Dec . 10, 2024 13:08 Back to list

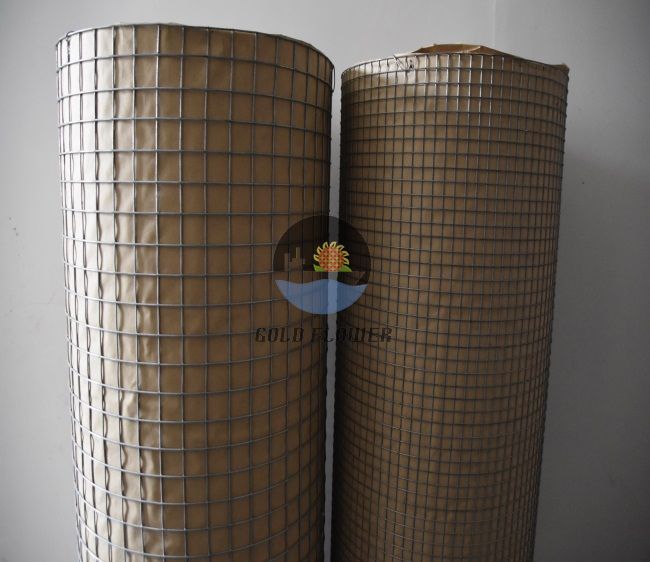

oem coated wire mesh factories

The Importance of OEM Coated Wire Mesh Factories in Modern Manufacturing

In today's fast-paced manufacturing environment, the demand for specialized components is greater than ever. One significant player in this arena is the OEM (Original Equipment Manufacturer) coated wire mesh factories. These facilities are pivotal in providing customized wire mesh solutions that cater to various industries, including construction, agriculture, food processing, and automotive sectors. This article explores the role, benefits, and significance of OEM coated wire mesh factories in modern manufacturing.

What is OEM Coated Wire Mesh?

OEM coated wire mesh refers to wire mesh products that are manufactured according to the specifications and standards set by a client. Coating can involve various materials such as PVC, epoxy, or other protective substances, enhancing the wire mesh's durability, corrosion resistance, and aesthetic appeal. The ability to tailor mesh specifications—such as size, coating type, and mesh density—makes OEM manufacturers invaluable.

Industry Applications

OEM coated wire mesh finds applications across a wide array of industries

1. Construction In the construction sector, coated wire mesh is used for reinforcing concrete, providing structural support that enhances durability. It also serves as a safety barrier on construction sites and as a framework for fences and grating. 2. Agriculture Farmers utilize coated wire mesh for fencing livestock, crop protection, and creating mesh cages for poultry. The protective coating ensures that the mesh withstands harsh weather conditions, prolonging its lifespan.

3. Food Processing The food industry demands high hygiene standards, and coated wire mesh can be specially designed for use in food packaging, processing equipment, and storage solutions. The non-reactive coatings ensure that there’s no contamination, making it ideal for sensitive environments.

oem coated wire mesh factories

4. Automotive In the automotive realm, OEM coated wire mesh can be found in filters, grilles, and various components requiring strong yet lightweight materials. Customizability allows manufacturers to meet stringent automotive standards efficiently.

Advantages of Using OEM Coated Wire Mesh

1. Customization One of the primary advantages of working with OEM factories is the ability to customize products. Manufacturers can specify dimensions, coatings, and other properties to precisely meet their needs, providing a tailored solution for their applications.

2. Quality Assurance OEM coated wire mesh facilities often adhere to stringent quality control measures. This assurance results in improved product performance, ensuring the mesh can withstand relevant stressors in its operating environment.

3. Cost-Effectiveness By sourcing directly from OEM manufacturers, companies can save money in both production costs and labor. It reduces the need for extensive inventory, as manufacturers can produce the required quantity as needed.

4. Innovation OEM factories often invest in the latest technologies and materials, allowing for innovations in product design and functionality. This can lead to enhanced performance traits, such as increased tensile strength and better corrosion resistance.

Conclusion

The significance of OEM coated wire mesh factories cannot be overstated. As industries continue to evolve and demand more specialized products, the role of these manufacturers becomes increasingly critical. Their ability to provide tailored, high-quality solutions not only enhances manufacturing efficiency but also drives innovation across various sectors. As businesses seek to improve productivity and sustainability, collaborating with OEM coated wire mesh factories will likely be a strategic move for many manufacturers looking to stay competitive in the modern marketplace.

share

-

CE Certified 250 Micron Stainless Steel Mesh | Precision & Durability

NewsAug.27,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision & Durability

NewsAug.26,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision & Durability

NewsAug.25,2025

-

Premium CE Certified Metal Fine Mesh for Precision & Safety

NewsAug.24,2025

-

Stainless Steel Wedge Wire Mesh: Durable, Precision Filtration

NewsAug.23,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision Filtration

NewsAug.22,2025