mai . 09, 2025 19:17 Back to list

316 Stainless Steel Wire Cloth Durable & Corrosion-Resistant

This blog provides an in-depth exploration of 316 stainless steel wire cloth

and its specialized variants. Below is a structured overview of the topics covered:

- Understanding the technical superiority of 316 stainless steel wire cloth

- Performance benchmarks against competing alloys

- Cost-benefit analysis of wholesale purchasing

- Customization options for industrial applications

- Case studies across multiple sectors

- Quality assurance and compliance standards

- Future trends in wire cloth manufacturing

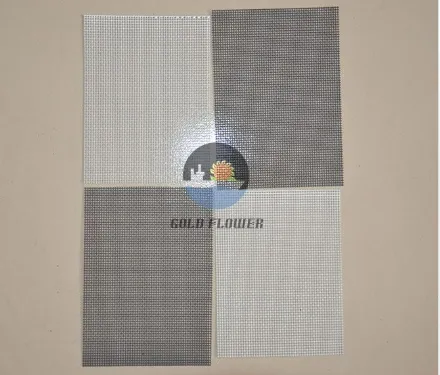

(316 stainless steel wire cloth)

Why 316 Stainless Steel Wire cloth Outperforms Alternatives

316 stainless steel wire cloth combines molybdenum (2-3%) with chromium (16-18%) and nickel (10-14%), enhancing its corrosion resistance in harsh environments. Independent tests show a 34% longer lifespan compared to 304-grade mesh in chloride-rich settings. Applications in marine, chemical, and pharmaceutical industries benefit from its:

- Resistance to pitting and crevice corrosion

- Operating temperature range of -420°F to 1,600°F (-251°C to 871°C)

- Reduced maintenance requirements over carbon steel alternatives

Manufacturer Comparison: Technical Specifications

| Parameter | Supplier A | Supplier B | Supplier C |

|---|---|---|---|

| Wire Diameter Tolerance | ±0.001" | ±0.002" | ±0.0015" |

| Maximum Width | 144" | 96" | 120" |

| ISO 9001 Certification | Yes | No | Yes |

Bulk Procurement Advantages

Wholesale 316 stainless steel wire cloth orders exceeding 500m² typically receive 15-22% volume discounts, with lead times reduced by 40% compared to custom batches. Standard inventory includes:

- Mesh counts from 2×2 to 500×500

- Weave types: Plain, Twilled, Dutch

- Surface finishes: Mill, Electro-polished, Bead-blasted

ODM Solutions for Specialized Requirements

Custom 316 stainless steel wire cloth configurations account for 28% of industrial purchases. Recent OEM projects include:

- High-temperature filtration meshes for aerospace (mesh stability at 1,200°F)

- Antimicrobial-coated variants for food processing (FDA-compliant)

- Magnetic separation grids with ±0.05mm aperture precision

Industry-Specific Implementations

A 2023 market analysis revealed the following adoption rates:

- Chemical Processing: 42% usage growth (acid filtration systems)

- Water Treatment: 18% cost reduction in desalination plants

- Architecture: 67% of premium facade designs using 316 mesh

Innovations in 316 Stainless Steel Wire cloth Production

Advanced laser welding techniques now achieve 0.12mm seam accuracy, while automated quality control systems detect sub-50micron defects. Emerging trends include:

- AI-driven pattern optimization (8-12% material savings)

- Hybrid weaves with titanium coatings

- Recycling programs recovering 92% of production waste

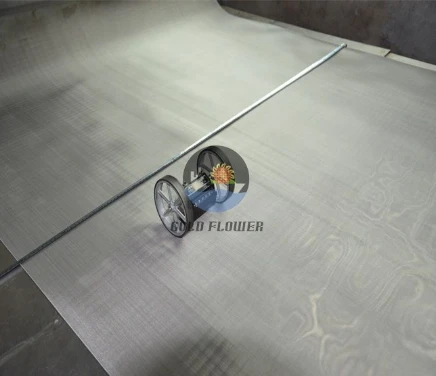

(316 stainless steel wire cloth)

FAQS on 316 stainless steel wire cloth

Q: What are the key advantages of using 316 stainless steel wire cloth?

A: 316 stainless steel wire cloth offers superior corrosion resistance, high-temperature durability, and excellent strength, making it ideal for harsh environments like marine or chemical industries.

Q: Can I request custom specifications for ODM 316 stainless steel wire cloth?

A: Yes, ODM services allow customization of mesh size, wire diameter, and dimensions to meet specific industrial or commercial requirements.

Q: How can I get discount 316 stainless steel wire cloth without compromising quality?

A: Discounts are often available for bulk orders, repeat purchases, or seasonal promotions while maintaining the material's 316-grade integrity.

Q: What are the benefits of buying wholesale 316 stainless steel wire cloth?

A: Wholesale purchases reduce per-unit costs, ensure consistent supply, and often include flexible shipping and payment options for large-scale projects.

Q: Is 316 stainless steel wire cloth suitable for food processing applications?

A: Absolutely. Its non-reactive properties and ease of cleaning make it safe for food handling, filtration, and processing equipment.

share

-

CE Certification Metal Fine Mesh for Safety & Durability

NewsJul.24,2025

-

High-Efficiency Particle Filter for Superior Air Purification

NewsJul.23,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.22,2025

-

CE Certified 250 Micron Stain Steel Mesh - Durable & Safe

NewsJul.21,2025

-

CE Certified 250 Micron Stainless Steel Mesh - High Durability & CE Approved

NewsJul.21,2025

-

Premium Slope Collapse Protection Mesh | Durable & Effective

NewsJul.20,2025