Oct . 17, 2024 11:17 Back to list

Custom Steel Mesh Solutions for OEM Applications and Industrial Needs

Exploring the World of OEM Steel Mesh Applications, Benefits, and Trends

In today's manufacturing landscape, the pursuit of high-quality materials has led to the increased popularity of OEM (Original Equipment Manufacturer) steel mesh. This innovative product plays a crucial role across various industries, ranging from construction to automotive, and serves multiple applications. In this article, we will delve into the characteristics, benefits, and emerging trends associated with OEM steel mesh.

Understanding OEM Steel Mesh

OEM steel mesh refers to a specialized form of steel wire mesh fabricated using specific designs or specifications provided by original equipment manufacturers. Unlike standard wire mesh, OEM steel mesh is tailored to meet the unique needs of a product or application. This customization can involve variations in wire diameter, mesh opening size, and material treatment to enhance durability and performance.

Key Applications of OEM Steel Mesh

1. Construction and Civil Engineering OEM steel mesh is widely used in the construction industry for reinforcing concrete structures. Its strength and flexibility allow it to withstand heavy loads, ensuring the integrity of buildings, bridges, and roads. From slabs to beams, steel mesh provides essential support, making it a vital component in modern construction projects.

2. Automotive Manufacturing In the automotive sector, OEM steel mesh plays a significant role in manufacturing components such as filters, heat exchangers, and grilles. The lightweight yet strong characteristics of steel mesh contribute to vehicles' overall performance and efficiency. Moreover, its ability to be molded into specific shapes allows for seamless integration into various automotive designs.

3. Agriculture Farmers employ OEM steel mesh for fencing, crop protection, and equipment storage solutions. The resistance to rust and corrosion makes steel mesh an ideal choice for outdoor applications. Additionally, its versatility allows farmers to create custom layouts that suit their specific agricultural needs.

4. Mining and Minerals In the mining industry, OEM steel mesh is essential for screening and sorting materials. Its durable construction ensures it can handle harsh conditions, contributing to increased efficiency in mineral processing.

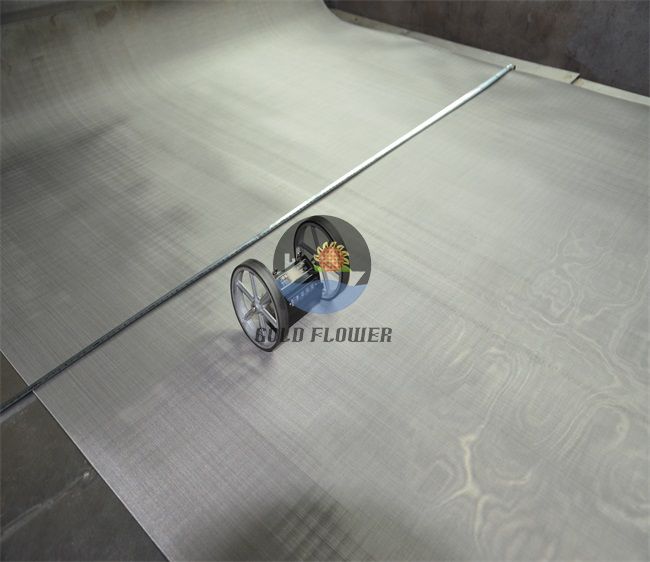

oem steel mesh

5. Architectural Design More recently, OEM steel mesh has found its way into architectural applications. Designers incorporate steel mesh into facades and interior features, appreciating its aesthetic appeal and ability to allow light penetration while maintaining privacy.

Benefits of OEM Steel Mesh

The advantages of using OEM steel mesh are manifold. First and foremost is the customized nature of production, which allows manufacturers to meet precise specifications crucial for their products. This results in enhanced performance and reliability. Additionally, steel mesh exhibits outstanding strength-to-weight ratios, making it an excellent choice for applications requiring lightweight materials without sacrificing durability.

Moreover, OEM steel mesh is highly resistant to environmental challenges, including corrosion, making it suitable for outdoor and harsh industrial environments. Its longevity translates to reduced maintenance costs and extended lifecycle, further enhancing its appeal to manufacturers.

Emerging Trends in OEM Steel Mesh

As industries continue to evolve, so do the technologies associated with OEM steel mesh. One of the most notable trends is the integration of advanced manufacturing techniques, such as 3D printing and robotic welding, which allow for even greater customization and precision. Additionally, the growing emphasis on sustainable manufacturing processes has led to increased interest in using recycled steel for OEM mesh products, reducing ecological footprints.

Another trend is the rise in smart mesh technologies. Companies are exploring ways to integrate sensors into steel mesh applications for real-time monitoring, providing valuable data for performance optimization.

Conclusion

In conclusion, OEM steel mesh is a cornerstone in various industries due to its versatility, durability, and customizability. Whether in construction, automotive, agriculture, or beyond, its applications are vast and varied, empowering manufacturers to create products that meet specific demands. With emerging trends pointing towards increased customization and sustainability, the future looks promising for OEM steel mesh, solidifying its role as an essential material in the modern manufacturing landscape. As industries continue to innovate, OEM steel mesh will undoubtedly adapt to meet their evolving needs, ensuring its relevance for years to come.

share

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025

-

Premium Stainless Steel Mosquito Mesh - Durable, Rust-Resistant Protection for Windows & Doors

NewsJul.08,2025

-

Premium Stainless Steel Garden Mesh for Lasting Durability Best & High Quality Mesh Solutions

NewsJul.07,2025

-

Gold and White Blackout Curtains – Elegant Light Blocking & Insulation for Home

NewsJul.07,2025

-

Premium Spa Filter Cartridge for Clean Water Spa Pool Filters Cartridges for Jacuzzi Durable, high-efficiency spa filter cartridge for spas and jacuzzis. Improve water quality—order your pool filter cartridge now!

NewsJul.07,2025