feb . 10, 2025 11:11 Back to list

buy crimped wire mesh machine

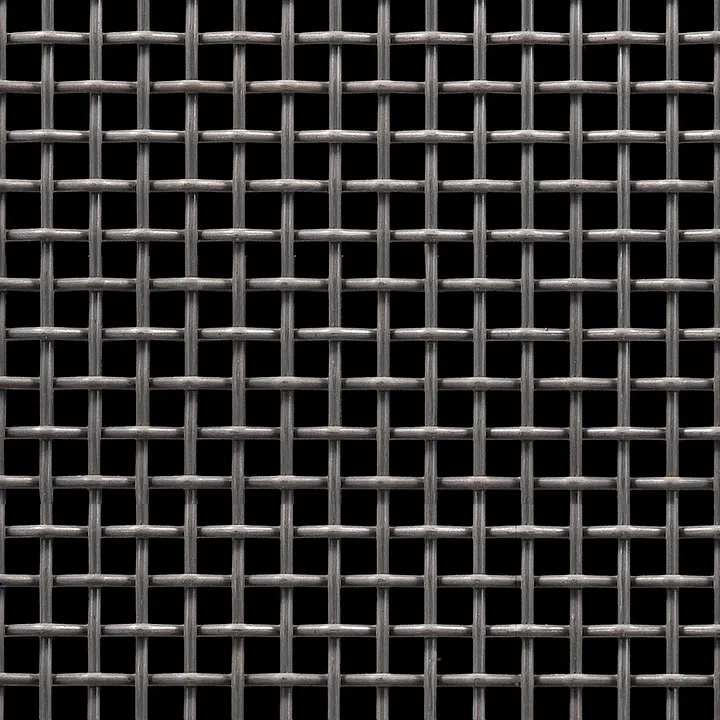

Crimped wire mesh machines have revolutionized the manufacturing sector by creating versatile wire mesh products used in various industries, such as mining, construction, and agriculture. Investing in the right crimped wire mesh machine can significantly enhance productivity and ensure high-quality output tailored to your specific needs.

Authority in the field is established through a combination of expertise, consistent quality output, and reliability. Market leaders often have a history of using cutting-edge technologies and complying with industry standards when manufacturing these machines. Engaging directly with manufacturers who demonstrate a track record of innovation and customer satisfaction can provide an additional layer of confidence in your purchase. Moreover, attending industry forums, exhibitions, and training sessions not only broadens your knowledge base but also positions you within a network of influential players, providing valuable insights and support for your investment. Trustworthiness in your investment can be assured through meticulous research and verification of machine manufacturers or suppliers. Reputable companies typically offer warranties, demonstrations, and after-sales support, reassuring buyers of their continued commitment to product quality and service. Customer reviews, testimonials, and case studies from similar industry applications are invaluable resources for gauging satisfaction and reliability. Look for detailed accounts of performance, durability, and customer service experiences to make a well-informed decision. Additionally, financial considerations should not be underestimated. Crimped wire mesh machines often represent a significant capital investment. Some manufacturers offer flexible financing options, which can ease the financial burden and align costs more closely with your cash flow cycle. Weigh these options carefully, considering the potential return on investment in terms of productivity gains and market demand fulfillment. In summary, acquiring a crimped wire mesh machine is a strategic investment that combines technical insight, industry expertise, and verified trust in manufacturers. Functionality and reliability should always take precedence over initial cost concerns, as these machines form the backbone of your production capabilities. By grounding your decision in experience, proficiency, authority, and trustworthiness, you can enhance your operational capacity while maintaining a competitive edge in the ever-evolving wire mesh industry.

Authority in the field is established through a combination of expertise, consistent quality output, and reliability. Market leaders often have a history of using cutting-edge technologies and complying with industry standards when manufacturing these machines. Engaging directly with manufacturers who demonstrate a track record of innovation and customer satisfaction can provide an additional layer of confidence in your purchase. Moreover, attending industry forums, exhibitions, and training sessions not only broadens your knowledge base but also positions you within a network of influential players, providing valuable insights and support for your investment. Trustworthiness in your investment can be assured through meticulous research and verification of machine manufacturers or suppliers. Reputable companies typically offer warranties, demonstrations, and after-sales support, reassuring buyers of their continued commitment to product quality and service. Customer reviews, testimonials, and case studies from similar industry applications are invaluable resources for gauging satisfaction and reliability. Look for detailed accounts of performance, durability, and customer service experiences to make a well-informed decision. Additionally, financial considerations should not be underestimated. Crimped wire mesh machines often represent a significant capital investment. Some manufacturers offer flexible financing options, which can ease the financial burden and align costs more closely with your cash flow cycle. Weigh these options carefully, considering the potential return on investment in terms of productivity gains and market demand fulfillment. In summary, acquiring a crimped wire mesh machine is a strategic investment that combines technical insight, industry expertise, and verified trust in manufacturers. Functionality and reliability should always take precedence over initial cost concerns, as these machines form the backbone of your production capabilities. By grounding your decision in experience, proficiency, authority, and trustworthiness, you can enhance your operational capacity while maintaining a competitive edge in the ever-evolving wire mesh industry.

share

Latest news

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025

-

CE Certification Buy Wire Mesh Fence for High Security and Durability

NewsJul.30,2025

-

Stainless Steel Mesh Filter Discs for Precise Filtration Solutions

NewsJul.29,2025