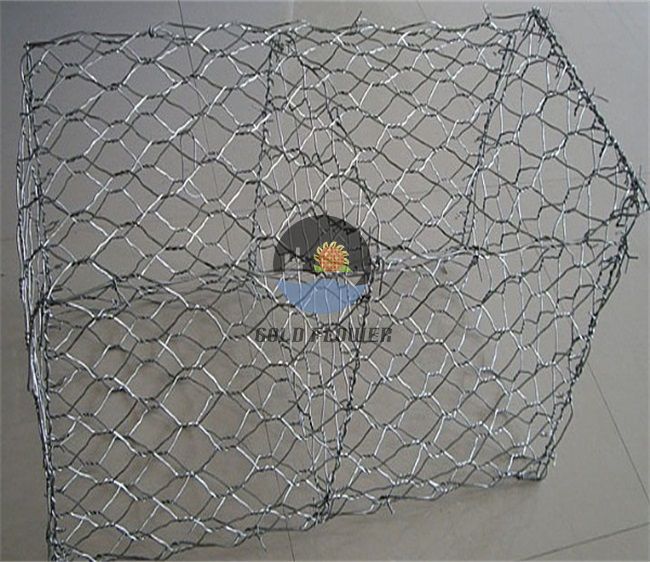

OEM 3 Inch Mesh Fabric for Versatile Applications in Industrial and Commercial Use

Understanding OEM 3 Inch Mesh An Essential Component in Manufacturing

In today's rapidly evolving industrial landscape, Original Equipment Manufacturers (OEMs) play a pivotal role in ensuring that high-quality components are delivered to various sectors. One such component that has gained significant traction in recent years is the 3-inch mesh. This versatile product serves numerous applications across different industries, making it an essential item in many manufacturing processes.

What is OEM 3 Inch Mesh?

At its core, OEM 3 inch mesh refers to a specific type of mesh material produced to meet unique specifications for various manufacturing needs. The term 3 inch typically denotes the size or spacing of the mesh openings, which can vary depending on the requirements of the end product. This type of mesh is often made from materials such as stainless steel, aluminum, or synthetic fibers, each chosen for its strength, durability, and resistance to environmental factors.

Applications of 3 Inch Mesh

The versatility of 3-inch mesh makes it a popular choice for a wide range of applications. In the construction industry, for instance, it is frequently used in concrete reinforcement and scaffolding. The mesh provides additional strength and stability, ensuring that structures can withstand various stresses.

In agriculture, 3-inch mesh serves various purposes, including fencing, crop protection, and soil erosion control. Its ability to withstand harsh weather conditions while providing essential support makes it a go-to choice for farmers and land developers alike.

Moreover, the automotive and aerospace industries have also recognized the benefits of 3-inch mesh. Its lightweight yet robust structure is ideal for applications such as air filters, sound dampening systems, and safety mesh for vehicles. As these industries continue to innovate, the demand for specialized mesh components is likely to grow, driving further advancements in mesh technology.

oem 3 inch mesh

Benefits of Using OEM 3 Inch Mesh

1. Customizability OEMs can manufacture 3-inch mesh to specific requirements, ensuring that clients receive products tailored to their unique needs. This customizability extends to the choice of materials, dimensions, and even the mesh’s weave pattern.

2. Durability The materials used in producing 3-inch mesh are chosen for their high resistance to corrosion and wear. This longevity reduces the need for frequent replacements, which can save on costs and labor.

3. Versatile Use The applications of 3-inch mesh extend beyond the initial industries mentioned. It can be found in filtration systems, architectural design, and even in artistic endeavors, showcasing its adaptability and usability across various fields.

4. Enhanced Safety In many applications, especially in construction and automotive parts, 3-inch mesh provides an additional layer of safety. By ensuring structural integrity and reducing the risk of failure, it plays a crucial role in protecting both goods and individuals.

Conclusion

In conclusion, OEM 3 inch mesh is far more than just a simple composite material; it is an integral part of many manufacturing processes across diverse industries. Its customizability, durability, versatility, and safety benefits make it a preferred choice for OEMs and end-users alike. As industrial demands continue to evolve, the significance of specialized components like 3-inch mesh will only increase, heralding a new era of innovation in manufacturing. Whether in construction, agriculture, automotive, or beyond, the importance of quality mesh products cannot be overstated. As we look to the future, the role of OEMs in supplying these critical components will undoubtedly be a cornerstone of advancements in technology and industrial capability.

share

-

High-Performance Particle Filters: Optimal Mediums & Applications

NewsAug.18,2025

-

Competitive Screen Mesh Price | 1/4", 1/8", 1/2" Wire Mesh Screens

NewsAug.17,2025

-

CE Certified 250 Micron SS Mesh: Precision & Durability

NewsAug.15,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.14,2025

-

Precision CE Certified 250 Micron Stainless Steel Mesh

NewsAug.13,2025

-

CE Certified Metal Fine Mesh & Screen Fabric | Top Quality

NewsAug.12,2025