Dec . 04, 2024 13:53 Back to list

Top Stainless Steel Wire Mesh Manufacturers and Their Products

The Role of SS Wire Mesh Manufacturers in Industry

Stainless Steel (SS) wire mesh is a versatile and highly durable product used in a plethora of industries, ranging from food processing to pharmaceuticals, construction, and agriculture. The manufacture of SS wire mesh is an intricate process demanding precision, quality materials, and expertise. As industries increasingly seek reliable and efficient solutions, SS wire mesh manufacturers play a crucial role in meeting these demands.

Understanding SS Wire Mesh

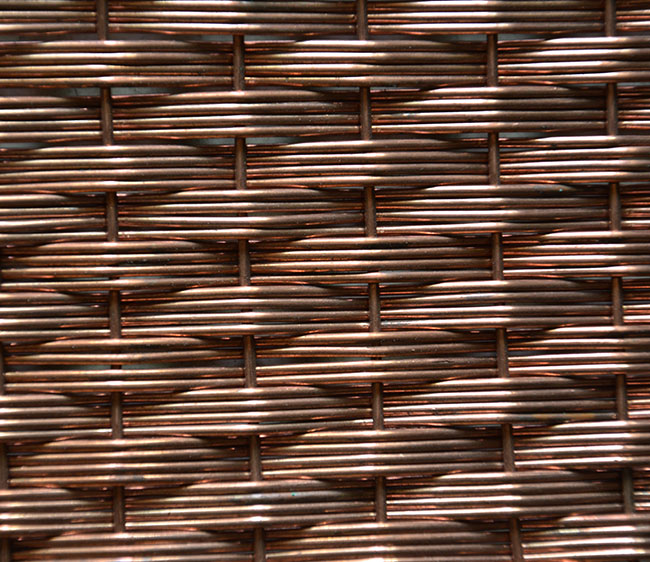

SS wire mesh is made from stainless steel, which is an alloy primarily composed of iron, carbon, and chromium. This unique composition gives stainless steel its signature resistance to rust and corrosion, making it an ideal choice for a wide variety of applications. The wire mesh itself is produced by weaving wires together into a grid-like pattern, creating spaces that can vary in size depending on the intended application. The mesh can come in various forms, including woven wire, welded wire, and expanded metal, each catering to specific needs.

Applications Across Industries

The applications of stainless steel wire mesh are diverse. In the food industry, it is commonly used in filtration systems, safety guards, and cooking utensils due to its hygienic properties. It can withstand high temperatures and is easy to clean, making it suitable for contact with food products. In the construction industry, SS wire mesh is often used as reinforcement in concrete structures, providing additional strength and stability.

Moreover, the petrochemical and pharmaceutical industries utilize stainless steel wire mesh for filtration and separation processes. Its ability to maintain its integrity in chemically aggressive environments adds to its popularity. In agriculture, SS wire mesh serves various purposes, including pest control, fencing, and crop support systems.

Quality and Standards in Manufacturing

ss wire mesh manufacturers

Given the critical nature of various applications of SS wire mesh, quality is paramount. Manufacturers must adhere to stringent standards and certifications to ensure their products meet industry regulations. ISO certifications and other quality standards are often sought by manufacturers to enhance their credibility and reliability.

The manufacturing process typically involves several stages sourcing high-quality raw materials, drawing the wire to the specified diameter, weaving or welding the wire into a mesh, treating the surface to enhance properties, and finally, cutting the mesh to meet customer specifications. Advanced machinery and technologies play a significant role in streamlining these processes, ensuring precision and consistency in every batch produced.

Customization and Innovation

An essential aspect of SS wire mesh manufacturers is their ability to offer customized solutions. Different industries have specific requirements, whether in terms of mesh size, wire diameter, or coating types. Manufacturers that can provide tailored solutions will stand out in an increasingly competitive market. Innovations such as anti-corrosion coatings and improved weaving technologies are being integrated to enhance the longevity and performance of the wire mesh.

Environmental Considerations

As industries become more environmentally conscious, SS wire mesh manufacturers are also focusing on sustainable practices. The recyclability of stainless steel makes it an eco-friendly material choice. Manufacturers are also exploring ways to reduce waste during production and limit energy consumption.

Conclusion

In conclusion, SS wire mesh manufacturers are essential players in various industries, providing durable and reliable solutions for a myriad of applications. Their commitment to quality, customization, and innovation positions them as indispensable partners in modern manufacturing processes. As industries continue to evolve and face new challenges, SS wire mesh will undoubtedly remain a vital component, showcasing the hardworking spirit and ingenuity of its manufacturers. By consistently meeting standards and adapting to changes in market demands, these manufacturers will continue to thrive in an ever-changing landscape.

share

-

Premium Stainless Steel Netting Mesh Discount & ODM Stainless Steel Wire Mesh Solutions

NewsJun.24,2025

-

High-Quality Screen Stone for Modern Stone Screen Walls Elegant Facade Solutions

NewsJun.10,2025

-

High Quality Wire Filter – Cheap Stainless Steel Filter Wire Mesh Cloth & Wire Mesh Filter Solutions

NewsJun.10,2025

-

5 Micron Water Filter Cartridge - Premium Sediment Filtration, Universal Fit

NewsJun.10,2025

-

High Quality CE-Certified Gabion Boxes with OEM Options

NewsJun.10,2025

-

20x20x2 Air Filter High-Efficiency Dust Filtration for Clean Air

NewsJun.10,2025