des . 12, 2024 13:39 Back to list

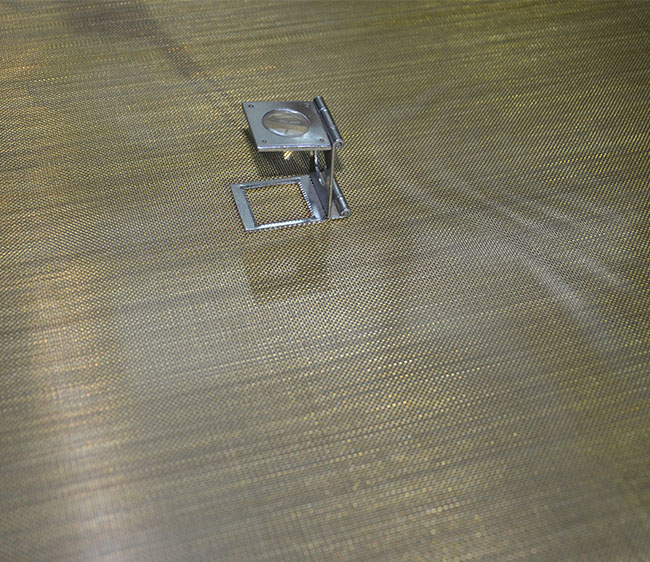

odm wire mesh fine

Understanding ODM Wire Mesh Fine A Comprehensive Overview

Wire mesh has become an indispensable component in diverse industrial applications, serving as a versatile solution for various filtration, screening, and construction needs. Among the various types of wire mesh available, ODM wire mesh fine stands out due to its specific characteristics and advantageous properties. This article delves into the intricacies of ODM wire mesh fine, exploring its manufacturing process, applications, benefits, and factors to consider when selecting the right mesh for your needs.

What is ODM Wire Mesh Fine?

ODM wire mesh fine refers to a type of woven wire mesh constructed from thin wire strands, typically made of stainless steel, carbon steel, or non-ferrous metals. The term fine denotes the mesh's smaller aperture or opening size, which is essential for applications requiring high precision filtering or screening. The specifications of ODM wire mesh fine can vary, with different wire gauges and mesh configurations available to suit specific purposes.

Manufacturing Process

The production of ODM wire mesh fine involves several stages, starting from wire drawing, where larger diameter rods are drawn down to the desired wire gauge. Afterward, the wires are woven into a mesh form using various weaving techniques, such as plain weave, twill weave, or Dutch weave. Each of these methods contributes to the final properties of the mesh, including strength, flexibility, and filtering capability.

Once woven, the wire mesh may undergo additional treatments, such as galvanizing or coating, to enhance its corrosion resistance and durability. Quality control measures are implemented throughout the process to ensure that the final product meets industry standards and client specifications.

Applications of ODM Wire Mesh Fine

The applications of ODM wire mesh fine are myriad, spanning across several industries

1. Filtration The fine mesh is ideal for applications requiring the separation of small particles from liquids or gases. This includes wastewater treatment, food and beverage filtration, and chemical processing.

2. Screening In mining and aggregate industries, fine wire mesh is used to separate materials by size. It effectively screens out fine dust and smaller particles while allowing larger fragments to pass through.

3. Civil Engineering In construction, ODM wire mesh fine is used in concrete reinforcement, helping to prevent cracking and ensuring structural integrity.

4. Safety and Security The fine mesh can be utilized in fencing and barrier applications, providing security while maintaining visibility.

5. Industrial Processes In various manufacturing processes, such as electronics and pharmaceuticals, ODM wire mesh fine aids in maintaining cleanliness and preventing contamination.

odm wire mesh fine

6. Agriculture Fine wire mesh is used for pest control, crop protection, and soil filtration, ensuring optimal growth conditions for plants.

Benefits of ODM Wire Mesh Fine

The advantages of using ODM wire mesh fine include

- Precision Its finely woven structure allows for high levels of precision in filtering applications, making it perfect for industries needing strict adherence to size specifications.

- Durability Typically made from high-strength materials, this mesh exhibits excellent durability, ensuring a long service life even in harsh environments.

- Corrosion Resistance Particularly when made from stainless steel, ODM wire mesh fine can resist rust and corrosion, making it suitable for applications exposed to moisture or chemicals.

- Versatility With a range of specifications available, it can be tailored to meet the specific requirements of various applications.

Factors to Consider When Choosing ODM Wire Mesh Fine

When selecting ODM wire mesh fine for your project, consider the following factors

- Wire Gauge Determine the appropriate wire diameter based on the strength and flexibility needed for your application.

- Mesh Size Choose the mesh aperture size according to the specific filtering or screening requirements.

- Material Select the right material based on environmental conditions and the nature of the substances being handled.

- Weaving Type Different weaving methods lend varying properties to the mesh. Evaluate which type best suits your application needs.

In conclusion, ODM wire mesh fine is a key player across numerous industries, contributing significantly to processes requiring filtration, screening, and structural reinforcement. Its unique characteristics and adaptability make it a valuable asset for businesses aiming for efficiency and quality. Understanding its attributes and applications will enable better-informed decisions in selecting the right wire mesh for specific needs.

share

-

Stainless Steel Wedge Wire Mesh: Durable, Precision Filtration

NewsAug.23,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision Filtration

NewsAug.22,2025

-

CE Certified 250 Micron SS Mesh - Precision Filtration & Strength

NewsAug.21,2025

-

CE Certified Woven Wire Mesh Filters | Premium Filtration Solutions

NewsAug.19,2025

-

High-Performance Particle Filters: Optimal Mediums & Applications

NewsAug.18,2025

-

Competitive Screen Mesh Price | 1/4", 1/8", 1/2" Wire Mesh Screens

NewsAug.17,2025