okt . 11, 2024 15:25 Back to list

oem stainless steel wire & mesh

OEM Stainless Steel Wire and Mesh The Key to Versatile Industrial Solutions

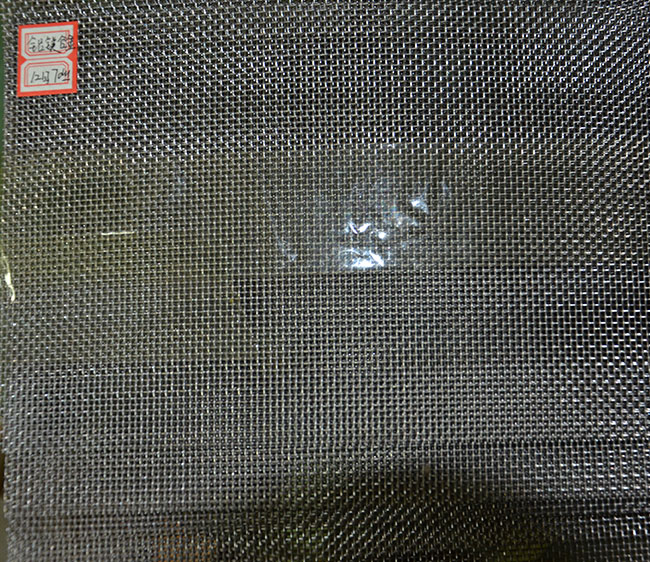

Stainless steel wire and mesh are essential materials in a multitude of industries, ranging from construction to food processing. Their unique properties make them ideal for applications requiring strength, durability, and corrosion resistance. As manufacturing needs evolve, OEM (Original Equipment Manufacturer) services have become increasingly important for producing customized stainless steel wire and mesh solutions tailored to specific requirements. This article explores the significance of OEM stainless steel wire and mesh, highlighting their applications and advantages.

Understanding OEM Stainless Steel Wire and Mesh

OEM stainless steel wire and mesh refer to customized wire and mesh products that are manufactured based on specific client specifications. These items can be produced in various sizes, shapes, and grades of stainless steel, catering to the diverse needs of different industries. The process typically involves close collaboration between manufacturers and clients to ensure that the final product meets precise performance standards and regulatory requirements.

Stainless steel, known for its excellent anti-corrosive properties, is an alloy primarily made of iron, chromium, and nickel. This composition grants stainless steel its durable and resilient characteristics, making it suitable for both indoor and outdoor applications. The versatility of stainless steel wire can be observed in its forms—ranging from fine wire used in electronic devices to thicker strands employed in safety cables.

Applications of Stainless Steel Wire and Mesh

1. Construction In the construction industry, stainless steel wire mesh is commonly used for reinforcement in concrete structures, ensuring stability and durability. Its resistance to rust and wear makes it a preferred choice for both residential and commercial buildings.

2. Food Processing The food industry requires stringent hygiene standards. Stainless steel wire mesh is widely utilized in food production and packaging processes, as it can withstand cleaning and sanitizing without degrading. Its non-toxic nature ensures that it does not contaminate food products.

3. Automotive In automotive manufacturing, stainless steel wire is used for various applications, including making springs, cables, and protective mesh. The materials offer the strength needed to endure the stresses of vehicle operation, while their corrosion resistance extends the lifespan of components.

oem stainless steel wire & mesh

4. Aerospace The aerospace industry demands materials that can perform under extreme conditions. Stainless steel wire and mesh are critical in the development of aircraft parts, including screens, filters, and safety components. Their lightweight yet robust nature supports the advancement of innovative aerospace designs.

5. Medical Devices In the medical field, OEM stainless steel wire and mesh are employed in the manufacturing of surgical instruments and implants. The biocompatibility, strength, and resistance to corrosion make stainless steel an ideal material for medical applications.

Advantages of OEM Stainless Steel Solutions

1. Customization One of the primary advantages of using OEM services for stainless steel wire and mesh is customization. Manufacturers can produce items that perfectly match the specifications, ensuring optimal performance in the intended application.

2. Quality Assurance OEM manufacturers often adhere to stringent quality control processes. This ensures that every batch of wire or mesh produced meets the highest standards, providing reliability and safety in critical applications.

3. Cost-Effectiveness While custom solutions may seem more expensive initially, they can lead to significant long-term savings. Customized stainless steel wire and mesh can enhance product performance and durability, reducing the need for replacements or repairs.

4. Innovation Working with OEM manufacturers encourages innovation. Engineers and designers can collaborate to develop new products that push the boundaries of current technology, resulting in superior solutions for complex challenges.

In conclusion, OEM stainless steel wire and mesh play a pivotal role in various industries, providing tailored solutions that meet specific requirements. Their strength, durability, and resistance to corrosion make them indispensable in applications ranging from construction to healthcare. By leveraging the benefits of OEM services, businesses can innovate and enhance their operations, ensuring they remain competitive in an ever-evolving market.

share

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025

-

CE Certification Buy Wire Mesh Fence for High Security and Durability

NewsJul.30,2025

-

Stainless Steel Mesh Filter Discs for Precise Filtration Solutions

NewsJul.29,2025