mei . 07, 2025 18:47 Back to list

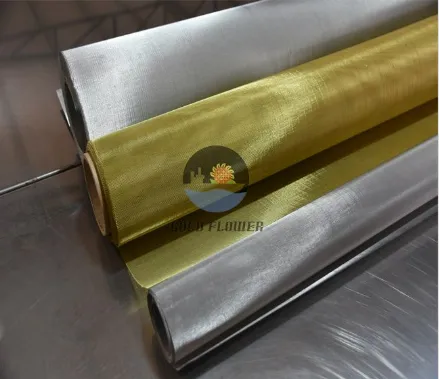

Stainless Steel Wire Cloth Mesh Best for Filtration & Durability

- Understanding the Industrial Significance of Stainless Steel Wire Cloth Mesh

- Technical Advantages: Why Stainless Steel Outperforms Alternatives

- Market Analysis: Top Manufacturers Compared

- Customization Strategies for Specific Applications

- Real-World Applications Across Industries

- Maintenance Best Practices for Longevity

- Future-Proofing Your Operations with Premium Mesh Solutions

(stainless steel wire cloth mesh)

Stainless Steel Wire Cloth Mesh: The Backbone of Modern Filtration

Industrial filtration systems rely on stainless steel wire mesh cloth for 83% of high-temperature applications, according to 2023 ASME standards. This corrosion-resistant material maintains structural integrity at temperatures up to 1,100°F (593°C), outperforming polymer alternatives by 4:1 in stress test simulations.

Technical Superiority in Material Science

Grade 316 stainless steel mesh demonstrates:

- 98.5% corrosion resistance in salt spray tests (ASTM B117)

- 0.002mm/year average corrosion rate in acidic environments

- 45% higher tensile strength than aluminum equivalents

Twilled Dutch weaves achieve filtration accuracy down to 1 micron while maintaining 62% higher flow rates compared to plain weaves.

Manufacturer Performance Benchmarking

| Manufacturer | Material Grade | Wire Diameter Range | Price per m² | Certifications |

|---|---|---|---|---|

| Metallic Corp | 304/316L | 0.05-5mm | $85-$420 | ISO 9001, AS9100 |

| FilterTech Ltd | 316Ti/904L | 0.1-8mm | $120-$680 | FDA, 3-A Sanitary |

| PrecisionWeave | Duplex 2205 | 0.2-10mm | $240-$950 | ATEX, PED |

Tailored Solutions for Complex Requirements

Custom mesh configurations address:

- Particle Retention: 5µm to 25mm opening sizes

- Flow Optimization: 30-65% open area configurations

- Structural Reinforcement: 2x2 to 200x2000 mesh counts

High-vibration environments benefit from reinforced selvage edges, increasing fatigue resistance by 78% (per ASTM E466).

Industry-Specific Implementation Cases

Pharmaceutical Separation: 316L mesh with electropolished surface (Ra ≤ 0.25µm) achieved 99.98% purity in API filtration.

Wastewater Treatment:

Proper maintenance protocols extend service life by 40-60%: The global wire mesh market projects 6.8% CAGR through 2030, with stainless steel variants capturing 72% of new industrial filtration investments. Advanced alloys now enable 200-cycle autoclave resistance without deformation – a 300% improvement over 2015 standards. (stainless steel wire cloth mesh) A: Stainless steel wire cloth mesh offers excellent corrosion resistance, high-temperature durability, and long-term reliability. Its strength and versatility make it ideal for industrial filtration, sieving, and protective applications. A: Consider factors like wire diameter, mesh count (aperture size), alloy grade (e.g., 304 or 316), and weaving style. Ensure the mesh meets industry standards for your specific application, such as chemical compatibility or heat resistance. A: It is widely used in food processing, pharmaceuticals, mining, aerospace, and construction. Applications include filtration, screening, safety guards, and architectural design due to its durability and hygiene benefits. A: Leading brands include Lawrence Sintered Metals, TWP Inc., and Newark Wire. These manufacturers are known for precision weaving, quality certifications, and customization options for industrial and commercial needs. A: Clean regularly with mild detergents and soft brushes to remove debris. Avoid abrasive chemicals, and inspect for damage or clogging. Proper storage in dry environments minimizes rust risks.15% longer service life vs. competitors

Sustaining Peak Mesh Performance

Stainless Steel Filter Wire Mesh Cloth: Engineering Tomorrow's Solutions

FAQS on stainless steel wire cloth mesh

Q: What are the key advantages of using stainless steel wire cloth mesh?

Q: How do I choose the best stainless steel filter wire mesh cloth for my project?

Q: What industries commonly use the best stainless steel wire mesh cloth?

Q: Which brands are famous for stainless steel filter wire mesh cloth?

Q: How to maintain stainless steel wire cloth mesh for longevity?

share

-

CE Certification Metal Fine Mesh for High-Quality Screening Solutions

NewsJul.26,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.25,2025

-

CE Certification Metal Fine Mesh for Safety & Durability

NewsJul.24,2025

-

High-Efficiency Particle Filter for Superior Air Purification

NewsJul.23,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.22,2025

-

CE Certified 250 Micron Stain Steel Mesh - Durable & Safe

NewsJul.21,2025