Mar . 19, 2024 11:52 Back to list

What is wire mesh? Definition, features, and target markets

A great variety of shapes and applications

“Wire mesh” is a generic term. It refers to two- or three-dimensional lattices made from two or more metallic wires which are linked to one another by different processes such as welding, weaving, netting, or knitting. Wire mesh products are widely employed for reinforcing, armoring, protecting, fencing, carrying, and displaying operations in a large variety of areas. Therefore, we can say that wire mesh is an integral part of industry and everyday life.

Wire mesh materials and their main characteristics

Wires used for wire mesh can be made from carbon steel, galvanized steel, PVC coated steel, stainless steel, aluminum, copper, copper alloys (brass and bronze), and other metals or alloys. Let’s take a look at the differences between all of these materials.

Mesh made of carbon steel wires has high strength, is magnetic, and can be galvanized or cladded with a PVC coating or painted to prevent corrosion. Mesh made from stainless steel wires, instead, does not require further surface treatment. While on the one hand, copper wire is ductile, has a high thermal and electrical conductivity, and is resistant to atmospheric corrosion; on the other, brass wire has excellent abrasion-resistance properties. Last but not least, bronze wire is effective against atmospheric agents, while aluminum wire can be used to fabricate extremely lightweight and corrosion-resistant mesh.

The material selection, the wire diameter, and the manufacturing method depend on the application of the mesh products and their conditions of use.

Welded wire mesh

Welded wire mesh is a metal wire screen usually made out of two low carbon steel wires or stainless steel wires which are joined to each other at right angles and welded at the crossing points. Typical examples are reinforcement meshes for concrete components. In addition, there are industrial meshes in light or heavy design that can be used as fences, partition walls, and protective gratings.

Three-dimensional welded wire meshes are used e.g. as shopping carts, shopping baskets, and goods displays in supermarkets, as well as trays for domestic appliances, ventilation grids, cable guides, and cages for animals. Another example are electro-welded gabions, which are intended to hold masses of stone together and are enjoying growing popularity in landscaping.

Welded wire mesh is characterized by high stability and rigidity, and can also be welded into frame constructions.

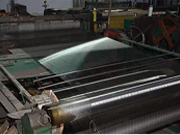

Wire fabrics

Wire fabrics, also called woven wire cloth, are flat structures made of two wire systems intersected by weaving.

Typical products are airbag filters and other reinforcement fabrics, transportation and process belts, sieves, as well as pulp and paper processing systems. Wire fabrics are also used in filtration, separation, and cleaning processes for the mining, petrochemical, pharmaceutical, and food processing industries. Furthermore, wire fabrics act as a radio and microwave shielding, spark protection, or as fly nets.

Last but not least, woven wire cloth is applied in architectural applications such as façade covering. Depending on the material of the wires and the wire cloth texture, wire fabrics can be as soft and flexible as silk, or as rigid and durable as a steel plate.

Wire nettings

Wire nettings include the so-called wire netting fences. Examples are the rectangular nettings which are often used to enclose properties. Hexagonal nettings are used in agriculture and forestry to enclose woodland plantations and protect them against animals. Such kind of netting also serves as a slope reinforcement and protection against rock slides and avalanches.

There is also a special group of nettings, that is round braids, which act as a reinforcement of hoses and cables or as shielding of cables against electromagnetic interferences.

Literature

About textile weaving:

Valeriy Choogin, Palitha Bandara, Elena Chepelyuk: Mechanisms of Flat Weaving Technology. 1st Edition. Woodhead Publishing, 2013

ISBN: 9780857097804

eBook ISBN: 9780857097859

Introduction Top Weaving Technology.

https://textilelibrary.wordpress.com/2011/04/09/introduction-to-weaving-technology/

Emel Önder, Ömer Berk Berkalp: Weaving Technology II

https://web.itu.edu.tr/~berkalpo/Weaving_Lecture/Weaving_Chapter1a_06S.pdf

Nigel Scotchmer: The Other Resistance Process: Cross Wire Welding. In: Welding Journal, December 2007, pages 36-39.

https://www.researchgate.net/publication/

For helping us compile the information, we thank Dipl.-Ing. Konrad Dengler, technical journalist and translator specialized in industrial topics.

share

-

CE Certified 250 Micron SS Mesh: Precision & Durability

NewsAug.15,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.14,2025

-

Precision CE Certified 250 Micron Stainless Steel Mesh

NewsAug.13,2025

-

CE Certified Metal Fine Mesh & Screen Fabric | Top Quality

NewsAug.12,2025

-

Premium CE Certified 250 Micron Stainless Steel Mesh

NewsAug.11,2025

-

CE Certified Stainless Steel Wire Mesh for Screen Printing

NewsAug.10,2025