Nov . 19, 2024 15:10 Back to list

Oil Pressure Sensor Filter for Enhanced Screen Performance and Reliability

Understanding Oil Pressure Sensor Screen Filters Importance and Maintenance

Oil pressure sensors play a crucial role in monitoring the engine’s performance and ensuring longevity. These sensors provide vital information regarding the oil pressure levels within an engine, which can be indicative of potential problems. One of the essential components associated with oil pressure sensors is the screen filter, which ensures the accurate functioning of the sensor and protects it from harmful contaminants. In this article, we will explore the significance of oil pressure sensor screen filters, their functionality, and maintenance tips to ensure optimal performance.

The Role of Oil Pressure Sensors

Oil pressure sensors are designed to measure the pressure of the oil circulating through the engine. Proper oil pressure is vital as it ensures that all engine parts receive adequate lubrication, reducing friction and preventing overheating. If oil pressure drops below a certain level, it can lead to catastrophic engine failure. The sensor communicates this critical information to the vehicle's engine control unit (ECU), which can alert the driver or take preemptive measures to prevent engine damage.

Importance of Screen Filters

Screen filters are integral to the efficient functioning of oil pressure sensors. These filters prevent dirt, debris, and other contaminants from entering the sensor, which can cause erroneous readings or damage to the sensor itself. Given the complex nature of engine components, foreign particles can easily accumulate and create issues. By filtering out these impurities, screen filters help maintain the integrity of the oil pressure sensor and, by extension, the engine.

How Screen Filters Work

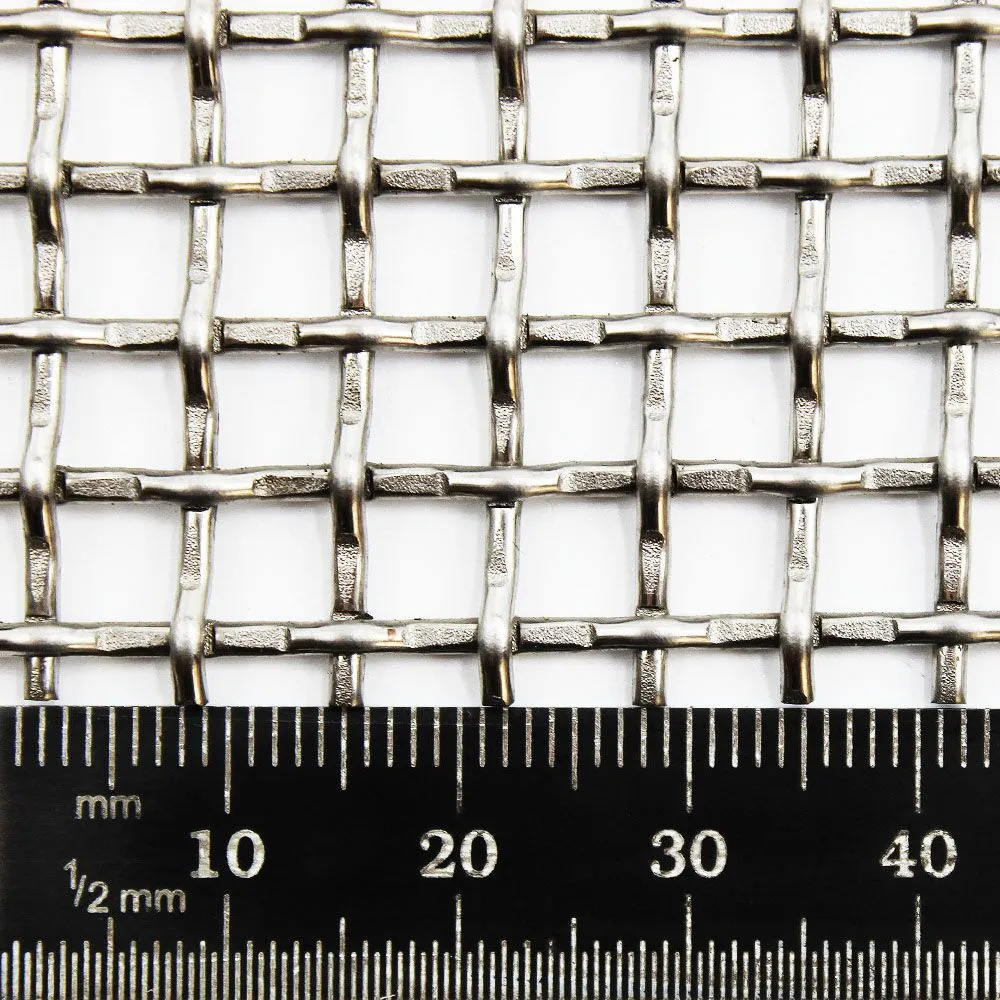

The screen filter typically consists of a fine mesh material that traps particles while allowing oil to flow through unimpeded. The construction of these filters is critical; they are designed to maintain an optimal flow rate while effectively capturing contaminants. There are different types of screen filters available, varying in size and mesh density, depending on the specific requirements of the engine and its design.

Signs of a Clogged Screen Filter

Over time, screen filters can become clogged with debris, leading to reduced oil flow and inaccurate pressure readings. There are several signs to look for that may indicate a clogged screen filter

1. Warning Lights An illuminated oil pressure warning light on the dashboard can indicate that the oil pressure is too low, which might be caused by a clogged filter.

oil pressure sensor screen filter

3. Engine Overheating Poor oil circulation can lead to overheating. If the engine temperature gauge spikes, it might be worth checking the oil pressure system, including the screen filter.

Maintenance Tips

Maintaining the oil pressure sensor and its screen filter is critical to ensuring optimal engine performance. Here are some practical maintenance tips

1. Regular Oil Changes Regular oil changes help minimize the buildup of contaminants in the oil, thereby reducing the likelihood of clogging the screen filter. Follow the manufacturer's recommendations regarding oil change intervals.

2. Inspect the Screen Filter During routine maintenance, inspect the screen filter for any signs of wear or blockage. If contaminants are found, clean or replace the filter as necessary.

3. Use Quality Oil Always use high-quality oil that meets the specifications outlined by the vehicle manufacturer. Quality oil typically contains additives that help keep the engine and its components clean.

4. Watch for Leaks Regularly inspect for oil leaks around the sensor and its connections. Leaks can lead to low oil levels, which can impair the function of the sensor and filter.

Conclusion

In conclusion, oil pressure sensor screen filters are essential for the effective performance of an engine. They protect the sensors from contaminants and ensure accurate readings, which are vital for maintaining engine health. Regular maintenance and awareness of potential issues related to oil pressure sensors will help keep your vehicle running smoothly. By paying attention to the indicators of trouble and implementing good maintenance habits, you can prolong the life of your engine and enhance its performance.

share

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025

-

CE Certification Buy Wire Mesh Fence for High Security and Durability

NewsJul.30,2025

-

Stainless Steel Mesh Filter Discs for Precise Filtration Solutions

NewsJul.29,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.29,2025

-

Premium Stainless Steel Weave Mesh for Filtration and Security

NewsJul.29,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Safety & Durability

NewsJul.29,2025