Dec . 31, 2024 09:23 Back to list

OEM Copper Woven Wire Cloth for Versatile Applications in Various Industries

The Versatility and Applications of OEM Copper Woven Wire Cloth

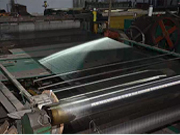

In the vast world of industrial materials, copper woven wire cloth stands out for its unique combination of properties and diverse applications. This material, often produced through OEM (Original Equipment Manufacturing) processes, offers a range of benefits that make it a preferred choice in numerous sectors, from electronics to architecture.

Understanding Copper Woven Wire Cloth

Copper woven wire cloth is made from copper wire that is woven together to form a mesh-like fabric. The weaving process can vary in terms of weave pattern, wire diameter, and mesh size, allowing for customization based on specific needs. The resulting product possesses excellent conductivity, strength, and resistance to corrosion, making it highly sought after in various applications.

Key Properties of Copper Woven Wire Cloth

1. Electrical Conductivity One of the most notable features of copper is its high electrical conductivity, which is second only to silver. This property makes copper woven wire cloth an ideal choice for applications that require effective electrical grounding and shielding.

2. Thermal Conductivity Similar to its electrical attributes, copper also boasts excellent thermal conductivity, which can be advantageous in thermal management solutions, dissipating heat effectively in electronics and other systems.

3. Corrosion Resistance Although copper can oxidize and form a patina, its natural resistance to corrosion makes it suitable for various environmental applications. When treated or alloyed, the corrosion resistance can be significantly enhanced.

4. Flexibility and Ductility Copper is known for its flexibility and ductility, allowing the woven wire cloth to be easily shaped or formed. This makes it an excellent option for intricate designs and structures.

Applications of Copper Woven Wire Cloth

The versatility of copper woven wire cloth means it finds applications in numerous fields

1. Electronics In the electronics industry, copper woven wire cloth is commonly used for EMI (electromagnetic interference) shielding, ensuring that electronic devices function without interference from external signals. Additionally, it is used in connectors and grounding solutions.

oem copper woven wire cloth

2. Architecture and Design Architects and designers increasingly use copper wire cloth in interior and exterior designs. Its aesthetic appeal, combined with functional properties, makes it an attractive choice for decorative applications, such as facades, screens, and railings.

3. Filtration Copper woven wire cloth is employed in filtration systems, particularly where antimicrobial properties are advantageous. Its ability to filter out particles while resisting bacterial growth makes it suitable for water treatment and air filtration applications.

4. Automotive Industry In the automotive sector, the durability and conductivity of copper woven wire cloth make it useful for various components, including sensors, electric vehicle components, and wiring harnesses.

5. Art and Craft Artists and craftspeople utilize copper woven wire cloth in sculpture, jewelry, and other creative projects, often exploiting its unique color and texture.

Advantages of OEM in Manufacturing

Choosing OEM for the production of copper woven wire cloth offers several advantages

- Customization OEM manufacturers can tailor products to meet specific customer requirements, whether it pertains to size, weave pattern, or material treatments.

- Quality Assurance OEM processes often implement stringent quality control measures, ensuring that the final product meets the required standards.

- Cost-Effectiveness By sourcing materials through OEM suppliers, companies can often reduce costs through bulk purchasing and streamlined production methods.

Conclusion

Copper woven wire cloth represents a fusion of functionality and versatility, making it a valuable asset in many industries. Its unique properties—ranging from exceptional conductivity to corrosion resistance—coupled with the advantages of OEM manufacturing, highlight its importance in modern applications. As technology continues to advance and industries evolve, the demand for high-quality copper woven wire cloth is expected to grow, cementing its place as a crucial material in various fields. Whether for industrial use, architectural innovation, or artistic expression, copper woven wire cloth remains a testament to the enduring utility of this remarkable metal.

share

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025

-

CE Certification Buy Wire Mesh Fence for High Security and Durability

NewsJul.30,2025

-

Stainless Steel Mesh Filter Discs for Precise Filtration Solutions

NewsJul.29,2025