Nov . 23, 2024 18:15 Back to list

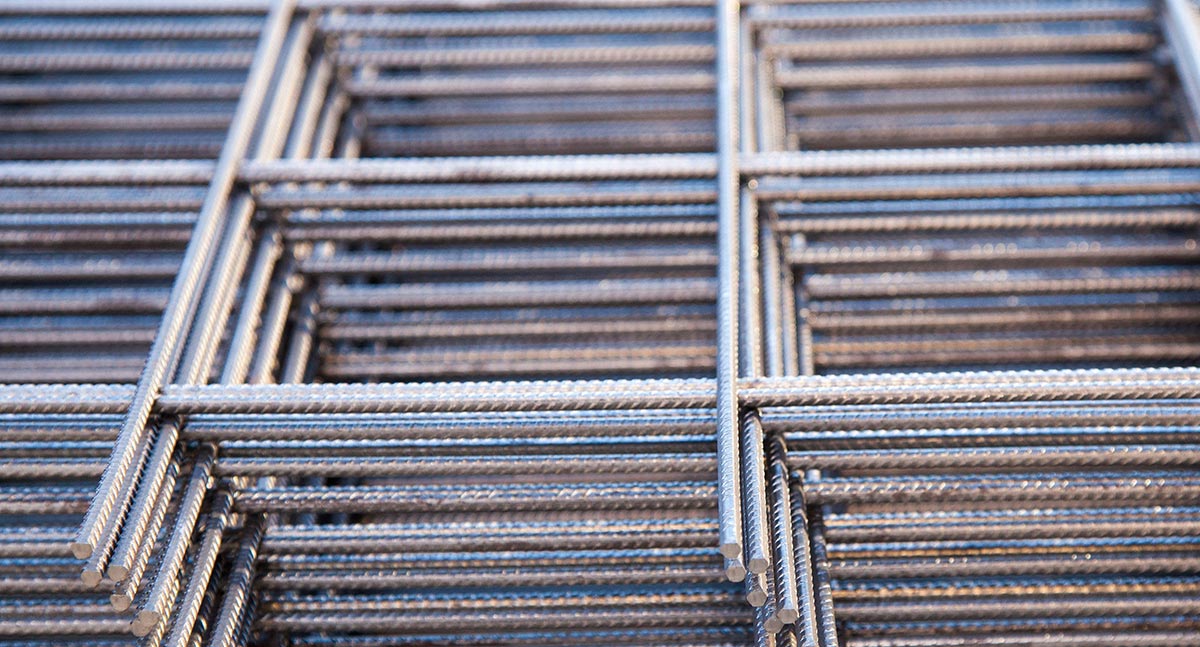

oem steel cable netting

The Significance of OEM Steel Cable Netting in Modern Industries

In today's fast-paced industrial landscape, the need for robust and reliable materials is more critical than ever. Among these materials, OEM (Original Equipment Manufacturer) steel cable netting has emerged as a prominent choice across various sectors. This article delves into the significance, applications, and benefits of OEM steel cable netting, highlighting its crucial role in enhancing safety and efficiency across different industrial operations.

What is OEM Steel Cable Netting?

OEM steel cable netting refers to customized netting solutions made from high-strength steel cables. These nets are engineered to meet specific requirements set forth by manufacturers and end-users, making them tailored solutions for various applications. The production of OEM steel cable netting involves weaving steel cables into a grid-like structure, resulting in a robust and durable framework suited for numerous industrial purposes.

Applications of OEM Steel Cable Netting

OEM steel cable netting finds its utility in a multitude of industries. Here are a few key applications

1. Construction Industry In construction, safety is paramount. Steel cable netting is often utilized as a protective barrier to prevent falls and accidents at construction sites. It provides a secure environment for workers and helps in catching falling debris, thereby mitigating risks associated with elevated work zones.

2. Mining Operations The mining sector leverages steel cable netting for slope stabilization and rockfall protection. The nets reinforce stability in steep terrains, reducing the likelihood of landslides and ensuring safer working conditions for miners.

3. Agriculture Farmers use steel cable netting for livestock containment and crop protection. The strong design keeps animals secure while preventing them from escaping. Additionally, it acts as a deterrent against wildlife, safeguarding crops from potential damage.

4. Sporting Facilities Many sporting venues employ steel cable netting to create safety barriers. For instance, in baseball and golf courses, netting protects spectators from foul balls and errant shots, enhancing the overall experience for attendees.

oem steel cable netting

5. Transport Infrastructure Steel cable netting is essential in maintaining the integrity of transport infrastructures, such as bridges and highways. It serves as a protective measure against falling objects, ensuring the safety of vehicles and pedestrians alike.

Benefits of OEM Steel Cable Netting

1. Customizability One of the foremost advantages of OEM steel cable netting is its customizability. Manufacturers can design nets based on specific project requirements, including dimensions, tensile strength, and mesh size. This adaptability allows industries to meet unique challenges effectively.

2. Durability Crafted from high-grade steel, OEM steel cable netting is recognized for its exceptional durability. It withstands harsh weather conditions and extreme loads, making it a reliable choice for long-term applications.

3. Ease of Installation The setup of steel cable netting is relatively straightforward, which saves time and labor costs. Many designs can be prefabricated, allowing for quick deployment on-site.

4. Cost-Effective Solution While the initial investment might be higher than traditional materials, the long lifespan and minimal maintenance of OEM steel cable netting often lead to greater cost savings in the long run.

5. Enhanced Safety Perhaps the most significant benefit is the safety aspect. By preventing accidents and injuries, steel cable netting contributes to a safer working environment, which is essential in industries where the risk of accidents is high.

Conclusion

OEM steel cable netting has established itself as a vital component in various industries, from construction and mining to agriculture and sports. Its combination of strength, durability, and customizability makes it an ideal solution for enhancing safety and efficiency. As industries continue to evolve and face new challenges, the importance of reliable materials like steel cable netting will only grow, ensuring that workers, assets, and the environment remain safeguarded. Embracing innovative materials and solutions is not just a trend; it is a necessity for achieving operational excellence in today's competitive landscape.

share

-

CE Certified Metal Fine Mesh & Screen Fabric | Top Quality

NewsAug.12,2025

-

Premium CE Certified 250 Micron Stainless Steel Mesh

NewsAug.11,2025

-

CE Certified Stainless Steel Wire Mesh for Screen Printing

NewsAug.10,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.09,2025

-

Decorative Brass Mesh: Elevate Interiors with Timeless Elegance

NewsAug.08,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Precision & Durability

NewsAug.07,2025