feb . 19, 2025 08:25 Back to list

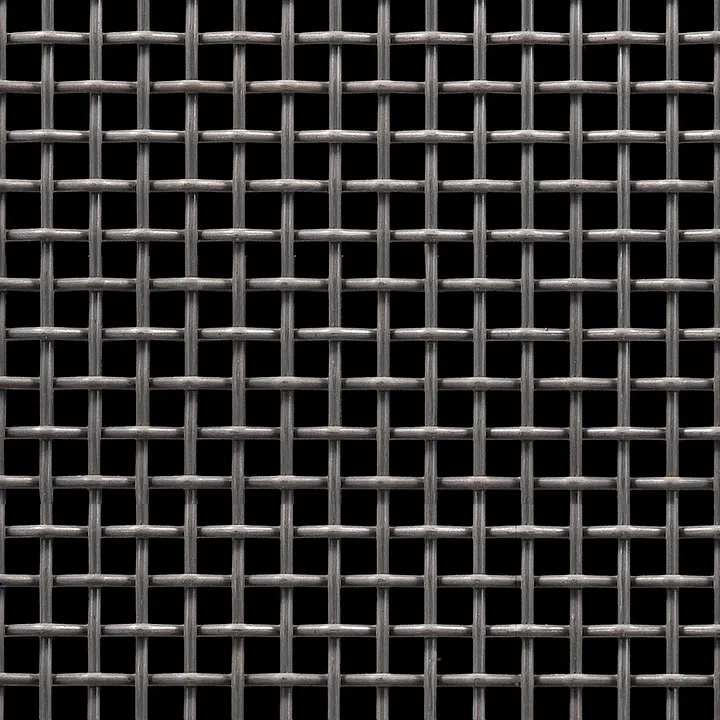

400 stainless steel mesh

Navigating the myriad of options for purchasing stainless steel mesh can be as intricate as the mesh itself. As a versatile material, stainless steel mesh is utilized across various industries, from construction and architecture to automotive and filtration systems. Choosing the right type of mesh not only impacts the quality of your project but also its longevity and safety. Drawing from years of industry expertise, this guide provides insights and practical advice on how to purchase stainless steel mesh effectively.

Establishing long-term relationships with suppliers can offer significant advantages. Long-term partnerships often result in more favorable pricing, priority in delivery schedules, and access to the latest innovations in mesh technology. Suppliers are more likely to go the extra mile in ensuring that your specific needs are met efficiently. The trustworthiness of the supplier also extends to delivery capabilities. Timeliness and condition upon delivery are essential factors, particularly when operating under strict project deadlines. A trusted supplier should guarantee timelines and offer flexible delivery options to accommodate sudden changes often encountered in project schedules. Pricing should be approached with a comprehensive understanding of the total cost. Initial quote comparisons should account for shipping, potential tariff considerations, and long-term value in terms of product lifespan. While initial costs may vary significantly, cheaper alternatives could incur higher long-term costs if quality compromises lead to replacements or repairs. For those new to purchasing stainless steel mesh, engaging with a consultant who specializes in material sourcing can be beneficial. Their expertise can navigate complex purchasing cycles, ensuring efficient and accurate acquisition aligned with project demands and budgets. In summary, purchasing stainless steel mesh demands a balance between technical requirements, supplier reputation, and cost management. As an industry insider, understanding these components allows for informed decisions that uphold the integrity and quality of your project. This proactive approach not only ensures successful project completion but also enhances the safety and efficacy of the application, cementing your reputation within your respective field.

Establishing long-term relationships with suppliers can offer significant advantages. Long-term partnerships often result in more favorable pricing, priority in delivery schedules, and access to the latest innovations in mesh technology. Suppliers are more likely to go the extra mile in ensuring that your specific needs are met efficiently. The trustworthiness of the supplier also extends to delivery capabilities. Timeliness and condition upon delivery are essential factors, particularly when operating under strict project deadlines. A trusted supplier should guarantee timelines and offer flexible delivery options to accommodate sudden changes often encountered in project schedules. Pricing should be approached with a comprehensive understanding of the total cost. Initial quote comparisons should account for shipping, potential tariff considerations, and long-term value in terms of product lifespan. While initial costs may vary significantly, cheaper alternatives could incur higher long-term costs if quality compromises lead to replacements or repairs. For those new to purchasing stainless steel mesh, engaging with a consultant who specializes in material sourcing can be beneficial. Their expertise can navigate complex purchasing cycles, ensuring efficient and accurate acquisition aligned with project demands and budgets. In summary, purchasing stainless steel mesh demands a balance between technical requirements, supplier reputation, and cost management. As an industry insider, understanding these components allows for informed decisions that uphold the integrity and quality of your project. This proactive approach not only ensures successful project completion but also enhances the safety and efficacy of the application, cementing your reputation within your respective field.

share

Latest news

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025

-

CE Certification Buy Wire Mesh Fence for High Security and Durability

NewsJul.30,2025

-

Stainless Steel Mesh Filter Discs for Precise Filtration Solutions

NewsJul.29,2025