Mar . 19, 2024 15:35 Back to list

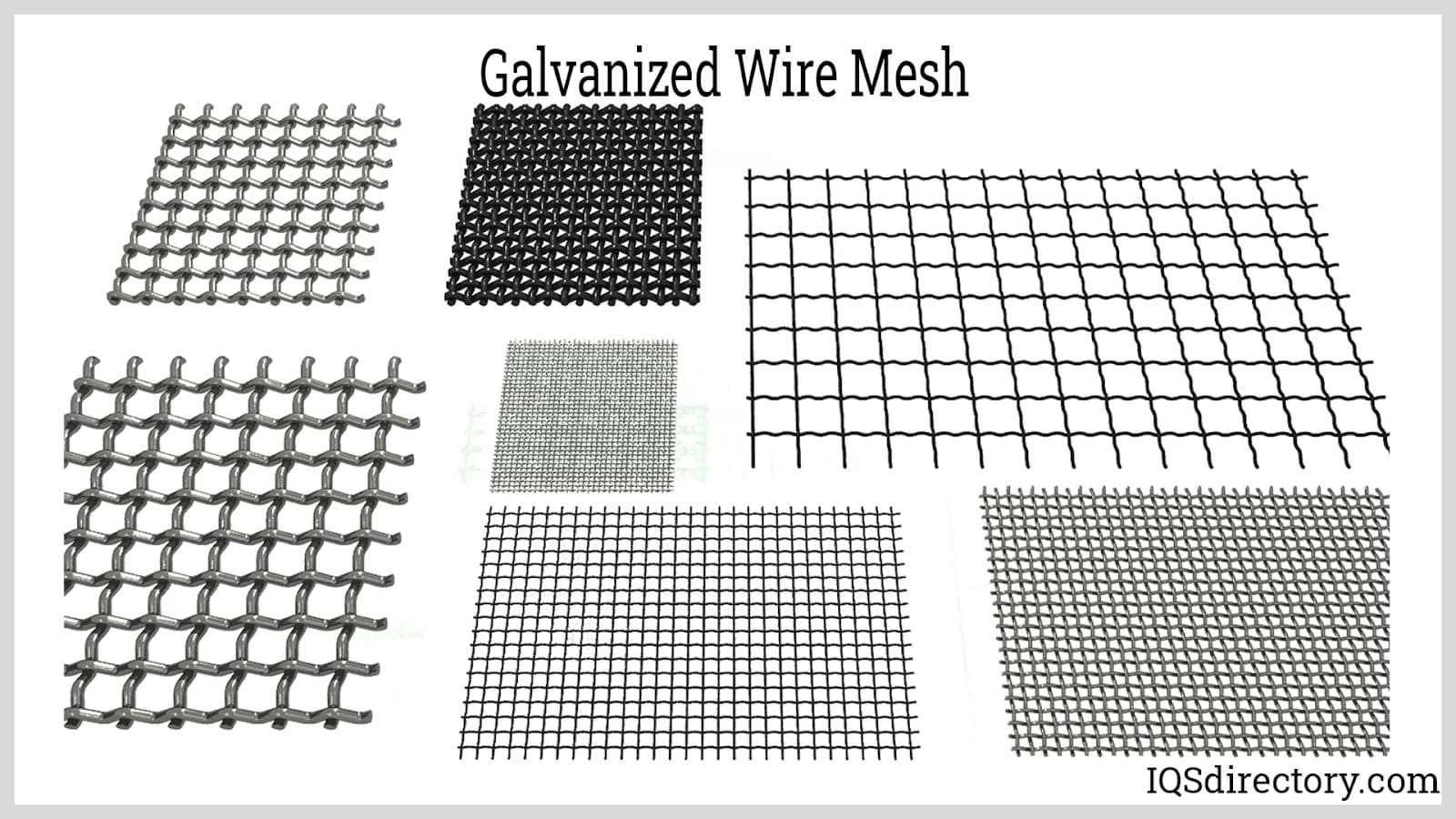

Galvanized Wire Mesh

Galvanized wire mesh is made from plain or carbon steel wire that is galvanized, a process that involves applying a zinc coating. The zinc layer acts as a shield that protects the wire mesh against rust and corrosion. Galvanized wire mesh can be welded or woven using galvanized wire or plain steel wire that is galvanized after being woven or welded. Of the two processes, galvanizing the wire mesh after it is processed initially costs more but produces a higher-quality wire mesh.

Galvanized wire mesh is ideal for fencing for agriculture and gardening, greenhouse, architecture, building and construction, security, window guards, and infill panels. Due to its cost, it is one of the more widely used of the different types of wire mesh.

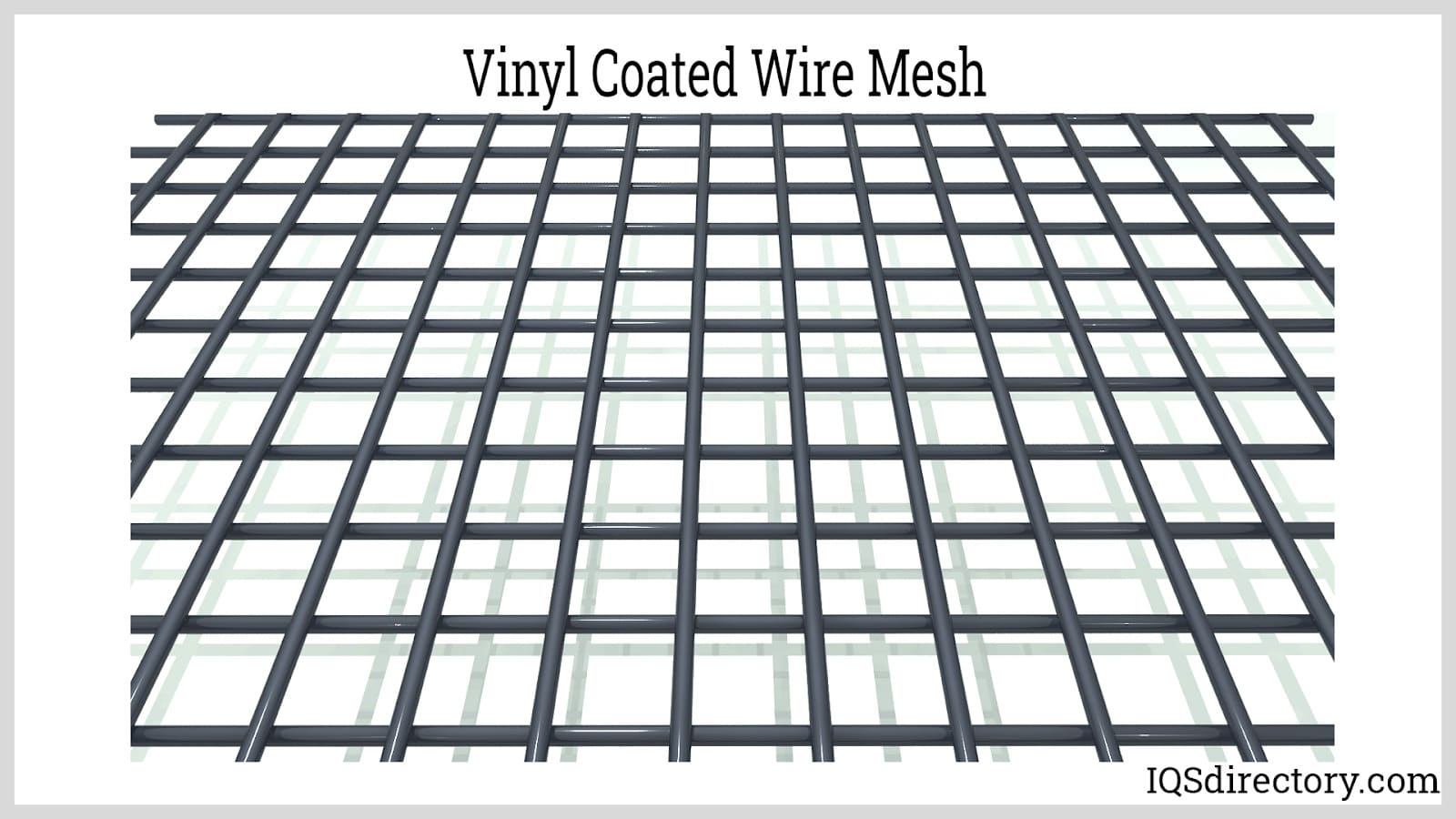

Vinyl-Coated Wire Mesh

The application of a vinyl coating to welded or woven wire mesh creates a strong barrier for very flexible wire mesh. Vinyl-coated wire mesh is stable over a wide range of temperatures, is not degraded by exposure to the sun, and is resistant to scrapes, abrasions, and impact.

The vinyl coating of wire mesh gives the impression that the mesh is made of plastic and is sometimes referred to as plastic mesh. Aside from giving wire mesh an appealing appearance, vinyl-coated wire mesh is long-lasting, durable, and rust- and corrosion-resistant. It seals the wires from water and other intrusive elements.

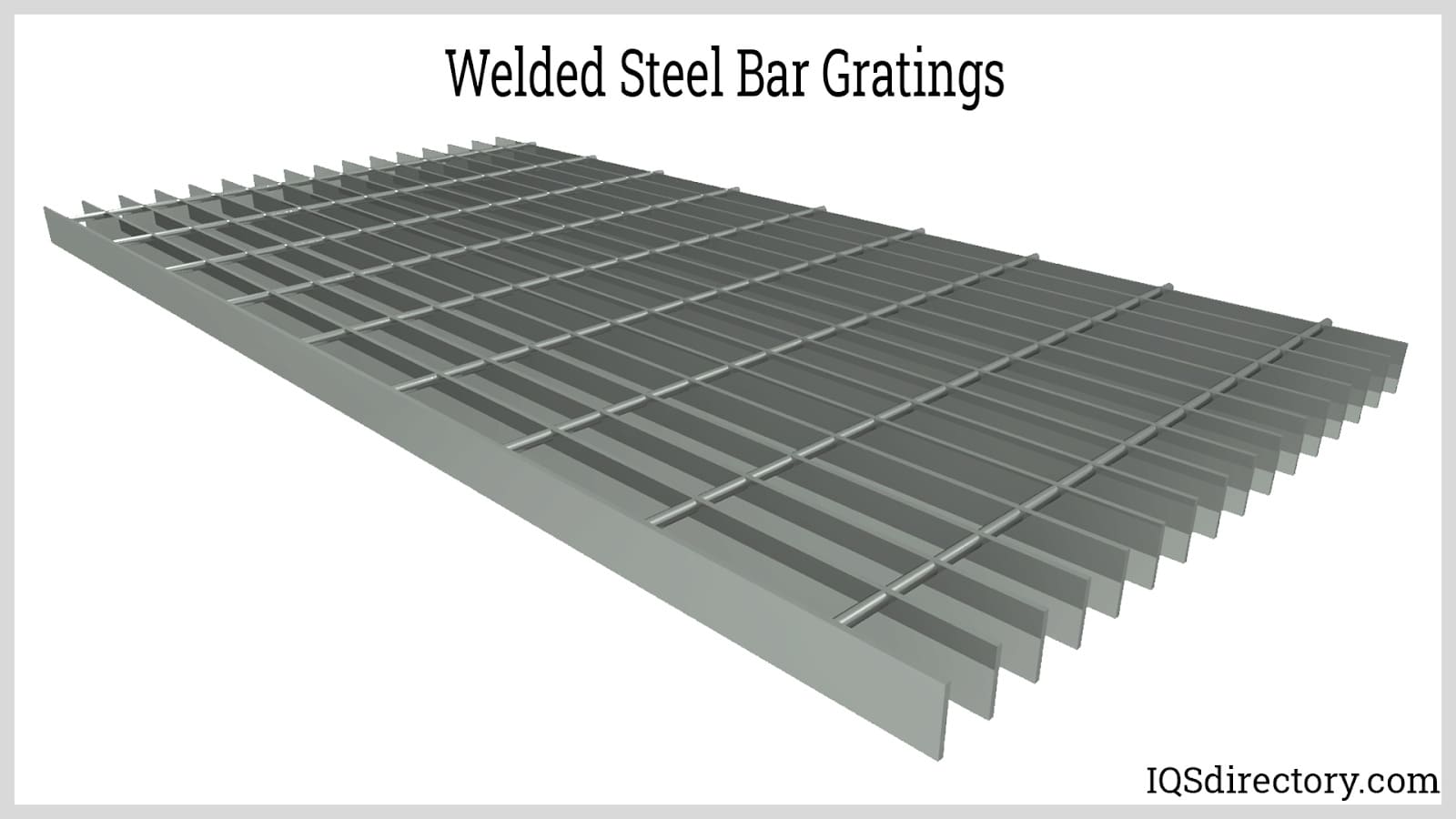

Welded Steel Bar Gratings

Welded steel bar gratings are produced by forge welding at extremely high temperatures. In this process, perpendicular bars are drawn across a parallel series of rectangular bars, connecting the bars together. The process creates a fused, long-lasting connection that can withstand the most demanding and hazardous conditions. The steel for welded steel bar gratings is carbon steel or stainless steel and is exceptionally durable, strong, and rigid.

Designed to carry heavy workloads for many years, welded steel bar grating is used for landing mats, bridge decking, ventilation grills, ramps, sidewalks, and industrial flooring. Panels are produced in two to three-foot widths in two-foot lengths in a wide range of bar sizes, from 1” to 6” depths and 0.25” up to 0.50” thicknesses.

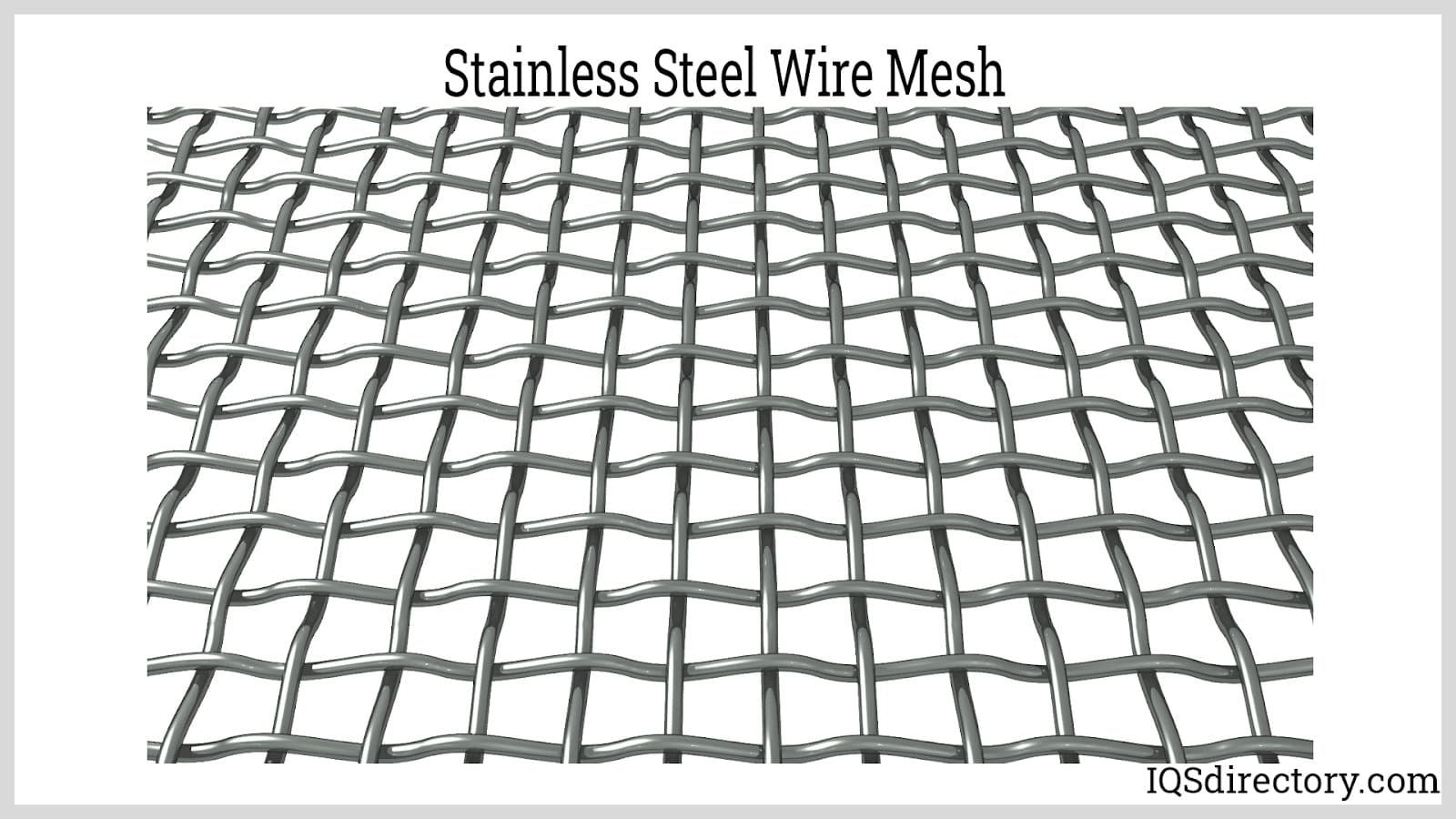

Stainless Steel Wire Mesh

Stainless steel wire mesh has all of the positive properties of stainless steel and provides high-quality protection and performance. Steel is widely used to produce wire mesh but rusts easily when exposed to the air. Stainless steel, which has the same compounds as steel, has chromium added that is rust-resistant and protects stainless steel from oxidation.

In wire mesh manufacturing, stainless steel is known for its reliability, sturdiness, and durability. The rust resistance of stainless steel makes it adaptable to any outdoor application. It consistently delivers strength and longevity, making it the most popular wire mesh form.

As with all forms of wire mesh, stainless steel can be welded or woven. The grades of stainless steel used to produce wire mesh are 304, 304L, 316, 316L, 321, 347, or 430 in wire diameters ranging from 0.0085 inch (0.216 mm) up to 0.307 inch (7.8 mm). The openings of wire mesh change in accordance with the type of wire mesh. Openings that are less than 0.25 inch (6.35 mm) are classified as wire cloth. Critical factors for wire mesh are the percent of the open area and the weight of the mesh.

Grade 316 stainless steel is a premium alloy that is used for marine applications. It has exceptional corrosion resistance and is not affected by acids, salt water, or seawater, and comes in fine, medium, or coarse sizes. Stainless steel grade 304 is not as corrosion resistant as grade 316 but is exceptionally workable and less expensive than grade 316.

Wire Mesh Patterns

The pattern of wire mesh determines its capacity and how it can be used. There are an endless number of standard weave patterns and customized ones designed to fit a specific application. One distinction between the various patterns is whether the wire is crimped or not crimped, with crimping mechanically changing the contour of the weft or warp wires.

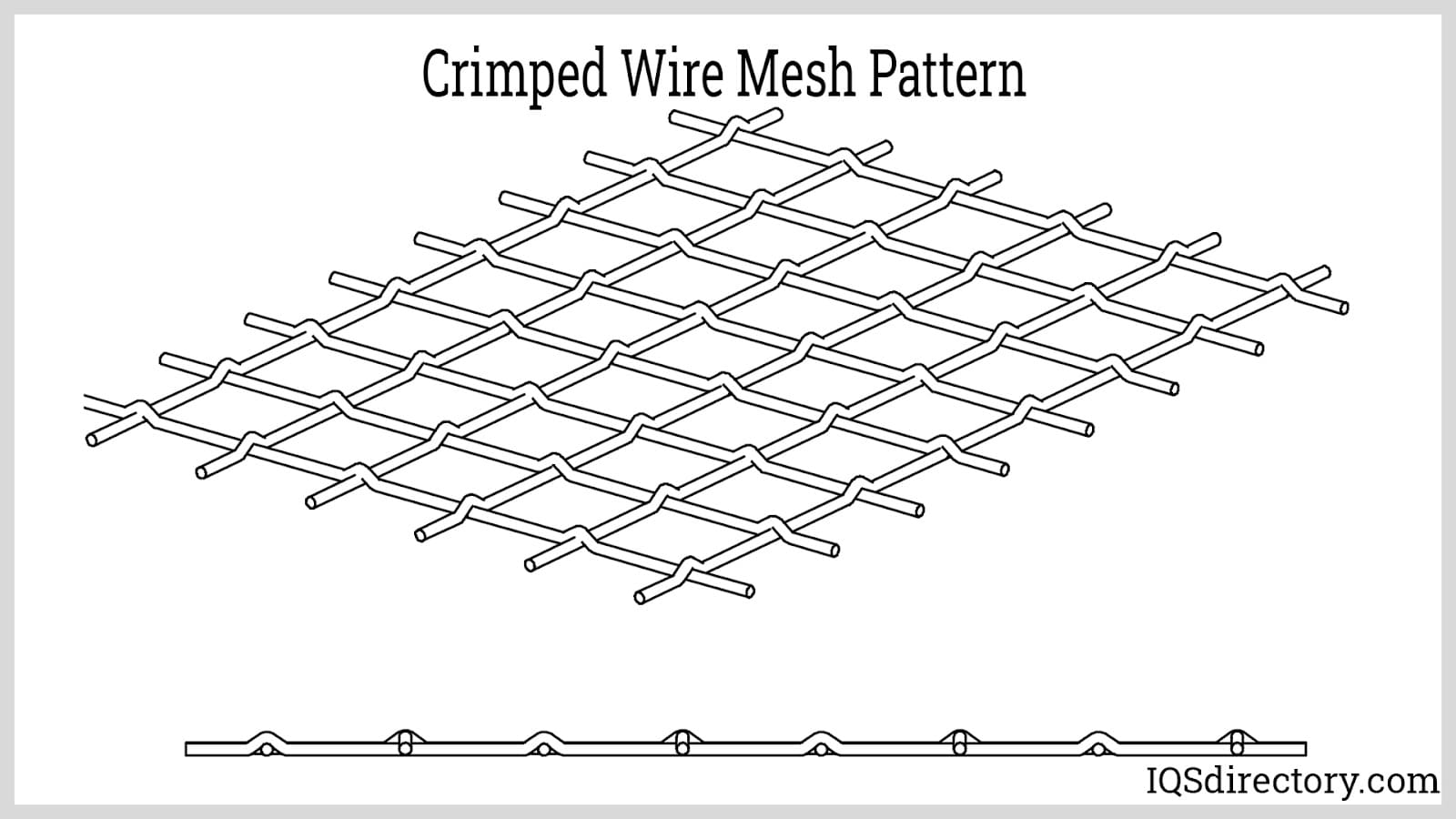

Crimped Wire Mesh

Crimped wire mesh is a square or rectangular weave that is woven using a crimping mesh machine. The processes used to produce crimped wire mesh involve compressing the wire such that the weft wire wraps over the warp wire and the warp wire wraps over the weft wire. The crimping process produces a bending effect on the wires such that they wrap over each other.

- Pre-Crimp — Pre-crimped weaves are crimped with small folds or ridges that are added before the wire is woven to increase the strength and rigidity of the wire mesh. The process prevents the weft and warp wires from moving and keeps them secure.

- Lock Crimp — Lock crimp is another pre-crimp process that uses the grooves from the crimping process to lock the weave together at the intersections of the weft and warp wires. As with pre-crimping, the final weave is sturdier and immovable.

- Inter-Crimp — With inter-crimp, the warp and weft wires are crimped with additional crimps added between the intersections. It is a process used with fine wire with large openings to ensure the weft and warp wires are accurately and properly locked to provide additional rigidity.

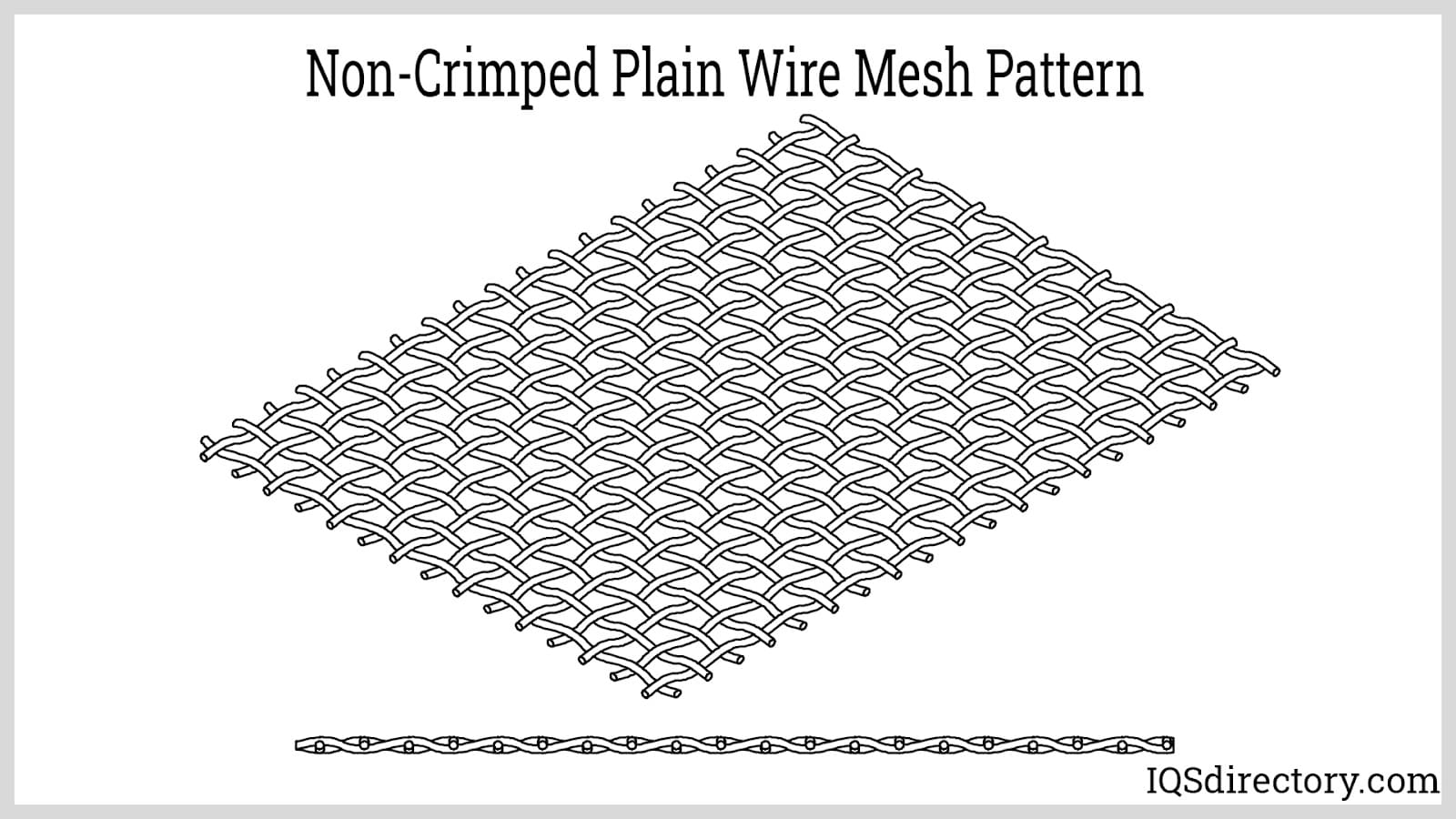

Non-Crimped Wire

Non-crimped wire refers to plain wire mesh where the wire mesh is formed by a simple over-under weave of the warp and weft wires. The final product has a simple appearance with a smooth, even surface. Traditionally, non-crimped wire or plain wire has a higher mesh count.

Plain weave wire mesh is the most common of the wire mesh products. Wire mesh that has a 3 x 3 or finer wave has a plain weave pattern. It is commonly used for screening, such as screen doors and window screens.

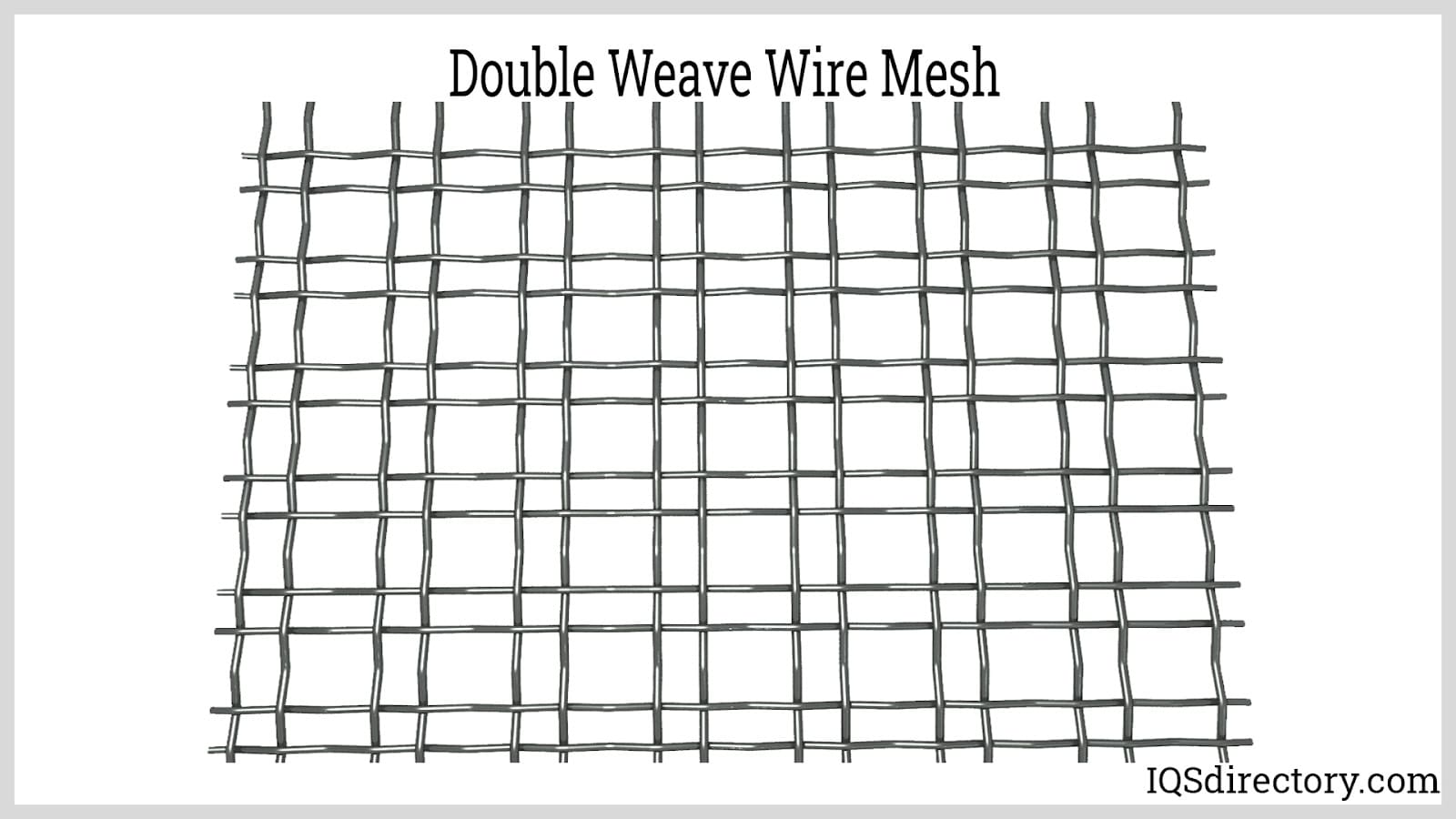

Double Weave Wire Mesh

Double weave wire mesh is a variation of the pre-crimped weave pattern. In the weaving process, the warp wires pass over and under two weft wires to form a wire mesh pattern capable of withstanding stressful and demanding uses. The double weave wire mesh pattern produces a wire mesh with extra durability for supporting vibrating screens in mining operations and crushers, fences for farming, and screens for barbecue pits.

Flat Top Weave Wire Mesh

Flat top weave has non-crimped warp wires and crimped weft wires that create a sturdy, lockable wire mesh with a flat surface. It has a long abrasive life since no wires project from the top of the mesh to wear. Flat top weave wire mesh has little flow resistance, making it popular for architectural and structural applications requiring a smooth surface. A common application for flat top weaves is for vibrating screens.

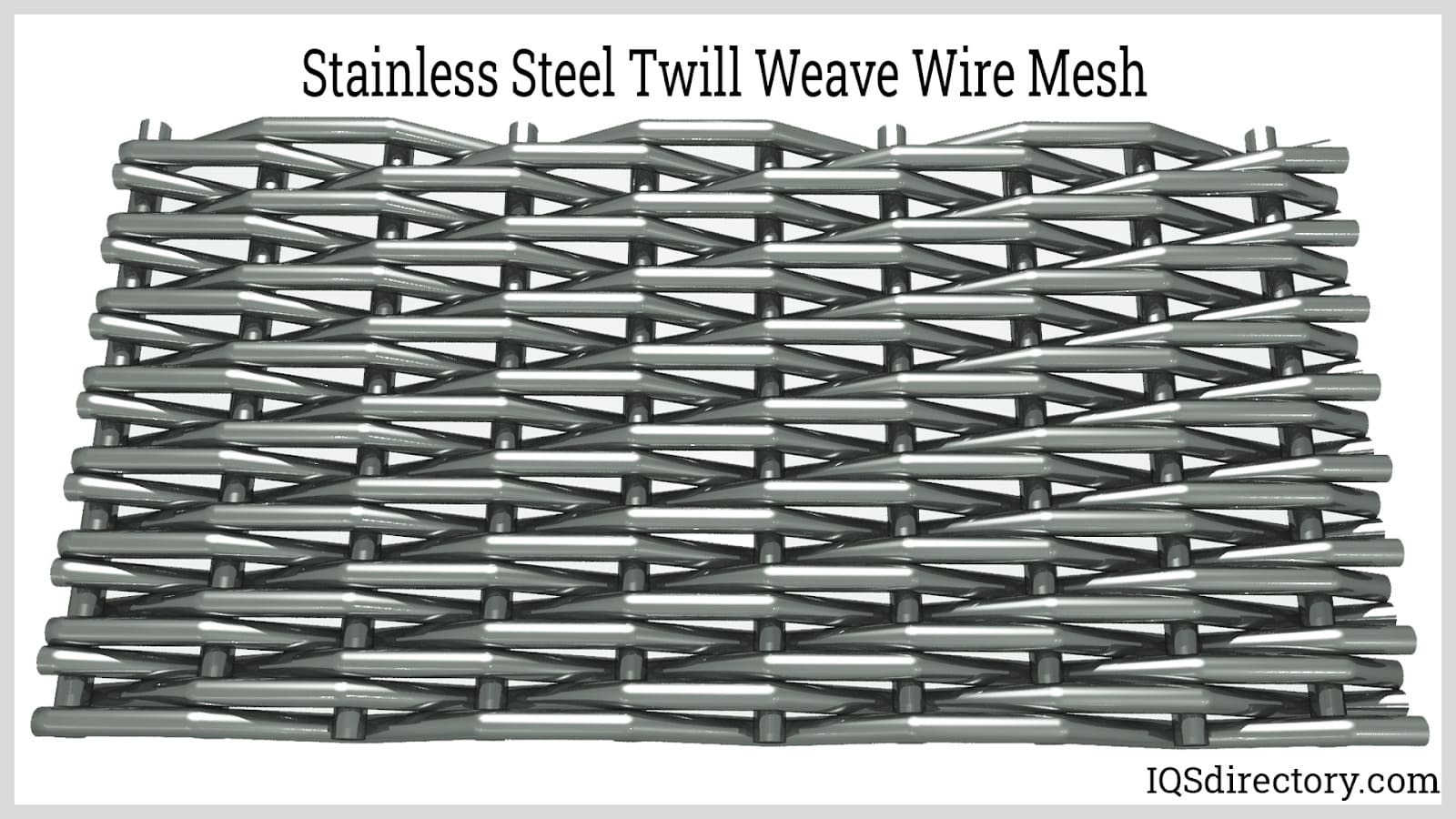

Twill Weave Wire Mesh

The twill weave pattern is ideal for weaving heavier and larger diameter wires. The pattern is formed by weaving warp wires over and under two weft wires or where a weft wire passes over and under two warp wires. The warp wire is inverted at the intersections to create a highly stable, rigid, and strong wire mesh. As the pattern develops, it becomes staggered, giving an appearance of parallel diagonal lines.

Twill weave wire mesh can support heavier loads and perform fine filtering. It is a basic component of the production of filters, colanders for aliments, chemical production, shielding, and mosquito nets. For filtering processes, it is made of stainless steel grades 304 and 316 due to their resistance to acids and wear.

Dutch Weave Wire Mesh

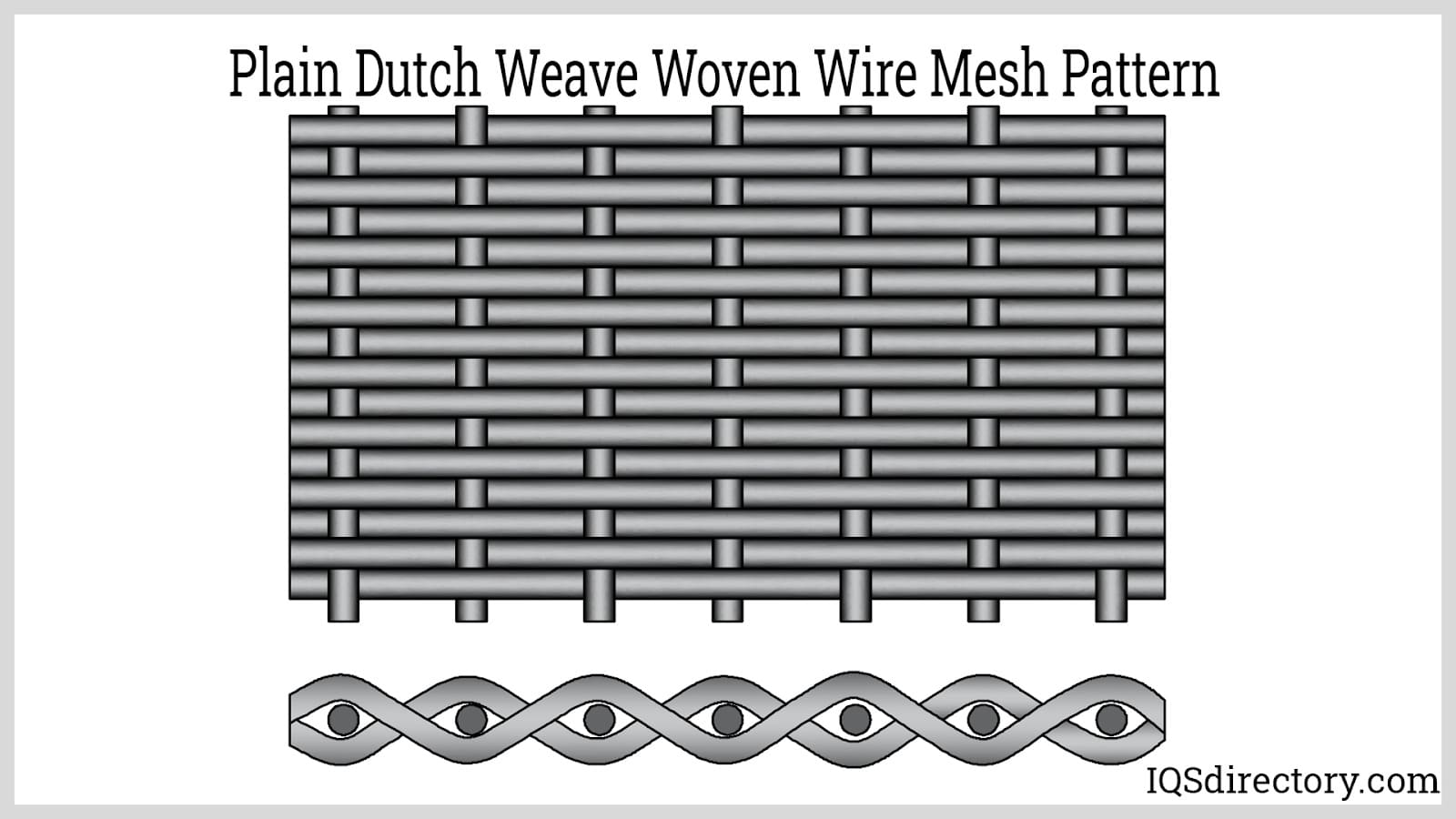

Dutch weave is different from plain weave wire mesh and twill weave wire mesh. In dutch weave wire mesh, the weft wires have a different diameter than the warp wires, with the warp wires being coarser to supply greater tensile strength. Weft wires are finer with smaller diameters to enhance filtering performance. The increased strength and finer openings make dutch weave wire mesh popular as a filtering cloth.

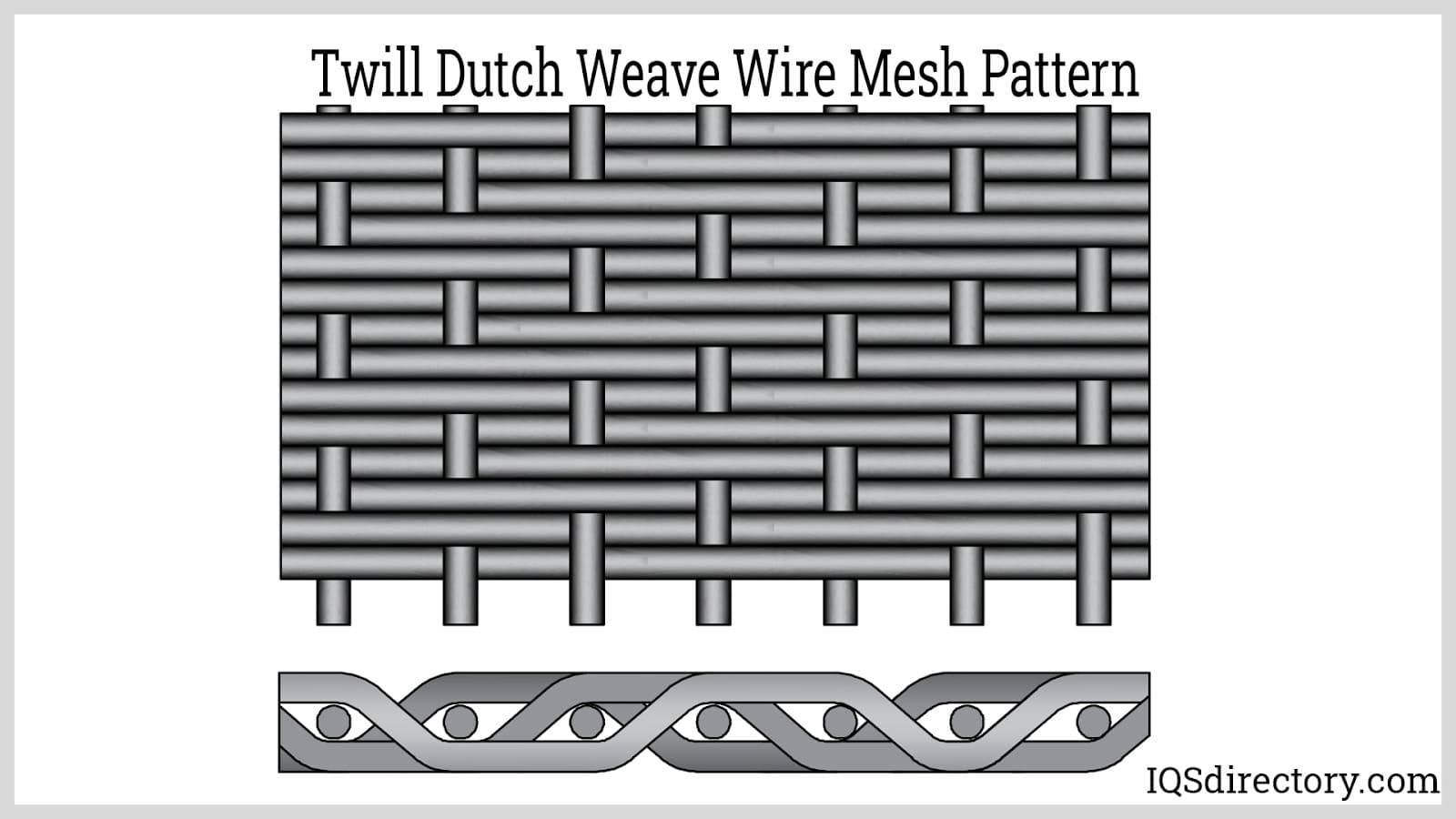

The dutch weaving process can be plain or twill, each of which has individual characteristics to fit the needs of different applications.

- Plain Dutch Weave Wire Mesh — Plain dutch weave combines the dutch weave process with plain wire weave. Using two different diameter wires, the coarse warp wire passes over and under the weft wire while the weft wire passes over and under the warp wire. The main advantages of plain dutch weave wire mesh are mechanical stability, finer wire openings, and exceptionally high tensile strength.

- Twill Dutch Weave Wire Mesh — Twill dutch weave is a combination of regular twill weave and dutch weave. The weft wire alternately passes over and under two warp wires creating a fine mesh in the direction of the warp wire, with the warp wires forming a coarser mesh in the same weave. Twill dutch weave is superior to normal twill weave due to the finer openings and the ability to support heavier loads for filtering applications.

The advantages of twill dutch weave wire mesh are its better filtering potential, tensile strength, the ability to filter exceptionally fine materials, and its stability.

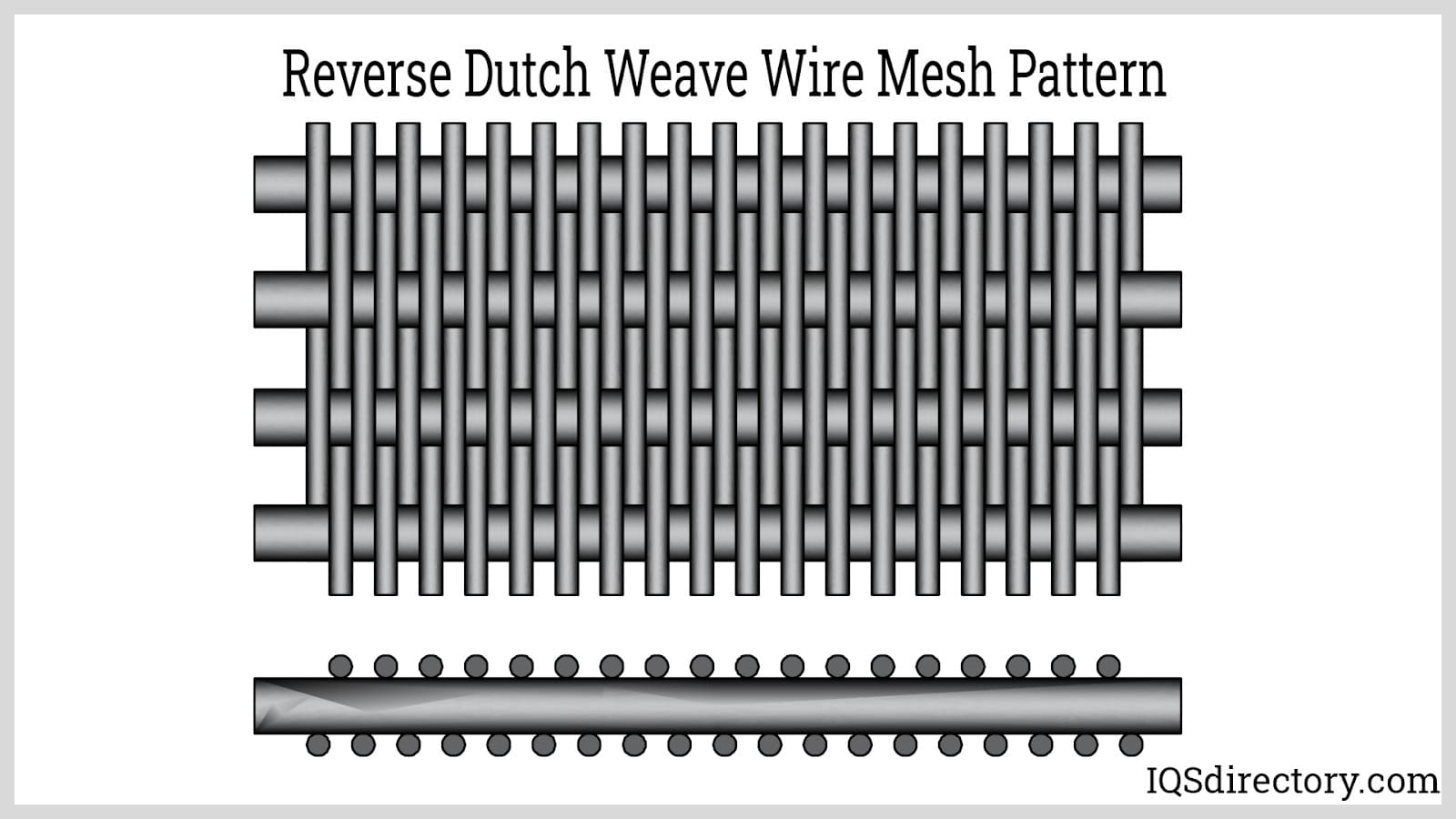

- Reverse Dutch Woven Wire Mesh — Reverse dutch woven wire mesh is the same as plain dutch woven wire mesh. The difference between the two weaves is how the weft and warp are woven, with the warp and weft wires being reversed. Thin warp wires are placed close together and woven with thicker weft wires, which creates higher strength in the warp wires. The reverse dutch weave is used in applications that need wire mesh with acoustic properties, mechanical strength, and throughput filtration.

Off Count Wire Mesh

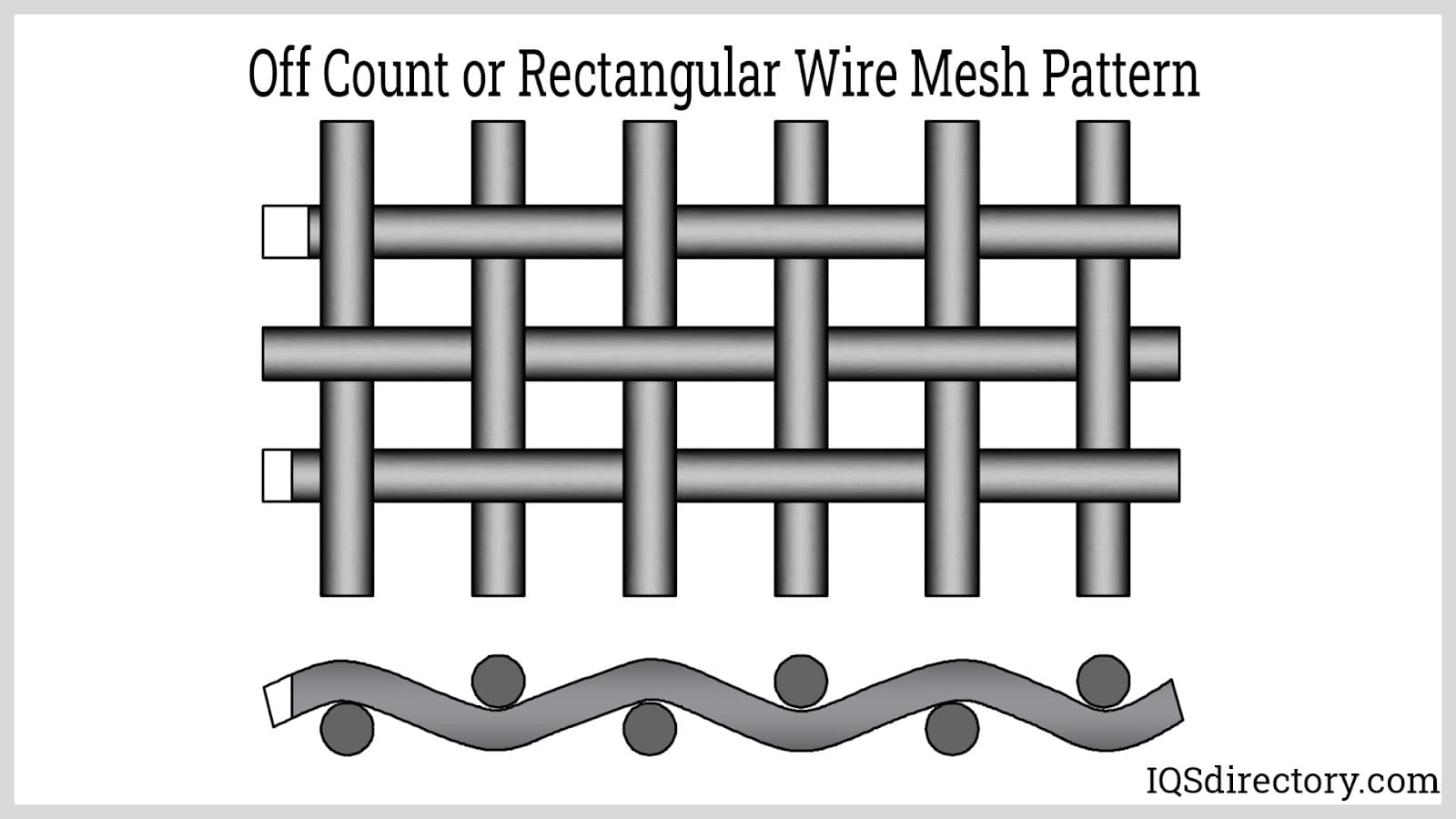

Off count wire mesh refers to wire mesh that does not have the same mesh count in both directions creating a rectangular rather than square mesh pattern. It is used in sifting and sizing operations to increase productivity and also where slight inaccuracies are not an issue.

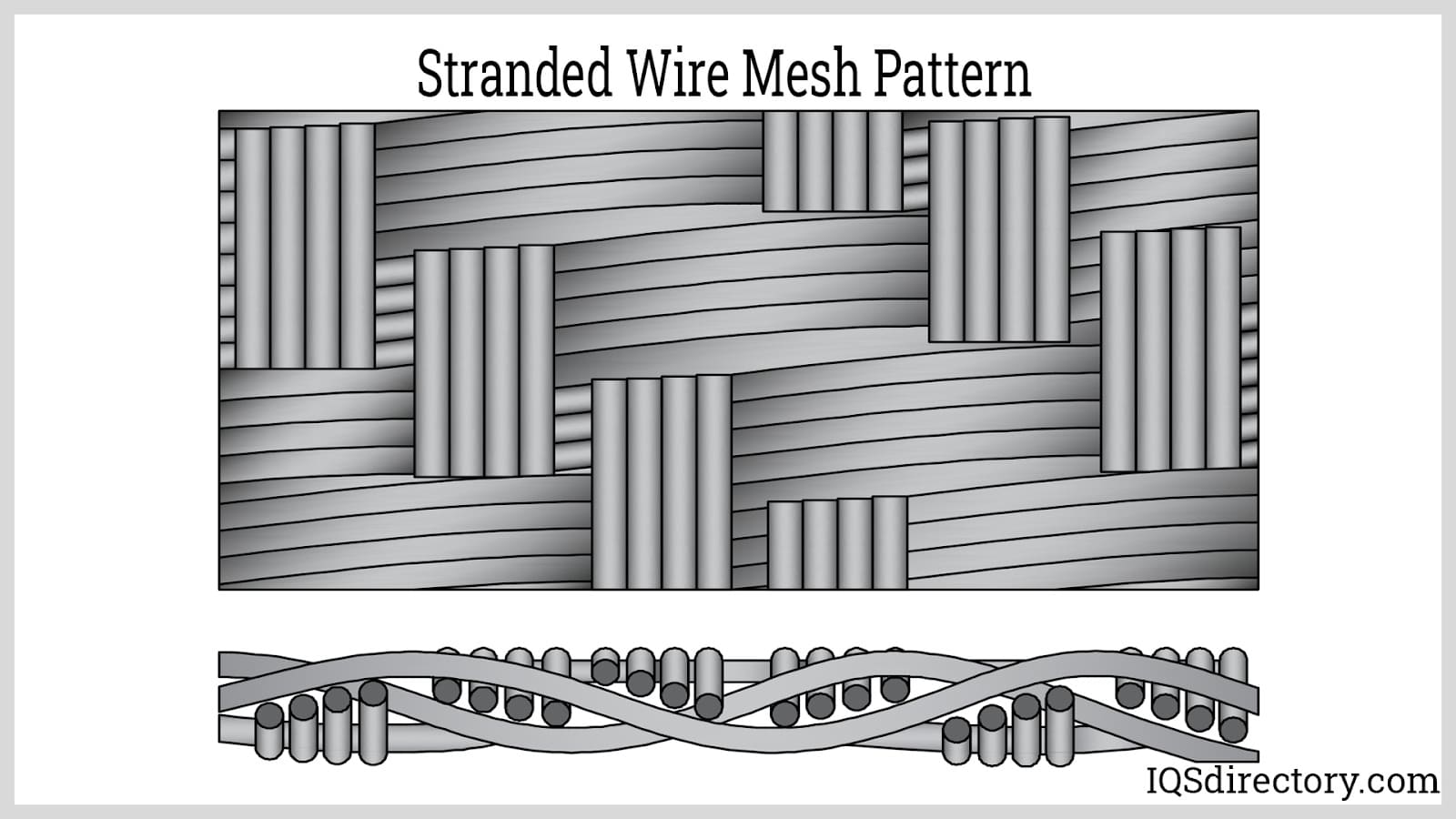

Stranded Weave Wire Mesh

Stranded weave wire mesh uses small-diameter weft and warp wire bunches that are woven in a plain square pattern. The use of multiple wires creates a twill style pattern that is extremely tight and strong. The tightness and density of the weave are useful in microfiltration cloth.

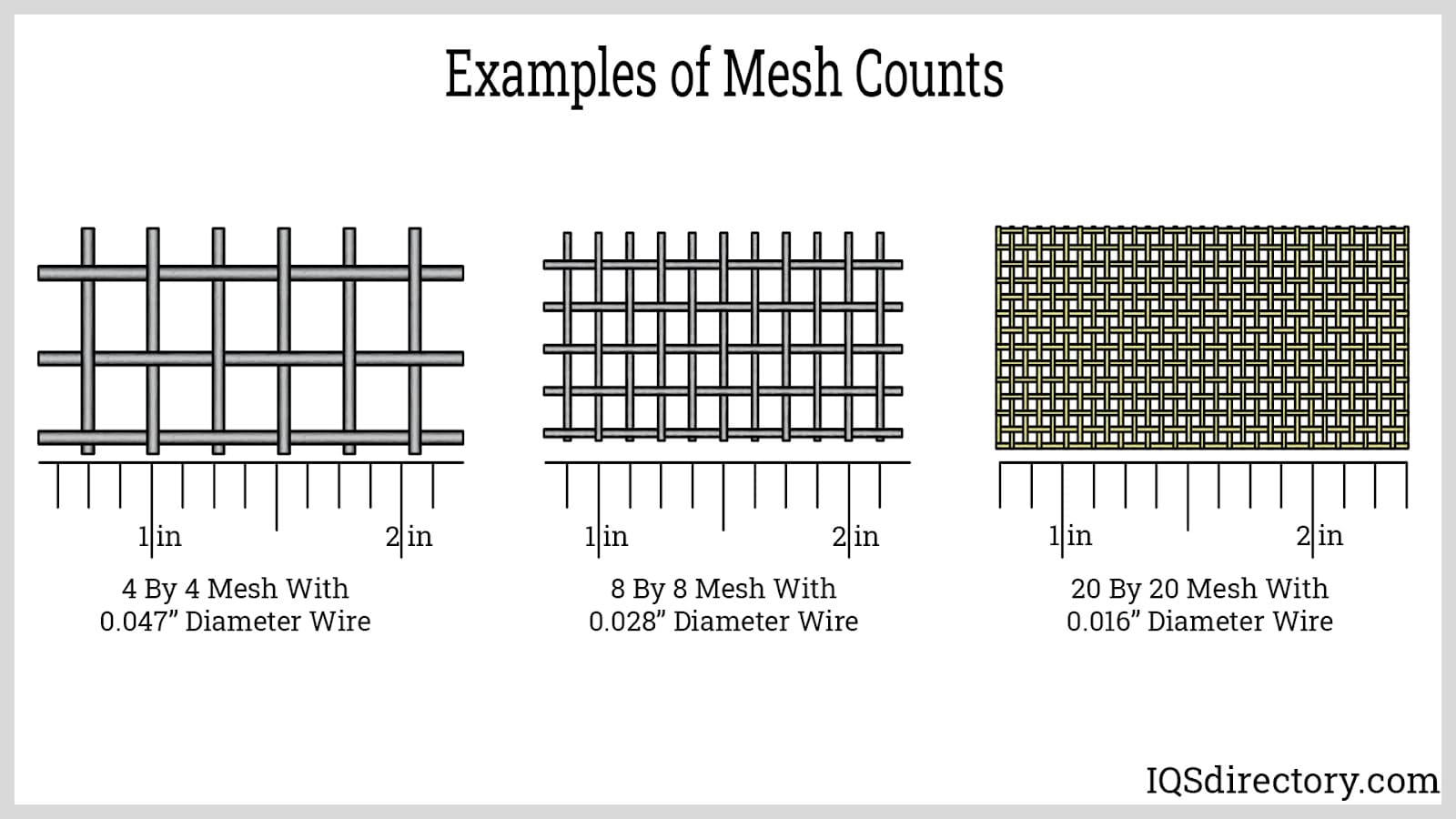

Mesh Count

The term mesh count refers to one of the most important principles of the wire mesh manufacturing industry. It is in regard to the number of openings per linear inch in wire mesh. The mesh count is determined by counting the number of openings in one linear inch from the center wire of a wire mesh. It is expressed as a single digit, such as no. 4 for a 4 by 4 mesh or no. 20 for a 20 by 20 mesh. The number is an indication of the number of openings in one linear inch.

Wire Mesh Edges

The two forms of wire mesh edges are raw and selvage. When wire mesh cloth is woven, the weft wires form an edge along the length of the roll and prevent the mesh from unraveling. In the case of a raw edge, those weft wires are uncovered at the edge of the wire mesh.

With selvage edge wire mesh, the border of the wire mesh is finished to increase the stability of the mesh and protect workers when handling the mesh. There are various methods for creating selvage edges, including looping the wires at the edge of the cloth.

share

-

CE Certified 250 Micron SS Mesh: Precision & Durability

NewsAug.15,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.14,2025

-

Precision CE Certified 250 Micron Stainless Steel Mesh

NewsAug.13,2025

-

CE Certified Metal Fine Mesh & Screen Fabric | Top Quality

NewsAug.12,2025

-

Premium CE Certified 250 Micron Stainless Steel Mesh

NewsAug.11,2025

-

CE Certified Stainless Steel Wire Mesh for Screen Printing

NewsAug.10,2025