May . 23, 2025 16:11 Back to list

Unlock the Durability and Efficiency of Copper Mesh Screen for Various Applications

When it comes to high-quality filtration and effective separation, copper mesh screen stands out as a versatile and reliable option. Known for its excellent conductivity, resistance to corrosion, and overall durability, copper screen is widely used in industries ranging from filtration to decorative applications. Whether you're considering it for its aesthetic appeal or practical utility, understanding the properties of copper wire mesh screen and copper fly screen mesh can help you make an informed decision for your next project.

What is Copper Mesh Screen?

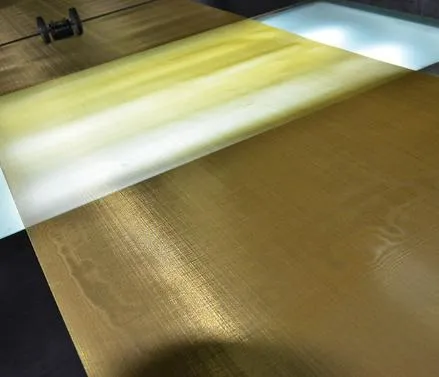

A copper mesh screen is a woven or welded metal mesh made from pure copper wires. It features an intricate interlaced pattern that gives it both flexibility and strength. Copper screen is commonly used in applications that require fine filtration, separation, or protection from dust, insects, and other particulate matter. Its natural properties, including its resistance to corrosion and excellent electrical conductivity, make it highly valuable in various sectors, from industrial processes to home uses.

The distinctive characteristics of copper wire mesh screen make it an ideal choice for environments where the mesh needs to endure exposure to moisture and various chemicals. This mesh can come in various forms—woven, welded, or knitted—depending on its specific use. For example, copper fly screen mesh is specifically designed for protecting spaces from insects without blocking airflow, making it popular in homes and businesses alike.

The Influence of Copper Mesh Screen Thickness on Durability

One of the key factors that influence the performance and lifespan of a copper mesh screen is its thickness. Thicker copper screen options tend to offer enhanced durability, which makes them ideal for more demanding applications. The thickness of the copper wires used in the mesh directly impacts its tensile strength, flexibility, and ability to withstand external forces like pressure, abrasion, and even environmental wear.

Thicker copper wire mesh screen is more resistant to physical damage and corrosion, ensuring a longer lifespan even in harsh conditions. It is also less likely to deform under stress, making it an excellent choice for industrial filtration systems or outdoor uses where it may be exposed to wind, rain, or other environmental stressors. For residential uses, such as copper fly screen mesh, a thinner version might be used to allow for better air circulation while still providing adequate protection against pests.

Choosing the right thickness is essential when selecting a copper mesh screen for your project. For high-strength applications, thicker mesh may be required, whereas for more decorative or light-duty purposes, thinner options may suffice. No matter the thickness, you can always rely on the inherent durability of copper, which ensures that the mesh will perform effectively for years.

Copper Mesh Screen: The Difference in Filtration Accuracy of Copper Meshes with Different Mesh Sizes

The mesh size of a copper wire mesh screen plays a critical role in its filtration accuracy. Mesh size refers to the number of holes in the screen per inch, and it directly affects how fine the filtration will be. Finer mesh sizes, such as those with higher mesh counts (e.g., 200 mesh), provide more precise filtration, able to trap smaller particles and debris. In contrast, coarser mesh sizes (e.g., 10 mesh) allow larger particles to pass through, making them suitable for applications requiring less precise filtration.

For industries that require high-precision filtering, such as pharmaceuticals or food processing, selecting the correct mesh size in copper screen is crucial. A finer mesh ensures that only the desired substances pass through, improving the efficiency of the filtration process. On the other hand, for applications like construction or gardening, where larger debris needs to be filtered out, a coarser mesh might be a better fit.

In applications such as copper fly screen mesh, where the goal is to keep insects out while allowing air circulation, a medium mesh size offers the perfect balance. It provides effective insect protection without sacrificing airflow or light transmission, making it ideal for windows, doors, and outdoor spaces.

Applications of Copper Mesh Screen in Various Industries

Beyond its role in filtration, copper mesh screen is also used in a wide range of industries, including construction, electronics, and interior design. Its natural anti-microbial properties make it particularly useful in environments where cleanliness and hygiene are paramount, such as hospitals, laboratories, or food processing plants.

In the electronics industry, copper screen is used for electromagnetic interference (EMI) shielding. By using a tightly woven mesh, it helps protect sensitive equipment from electromagnetic radiation, preventing signal distortion and ensuring the longevity of electronic devices.

In construction, copper wire mesh screen serves as a protective barrier, particularly in areas that require added strength and security. It is used in security fencing, in reinforcement for concrete, and as a decorative element in architecture. The aesthetic appeal of copper fly screen mesh also makes it a popular choice for both functional and decorative applications in home design, such as in the creation of custom window screens.

How to Select a High-Quality Copper Mesh Screen for Your Needs

Selecting a high-quality copper mesh screen involves considering factors like wire thickness, mesh size, and the specific application for which the mesh will be used. Start by identifying the requirements of your project—whether it’s for filtration, protection, or decoration. For example, in an industrial setting where durability is paramount, opt for thicker copper wire mesh. If you're using it for aesthetic purposes, such as in architectural design, consider the visual appeal and how the copper will patina over time.

Additionally, the quality of the copper used in the screen is vital. Pure copper provides the best conductivity and corrosion resistance, but for certain applications, you might find that alloyed copper meshes provide better mechanical properties. Always choose copper screen from reputable manufacturers and suppliers who offer high-grade materials and expert guidance to help you make the right choice.

Copper Mesh Screen FAQs

What is the best application for copper mesh screen?

Copper mesh screen is highly versatile and can be used in filtration, decoration, and electromagnetic shielding. It is ideal for industries such as pharmaceuticals, food processing, electronics, and construction.

How does the thickness of copper screen affect its performance?

Thicker copper screen offers better durability and resistance to corrosion and physical damage. It is suitable for heavy-duty applications requiring strength, such as industrial filtration or outdoor protective barriers.

What is the impact of mesh size on filtration?

The mesh size determines the filtration accuracy. Finer mesh screens filter out smaller particles, while coarser meshes are more suited for larger debris. Choose the mesh size based on the specific filtration needs of your project.

Is copper fly screen mesh suitable for outdoor use?

Yes, copper fly screen mesh is perfect for outdoor applications. It offers excellent protection against insects while allowing for airflow and light, making it ideal for windows, doors, and porches.

How can I select the right copper wire mesh screen for my project?

Consider factors like mesh size, thickness, and material quality. For precise filtration, choose a fine mesh, while for more robust applications, a thicker mesh with larger openings may be more appropriate.

share

-

What Factors Influence Gabion Mesh Price and Sizing?

NewsJun.23,2025

-

What Factors Impact the Selection and Cost of Gabion Products?

NewsJun.23,2025

-

What Are the Key Uses and Considerations for Gabion Products?

NewsJun.23,2025

-

What Are the Key Applications and Benefits of Welded Mesh Gabion Baskets and Related Solutions?

NewsJun.23,2025

-

What Are the Key Applications and Benefits of Gabion Solutions?

NewsJun.23,2025

-

What Are the Key Applications and Advantages of Welded Wire Gabion Baskets and Related Solutions?

NewsJun.23,2025