Jul . 28, 2024 09:06 Back to list

Top Quality Construction Wire Mesh Options for Your Building Needs and Projects

The Importance of Choosing the Best Construction Wire Mesh

Wire mesh, a versatile material composed of interwoven wires, plays an essential role in the construction industry. It serves as a foundational element used in a variety of applications, from reinforcing concrete to creating protective barriers. Given its critical applications, selecting the best construction wire mesh is paramount to ensuring structural integrity and longevity.

Understanding Wire Mesh Types

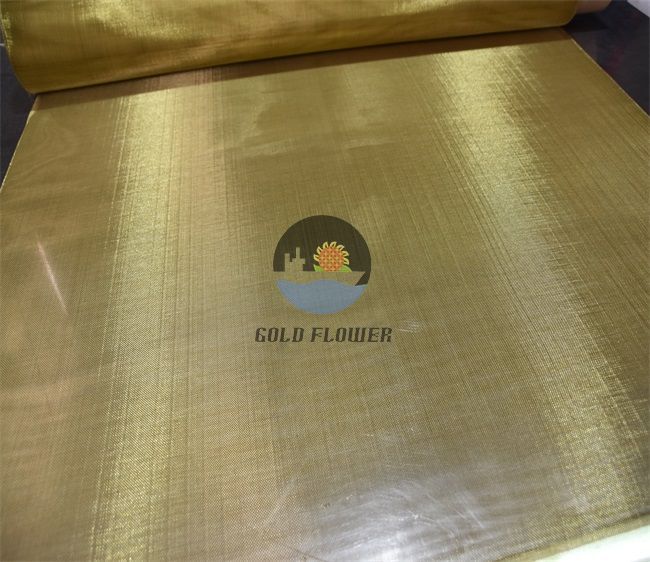

The types of wire mesh vary widely, each suited for specific applications. Common types include welded wire mesh, woven wire mesh, and expanded metal mesh. Welded wire mesh is primarily used in concrete reinforcement due to its strength and stability. The individual wires are welded together at intersections, creating a robust grid that distributes loads evenly, thereby preventing structural failures. Woven wire mesh, on the other hand, is frequently used for screening applications and is available in various gauges and openings to suit different needs. Expanded metal mesh offers a unique design with its diamond-shaped openings, making it ideal for safety and security purposes, such as fencing or stair treads.

Applications in Construction

In construction, wire mesh is utilized in various forms to enhance durability and safety. For instance, in concrete structures, wire mesh reinforcement is often embedded within the mix to bolster tensile strength, thus preventing cracks and increasing the lifespan of buildings and infrastructures. Additionally, wire mesh can be employed in fences and barriers surrounding construction sites, providing safety and security.

Moreover, wire mesh is an integral part of road construction. It fortifies asphalt layers by helping to distribute heavy loads effectively, thus reducing wear and tear. In such applications, choosing high-quality wire mesh made from corrosion-resistant materials is crucial, as this ensures longevity even in harsh environmental conditions.

Factors to Consider When Choosing Wire Mesh

best construction wire mesh

When selecting the best construction wire mesh, several key factors should be considered

1. Material Quality The durability and effectiveness of wire mesh are significantly influenced by the materials used. Stainless steel or galvanized steel wire mesh is often preferred for its resistance to corrosion and rust, especially in outdoor or moist environments.

2. Mesh Size and Configuration The size of the openings in the wire mesh should be carefully chosen based on the intended application. For instance, smaller openings may be necessary for applications requiring more support, while larger openings may suffice for screening or fencing purposes.

3. Gauge Thickness The thickness of the wire also plays a crucial role in the strength and weight-bearing capacity of the mesh. Thicker wires generally provide more robustness, although they may also increase costs.

4. Standards and Certifications Always check for industry standards and certifications when purchasing wire mesh. Stringent quality control and compliance with safety regulations are essential to guarantee that the wire mesh will perform effectively in construction applications.

5. Supplier Reputation Opting for a reputable supplier can make a significant difference. Established companies often provide better quality products, technical support, and warranty guarantees, ensuring peace of mind.

Conclusion

In conclusion, construction wire mesh is a vital element in the building industry, influencing the safety, durability, and effectiveness of various applications. Whether for reinforcing concrete structures, providing security, or improving road quality, the importance of choosing high-quality wire mesh cannot be overstated. By considering factors such as material quality, mesh size, and the reputation of the supplier, builders and contractors can ensure that they select the best construction wire mesh for their projects, ultimately contributing to the safety and reliability of their constructions.

share

-

CE Certified 250 Micron SS Mesh: Precision & Durability

NewsAug.15,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.14,2025

-

Precision CE Certified 250 Micron Stainless Steel Mesh

NewsAug.13,2025

-

CE Certified Metal Fine Mesh & Screen Fabric | Top Quality

NewsAug.12,2025

-

Premium CE Certified 250 Micron Stainless Steel Mesh

NewsAug.11,2025

-

CE Certified Stainless Steel Wire Mesh for Screen Printing

NewsAug.10,2025