okt . 21, 2024 06:54 Back to list

Custom Metal Wire Grate Solutions for Versatile Applications and Enhanced Durability

Exploring the Versatility of OEM Metal Wire Grates

In today's fast-paced industrial landscape, efficiency and quality are paramount. One of the key players in enhancing productivity is the OEM (Original Equipment Manufacturer) metal wire grate. These versatile components have carved a niche in various applications, from manufacturing to food processing. This article delves into the characteristics, benefits, and applications of OEM metal wire grates, highlighting their importance in modern industries.

Understanding OEM Metal Wire Grates

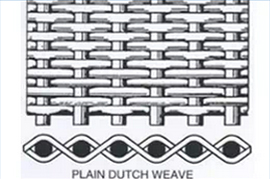

OEM metal wire grates are fabricated from high-quality materials, typically stainless steel or carbon steel, to ensure durability and strength. These grates are engineered to meet the specific requirements of original equipment manufacturers, making them integral parts of larger systems. The wire mesh design allows for optimal airflow and drainage while delivering a sturdy surface for diverse operations.

These grates can be custom-designed based on the specifications of the manufacturer, which can include variations in wire thickness, grid size, and material type. This customization is particularly beneficial as it allows businesses to tailor products to suit their unique operational needs.

Benefits of Using OEM Metal Wire Grates

1. Durability and Strength One of the most significant advantages of OEM metal wire grates is their robustness. Their construction typically resists corrosion, high temperatures, and heavy loads, making them suitable for demanding environments.

2. Customization OEM providers often work closely with clients to develop wire grates that meet specific performance and design criteria. This degree of customization ensures the final product integrates seamlessly into existing systems.

3. Improved Efficiency The open design of wire grates enhances airflow and reduces heat buildup, facilitating better performance in operations such as drying and cooling processes. Furthermore, the design allows for water, debris, and other materials to drain through easily, preventing clogging and promoting cleanliness.

4. Cost-Effectiveness While the initial investment in high-quality OEM metal wire grates may be higher than that of plastic or lower-quality alternatives, their durability and reduced need for replacement make them a cost-effective choice in the long run.

oem metal wire grate

5. Sustainability Many OEM metal wire grates are made from recyclable materials, contributing to a more sustainable production process. As industries increasingly focus on environmental impact, using metal wire grates aligns with eco-friendly initiatives.

Applications Across Industries

1. Food and Beverage Industry In food processing facilities, metal wire grates are used in conveyor systems and for supporting products during cooling or drying processes. They are easy to clean, which is crucial for maintaining hygiene standards.

2. Manufacturing In industrial settings, these grates are used in assembly lines and as load-bearing surfaces. Their ability to withstand heavy machinery and repetitive use makes them highly sought-after in manufacturing plants.

3. Waste Management Metal wire grates facilitate efficient waste sorting and processing, allowing for easy flow of materials while providing structural support. They are often used in recycling facilities and waste processing centers.

4. Agriculture In agricultural settings, wire grates are utilized in livestock operations for flooring and support structures, ensuring proper drainage and sanitation, which is vital for animal health.

5. Construction Construction sites employ OEM metal wire grates for scaffolding and temporary flooring solutions, offering robustness and safety for workers.

Conclusion

OEM metal wire grates are indispensable components in various industries, offering a blend of durability, customization, and efficiency. As businesses strive for operational excellence, embracing the advantages of these grates can lead to improved productivity, cost savings, and sustainability. By understanding the diverse applications and benefits, companies can make informed decisions about integrating OEM metal wire grates into their processes, ensuring they remain competitive in today's dynamic market. Whether in food processing, manufacturing, or agriculture, the versatility of metal wire grates is undeniable and continues to play a crucial role in enhancing industrial operations.

share

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025

-

CE Certification Buy Wire Mesh Fence for High Security and Durability

NewsJul.30,2025

-

Stainless Steel Mesh Filter Discs for Precise Filtration Solutions

NewsJul.29,2025