Nov . 06, 2024 11:38 Back to list

OEM Wire Cloth Manufacturing Solutions for Diverse Industrial Applications

The Evolution and Significance of OEM Wire Cloth Manufacturing

In today’s industrial landscape, the demand for high-quality and reliable materials has surged, making OEM (Original Equipment Manufacturer) wire cloth manufacturing an essential component across various sectors. This specialized niche focuses on the production and supply of wire cloth, which is a versatile and indispensable material used in a plethora of applications—from filtration to security solutions, and everything in between.

Understanding OEM Wire Cloth

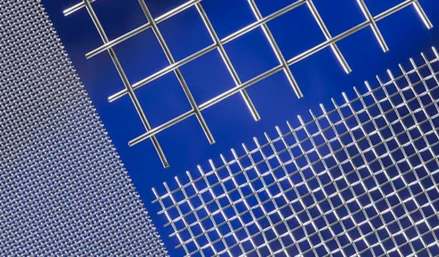

OEM wire cloth is produced in accordance with the specifications and requirements set forth by original equipment manufacturers. This means that the wire cloth is tailored to meet specific design parameters, ensuring optimal performance in the intended application. The manufacturing process involves selecting the appropriate materials, weaving techniques, and finishing processes, which can significantly impact the wire cloth's durability and functionality.

There are various types of wire cloth, including stainless steel, carbon steel, and special alloys, each offering unique chemical and physical properties. For example, stainless steel wire cloth is renowned for its corrosion resistance, making it an ideal choice for applications in harsh environments. Meanwhile, carbon steel wire cloth is favored for its strength and cost-effectiveness, often being utilized in construction and industrial settings.

Applications of OEM Wire Cloth

OEM wire cloth finds its use in a diverse range of industries. In the construction sector, it is commonly employed for reinforcing materials, providing stability and support to structures. In the aerospace industry, wire cloth is crucial for creating filters and screens that maintain the purity and safety of fuel and hydraulic systems. Additionally, applications in mining and mineral processing often rely on wire cloth for separation and classification of materials.

oem wire cloth mfg

The food and beverage industry also makes extensive use of OEM wire cloth. For instance, it is used in the design of filtration systems to ensure that products meet safety and quality standards. The ability to customize wire cloth by adjusting the mesh size, wire diameter, and material type makes it an invaluable resource in achieving specific performance criteria in these critical applications.

Quality Assurance in Manufacturing

One of the significant advantages of OEM wire cloth manufacturing is the emphasis on quality assurance. Manufacturers who specialize in this field invest in advanced technologies and methods to ensure that their products meet industry standards and client specifications. This includes rigorous testing of material properties, stress testing, and adherence to regulatory compliance. By establishing strong quality control processes, manufacturers can guarantee the consistency and reliability of their wire cloth products.

Moreover, the collaboration between manufacturers and OEMs often leads to innovations in design and functionality. As different industries evolve and demand more specialized applications, wire cloth manufacturers are continually adapting to incorporate new technologies and materials into their offerings.

Conclusion

The significance of OEM wire cloth manufacturing cannot be overstated. As industries strive for enhanced performance and efficiency, the importance of high-quality wire cloth will only continue to grow. Its versatility, coupled with the ability to customize products to meet specific needs, positions OEM wire cloth as a vital element in the manufacturing process across various fields.

As we advance further into an era driven by technology and innovation, staying abreast of developments in OEM wire cloth manufacturing will be crucial for businesses aiming to maintain competitiveness and meet the evolving demands of their markets. Thus, investing in high-quality wire cloth solutions not only serves as a foundation for operational excellence but also contributes to the overall success and sustainability of industrial operations.

share

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025

-

Premium Stainless Steel Mosquito Mesh - Durable, Rust-Resistant Protection for Windows & Doors

NewsJul.08,2025

-

Premium Stainless Steel Garden Mesh for Lasting Durability Best & High Quality Mesh Solutions

NewsJul.07,2025

-

Gold and White Blackout Curtains – Elegant Light Blocking & Insulation for Home

NewsJul.07,2025

-

Premium Spa Filter Cartridge for Clean Water Spa Pool Filters Cartridges for Jacuzzi Durable, high-efficiency spa filter cartridge for spas and jacuzzis. Improve water quality—order your pool filter cartridge now!

NewsJul.07,2025