des . 11, 2024 11:18 Back to list

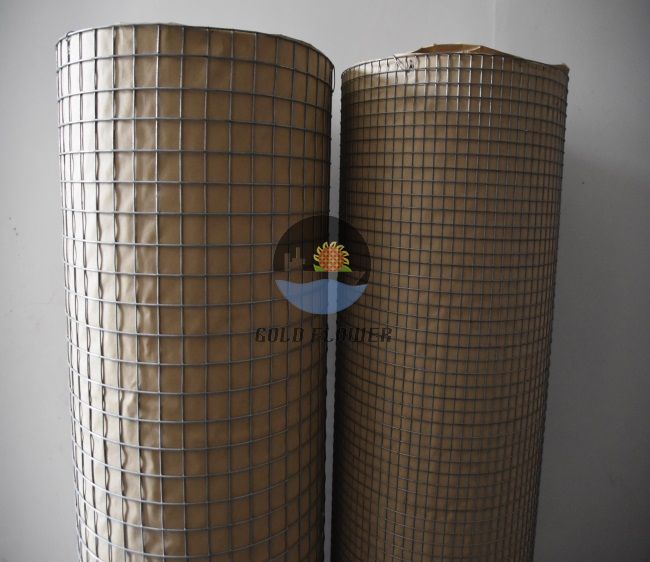

mesh wire filter

The Importance of Mesh Wire Filters in Various Industries

Mesh wire filters play a crucial role in a variety of industrial applications, enhancing both the efficiency and longevity of machinery. These filters, made from woven or knitted wire mesh, serve to separate solid particles from liquids or gases, making them indispensable in sectors such as water treatment, food processing, pharmaceuticals, and manufacturing.

Understanding Mesh Wire Filters

Mesh wire filters are designed with different mesh sizes to cater to specific filtration needs. The size of the openings in the mesh determines the type of substances that can be filtered out. For instance, a filter with larger openings can remove coarser particles, while finer mesh filters are capable of capturing smaller particulates. This versatility makes them ideal for numerous applications, where precise filtration is required.

Applications in Water Treatment

One of the most significant applications of mesh wire filters is in the water treatment industry. These filters are used to remove debris, sediments, and other contaminants from water sources before the water is subjected to further purification processes. By using mesh wire filters, facilities can prevent larger particles from clogging pumps and equipment, thereby reducing maintenance costs and extending the lifespan of their systems. Furthermore, ensuring a clean water source is crucial for public health and safety, making these filters a vital component in environmental management.

Role in the Food Processing Industry

mesh wire filter

In the food processing sector, cleanliness and safety are paramount. Mesh wire filters help ensure that raw materials are free from impurities before they are processed. For example, during the production of beverages, these filters can be employed to eliminate pulp, seeds, or other unwanted particles, guaranteeing a clear and pure end product. Additionally, mesh filters are integral in various cooking processes and can be found in items like tea strainers or oil fryers, ensuring that food products meet rigorous quality standards.

Pharmaceutical Applications

The pharmaceutical industry also relies heavily on mesh wire filters for both production and research purposes. These filters help in the separation of active ingredients from excipients and contaminants in drug formulation processes. The high-quality filtration provided by mesh wire filters ensures that the final pharmaceutical products are safe for consumption and meet regulatory standards. Furthermore, in laboratories, these filters are often used to prepare samples, ensuring that results are accurate and reliable.

Manufacturing and Beyond

In manufacturing, mesh wire filters are utilized in diverse applications, including the filtering of lubricants and coolants in machinery. This helps prolong the life of equipment and enhances operational efficiency by keeping fluids free from harmful debris. Moreover, in the automotive industry, mesh filters are tasked with filtering out particulates in fuel and oil systems, thereby improving engine performance and durability.

Conclusion

In conclusion, mesh wire filters are an essential component across multiple industries, providing effective filtration solutions that contribute to operational efficiency, product quality, and safety. Their versatility in design allows them to meet specific filtration requirements, making them suitable for a wide range of applications, from water treatment and food processing to pharmaceuticals and manufacturing. As industries continue to evolve, the importance of reliable filtration systems like mesh wire filters will only grow, underscoring their pivotal role in modern industrial practices. Investing in high-quality mesh wire filters is not just a choice; it's a necessity for those aiming to maintain superior operational standards and safeguard public health.

share

-

CE Certified 250 Micron Stainless Steel Mesh for Precision & Durability

NewsAug.25,2025

-

Premium CE Certified Metal Fine Mesh for Precision & Safety

NewsAug.24,2025

-

Stainless Steel Wedge Wire Mesh: Durable, Precision Filtration

NewsAug.23,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision Filtration

NewsAug.22,2025

-

CE Certified 250 Micron SS Mesh - Precision Filtration & Strength

NewsAug.21,2025

-

CE Certified Woven Wire Mesh Filters | Premium Filtration Solutions

NewsAug.19,2025