Dec . 26, 2024 18:32 Back to list

oem mesh net metal

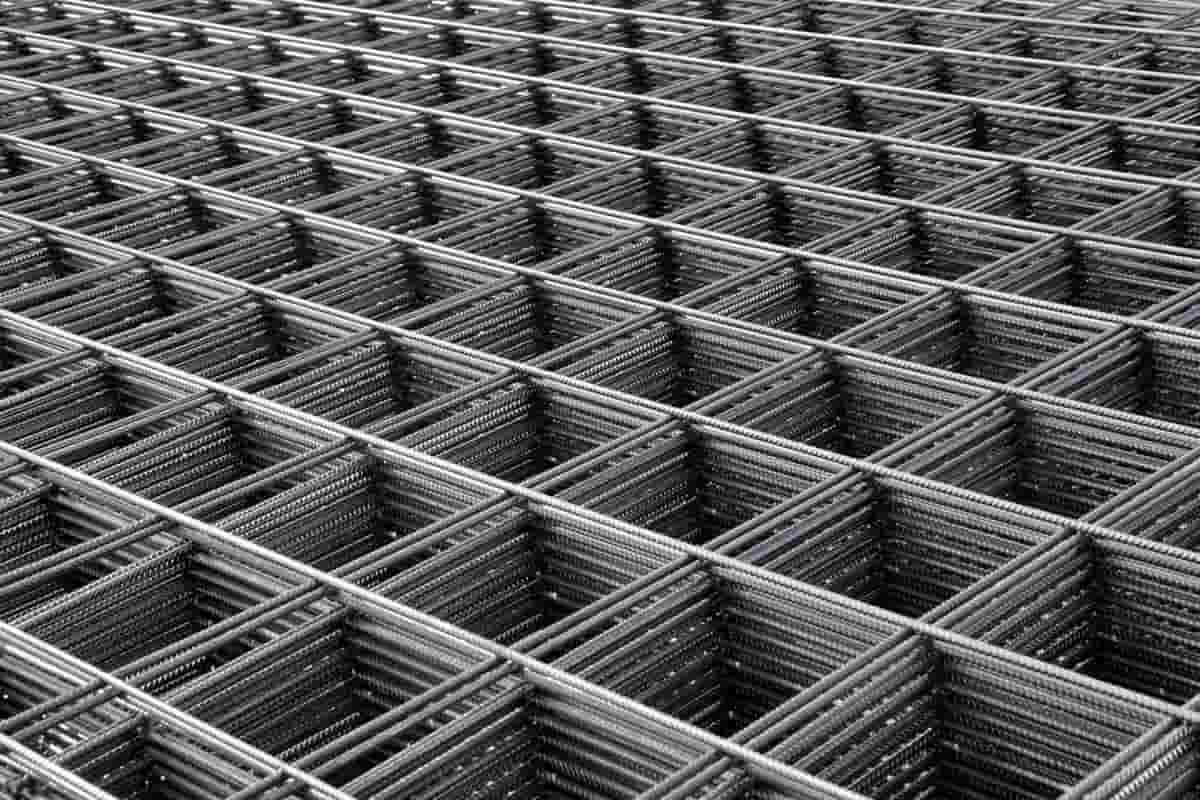

The Versatility and Applications of OEM Mesh Net Metal

In today's fast-paced industrial landscape, the demand for versatile materials continues to rise. One such material that has found its place across various sectors is OEM mesh net metal. This innovative product is a type of metal mesh that can be customized for Original Equipment Manufacturers (OEM) to meet the specific needs of diverse applications. Its unique properties and functional capabilities make it an essential asset in a range of industries, from construction to aerospace.

What is OEM Mesh Net Metal?

OEM mesh net metal refers to a type of woven or welded mesh made from high-quality metal materials such as stainless steel, aluminum, or carbon steel. This product is characterized by its open framework, which allows for light, air, and other substances to pass through while offering durability and strength. The term OEM indicates that this product is designed to meet unique specifications set by manufacturers for their specific applications, making it a highly customizable solution.

Characteristics and Benefits

One of the primary advantages of OEM mesh net metal is its excellent strength-to-weight ratio. This property allows it to maintain structural integrity while being lightweight, making it easier to handle and install in various applications. Furthermore, its corrosion resistance, particularly in the case of stainless steel variants, enhances its longevity, making it suitable for outdoor and industrial environments where exposure to moisture and chemicals is inevitable.

Another important characteristic of OEM mesh net metal is its versatility. It can be manufactured in a range of mesh sizes, wire diameters, and configurations to meet specific requirements. This adaptability allows it to be used for various applications, such as filtering, reinforcement, and safety barriers. For example, fine mesh options can be used in filtration systems for liquid and air applications, while larger openings might serve in construction projects as safety barriers or scaffolding.

Applications Across Industries

oem mesh net metal

The applications of OEM mesh net metal are vast and varied. In the construction industry, it is commonly used for shoring, scaffolding, and reinforcement in walls and concrete structures. The mesh provides necessary support while minimizing weight and maintaining easy workability.

In the automotive sector, OEM mesh net metal finds its use in components such as air filter screens and structural reinforcements. The mesh helps improve airflow while providing additional support, which is essential for performance and safety.

The aerospace industry also utilizes this material. OEM mesh net metal plays a crucial role in lightweight structural components, helping in weight reduction while maintaining safety and compliance with stringent industry standards.

Moreover, in agriculture and horticulture, metal mesh is used for creating protective barriers against pests and animals, ensuring crops remain safe while allowing light and air to reach the plants.

In the HVAC sector, OEM mesh net metal is often used in filters and ductwork, promoting airflow while effectively trapping dust and particulate matter, leading to improved air quality.

The Future of OEM Mesh Net Metal

As industries continue to evolve and prioritize sustainability, the development of OEM mesh net metal is poised to expand further. Innovations in manufacturing processes, such as automated welding and advancements in metal formation techniques, will enhance the quality and versatility of this material. Furthermore, increased recycling capabilities for metal can contribute to a more sustainable supply chain, appealing to environmentally conscious manufacturers.

In conclusion, OEM mesh net metal is a crucial material that serves a wide range of applications across multiple sectors, owing to its strength, customization potential, and durability. As the demand for flexible and efficient materials grows, OEM mesh net metal will undoubtedly continue to play a pivotal role in shaping the future of manufacturing and construction. Its ability to adapt and meet specific OEM requirements ensures it remains a vital asset for industries looking for innovative solutions to meet modern challenges.

share

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025

-

Premium Stainless Steel Mosquito Mesh - Durable, Rust-Resistant Protection for Windows & Doors

NewsJul.08,2025

-

Premium Stainless Steel Garden Mesh for Lasting Durability Best & High Quality Mesh Solutions

NewsJul.07,2025

-

Gold and White Blackout Curtains – Elegant Light Blocking & Insulation for Home

NewsJul.07,2025

-

Premium Spa Filter Cartridge for Clean Water Spa Pool Filters Cartridges for Jacuzzi Durable, high-efficiency spa filter cartridge for spas and jacuzzis. Improve water quality—order your pool filter cartridge now!

NewsJul.07,2025