Mar . 19, 2024 12:15 Back to list

What Types of Wire Mesh Are Available

There are many different wire mesh sizes, materials and types available, creating an array of applications. Here’s a closer look at the variety of wire mesh available.

Depending on the application, there are different materials best suited for the job. For example, among the most common in industrial applications is stainless steel woven wire mesh. T-304 stainless steel is the reliable standard for many industrial applications. It is known for its strength, affordability and resilient characteristics, including:

- — Corrosion resistance in multiple manufacturing environments

- — Heat resistance

- — Oxidation resistance

- — Applicability for welding using the most common techniques

- — Virtual lack of magnetivity (in an annealed condition)

Other available materials for woven wire mesh include:

- — Aluminum

- — Brass

- — Bronze

- — Copper

- — Galvanized

- — Monel

- — Steel — Carbon

- — Steel — Plain

The right wire mesh provider can easily offer you wire mesh in any metal or alloy needed.

Wire Mesh Size

Typically, wire mesh comes in 100-foot rolls and standard widths are 36″, 40″, 48″ and 60″.

Wire Mesh Weave

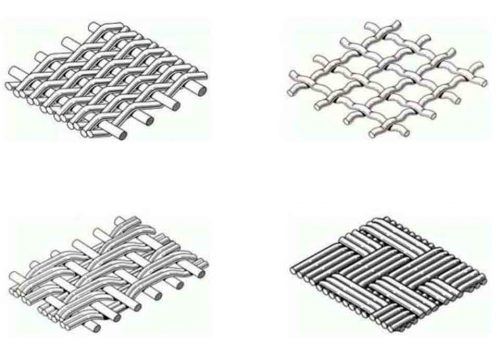

Different industrial and commercial applications require different weave types. At Newark Wire, we offer the following high-quality weave options:

- — Plain Weave. The majority of manufactured wire mesh cloth uses a plain weave. Warp wires (running the length of the wire roll) and shute wires (running the width) pass over and under each other in both directions. The weave itself locks the wires in place at the desired size

- — Intermediate Crimp Weave. In these style of mesh products, both the warp and shute wires are crimped prior to the mesh being woven, leaving extra crimps between the intersection points. It’s typically used to coarser meshes using lighter wires and assures proper locking of the wires and additional rigidity.

- — Lock Crimp Weave. Used for more rigid wire mesh applications, the lock crimp applies the crimp over the intersecting wires. The wires between the intersections are straight

- — Twilled Weave. While a plain weave has wires woven over and under each other consecutively (one over, one under), the twilled weave uses a two over, two under approach. This creates a more pliable wire mesh cloth that is commonly found in filtration applications.

In addition to these specifications, customers can choose the opening sizes, edge finishing and grade type (standard or market, bolting or milling), the latter of which refers to the wire diameter, opening size and percentage of open area

To summarize the information above, woven wire mesh:

- — Can be used in a wide range of industrial and commercial uses

- — Can be made of stainless steel or various other metals and alloys

- — Comes in a number of different weave and crimp types

share

-

CE Certified 250 Micron SS Mesh: Precision & Durability

NewsAug.15,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.14,2025

-

Precision CE Certified 250 Micron Stainless Steel Mesh

NewsAug.13,2025

-

CE Certified Metal Fine Mesh & Screen Fabric | Top Quality

NewsAug.12,2025

-

Premium CE Certified 250 Micron Stainless Steel Mesh

NewsAug.11,2025

-

CE Certified Stainless Steel Wire Mesh for Screen Printing

NewsAug.10,2025