Jul . 26, 2024 09:18 Back to list

Stainless Steel Fabrication for CE Certification Ensuring Quality and Compliance in Manufacturing Processes

Understanding CE Certification for Stainless Steel Fabrication

In today’s global marketplace, compliance with safety and quality standards is crucial for manufacturers aiming to gain consumer trust and access international markets. One such standard is the CE marking, which is a certification that indicates a product meets the essential requirements of relevant European directives. For businesses involved in stainless steel fabrication, understanding CE certification is vital not only for legal compliance but also for ensuring the quality and safety of the products they produce.

What is CE Certification?

CE marking, derived from the French phrase Conformité Européenne, translates to European Conformity. It serves as a declaration by the manufacturer that their product meets all applicable European Union (EU) legislation. The mark is essential for products being sold in the European Economic Area (EEA), indicating that they adhere to safety, health, and environmental protection standards.

The process of obtaining CE certification involves several steps, including product testing, risk assessment, and ensuring that product documentation is in compliance with necessary directives. For stainless steel fabrication, this could involve a variety of products, such as kitchen equipment, construction materials, and industrial components.

The Importance of CE Certification in Stainless Steel Fabrication

1. Market Access CE marking is mandatory for many products sold within the EEA. Without it, manufacturers cannot legally market their products in these regions. For stainless steel fabricators, obtaining CE certification opens doors to new markets and customers, enhancing business growth.

2. Consumer Confidence CE marking signifies that products meet stringent safety and environmental standards. This builds consumer trust, as customers feel more secure in purchasing products that are certified. For instance, stainless steel kitchenware or industrial tools with a CE mark convey that they are made to comply with high-quality standards.

3. Legal Compliance The EU has a comprehensive framework for product safety that requires compliance from manufacturers. Failure to obtain CE certification can lead to legal repercussions, including fines, product recalls, and damage to a company’s reputation. Ensuring compliance helps mitigate these risks.

4. Quality Assurance The CE certification process involves thorough testing and evaluation. This implies that products undergo rigorous quality assurance checks, ensuring that they perform as intended and meet customer expectations. This is particularly important in stainless steel fabrication, where the quality of materials significantly impacts durability and performance.

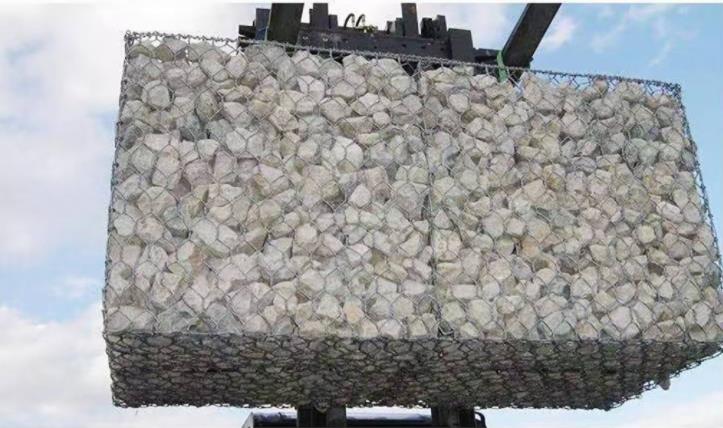

ce certification stainless steel fabric

5. Competitive Advantage In a crowded market, having CE certification can set a company apart from competitors. It demonstrates a commitment to quality and safety, which can be a deciding factor for buyers when choosing between different manufacturers.

Steps to Achieve CE Certification

To obtain CE certification for stainless steel fabricated products, manufacturers should

1. Identify Applicable Directives Determine which EU directives apply to the product. For stainless steel products, directives such as the Low Voltage Directive or the Machinery Directive may be relevant.

2. Conduct Risk Assessment Evaluate potential risks associated with the product and determine how to mitigate them effectively.

3. Testing and Evaluation Engage accredited testing facilities to ensure that products meet the essential safety and performance requirements.

4. Documentation Prepare and maintain technical documentation that demonstrates compliance, including design calculations, test reports, and declarations of conformity.

5. Affix the CE Mark Once compliance is confirmed, manufacturers can affix the CE mark to their products and prepare for market entry.

Conclusion

In conclusion, CE certification is not just a regulatory requirement but a strategic advantage for companies involved in stainless steel fabrication. By adhering to these standards, manufacturers can ensure product safety, legal compliance, and enhanced marketability. As global trade expands, understanding and implementing CE certification processes will become increasingly pivotal for success in the steel fabrication industry.

share

-

CE Certified 250 Micron SS Mesh: Precision & Durability

NewsAug.15,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.14,2025

-

Precision CE Certified 250 Micron Stainless Steel Mesh

NewsAug.13,2025

-

CE Certified Metal Fine Mesh & Screen Fabric | Top Quality

NewsAug.12,2025

-

Premium CE Certified 250 Micron Stainless Steel Mesh

NewsAug.11,2025

-

CE Certified Stainless Steel Wire Mesh for Screen Printing

NewsAug.10,2025