Dec . 10, 2024 19:54 Back to list

High-Quality OEM 316 Stainless Steel Mesh for Various Applications

Exploring the Versatility of OEM Stainless Steel 316 Mesh

Stainless steel mesh has become an integral component across various industries, thanks to its unmatched strength, durability, and resistance to corrosion. Among the many types of stainless steel meshes available, OEM stainless steel 316 mesh stands out due to its specific material composition and unique properties. This article will delve into what makes 316 stainless steel mesh a preferred choice, its applications, and the advantages of opting for Original Equipment Manufacturer (OEM) products.

Understanding Stainless Steel 316

Stainless steel 316 is an austenitic alloy that contains molybdenum, which enhances its resistance to corrosion, especially in chloride environments. This characteristic makes it suitable for marine applications, chemical processing, and in any setting where mild steel would quickly deteriorate. The addition of molybdenum also improves the steel’s high-temperature strength, extending its use in challenging thermal conditions.

Why Choose OEM Stainless Steel 316 Mesh?

Selecting OEM stainless steel 316 mesh guarantees that you are getting high-quality, standardized products often tailored to meet specific industry requirements. OEM manufacturers follow stringent quality control processes and industry regulations, ensuring that their products are reliable and efficient. Their experience and expertise allow them to accommodate unique specifications, making it easier for businesses to integrate these meshes into their applications.

Applications of OEM Stainless Steel 316 Mesh

The versatility of stainless steel 316 mesh allows it to serve diverse functions across various industries

1. Filtration Stainless steel 316 mesh is commonly used in filtration systems. The fine mesh is perfect for filtering liquids and gases in chemical manufacturing, pharmaceuticals, and food processing. Its durability ensures that it can withstand the demanding conditions of these processes.

2. Separation In mining and mineral processing, 316 mesh is utilized for separating particles based on size. Its robust structure allows it to endure harsh environments while effectively performing its function.

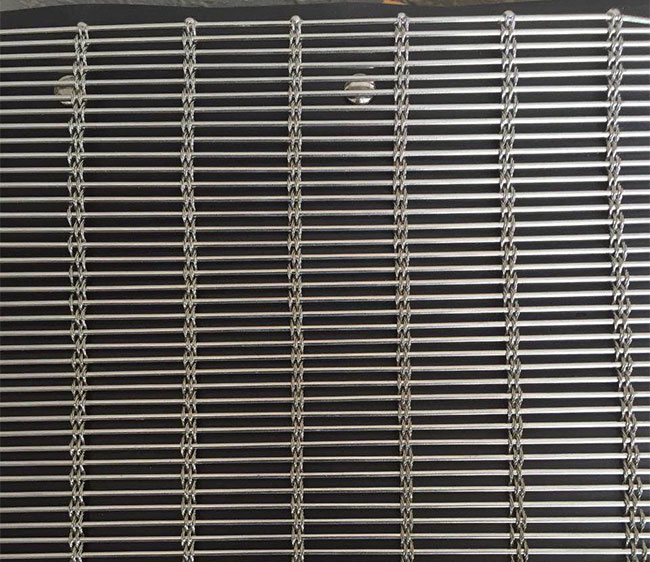

3. Architecture and Design Due to its aesthetic appeal and high durability, OEM stainless steel 316 mesh is increasingly being used in architectural applications, such as railings, facades, and screens. It acts both as a functional component and an artistic element, adding modernity and elegance to structures.

oem stainless steel 316 mesh

4. Protective Barriers In various settings, 316 mesh serves as a protective barrier, ensuring safety while providing visibility. It is often employed in security fencing and hazard barriers, safeguarding both people and property.

The Advantages of Stainless Steel 316 Mesh

Choosing OEM stainless steel 316 mesh comes with a set of advantages

- Durability The resistance to corrosion and wear ensures that the mesh has a long service life, even in challenging environments.

- Versatility It can be customized to meet specific manufacturing needs, making it suitable for various applications.

- Maintenance Stainless steel is easy to clean and maintain, which is vital in industries such as food and pharmaceuticals, where hygiene is paramount.

- Cost-Effectiveness While the initial investment might be higher than other materials, the longevity and durability of stainless steel 316 mesh often lead to reduced replacement and maintenance costs over time.

Conclusion

In summary, OEM stainless steel 316 mesh is a robust and versatile solution applicable in numerous industries. Its inherent properties, enhanced by OEM manufacturing processes, ensure that it meets the high-quality standards demanded in today’s competitive market. Whether for filtration, separation, architecture, or protection, 316 mesh continues to prove its value, driving innovations and improvements across various sectors. Choosing this material is not just about making a purchase; it is an investment in quality, durability, and reliability for the future.

share

-

CE Certified 250 Micron Stainless Steel Mesh | Precision & Durability

NewsAug.27,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision & Durability

NewsAug.26,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision & Durability

NewsAug.25,2025

-

Premium CE Certified Metal Fine Mesh for Precision & Safety

NewsAug.24,2025

-

Stainless Steel Wedge Wire Mesh: Durable, Precision Filtration

NewsAug.23,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision Filtration

NewsAug.22,2025