sep . 28, 2024 22:05 Back to list

High-Quality OEM Steel Mesh Solutions for Various Industrial Applications

The Versatility and Applications of OEM Steel Mesh

In today's fast-paced industrial landscape, the demand for high-quality materials has never been more pronounced. One such material that has gained considerable traction is OEM (Original Equipment Manufacturer) steel mesh. This specialized type of steel mesh has emerged as a versatile solution for various applications across different sectors. In this article, we will explore the characteristics, benefits, and diverse applications of OEM steel mesh.

What is OEM Steel Mesh?

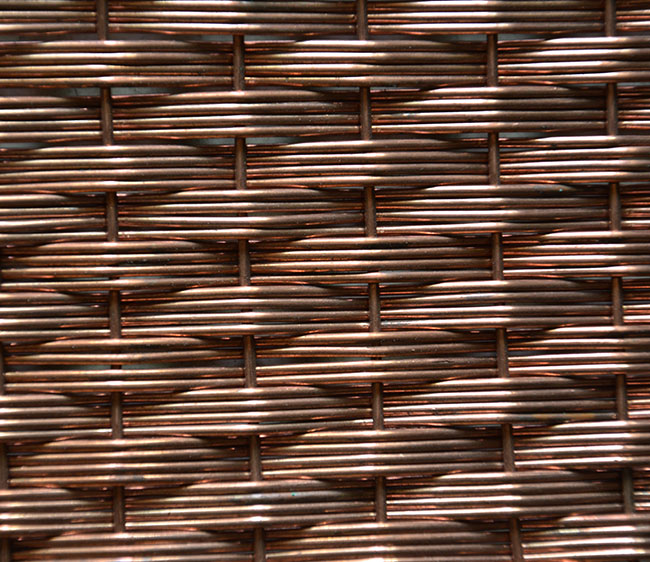

OEM steel mesh refers to a type of steel mesh that is specifically manufactured to meet the unique specifications and requirements of a particular industry or application. The term OEM indicates that these products are designed for a specific customer or market, often incorporating tailored features that enable optimal performance in various use cases. Made from high-quality steel, OEM steel meshes are typically produced through processes such as welding, weaving, or riveting, resulting in a robust and durable product.

Key Characteristics

One of the standout features of OEM steel mesh is its strength and durability. Made from high-tensile steel, it can withstand considerable stress and strain, making it ideal for heavy-duty applications. Additionally, steel mesh products can be coated with protective layers to resist corrosion and rust, extending their lifespan and maintaining aesthetic appeal.

Another important characteristic is their customizable design. OEM steel meshes can be made in various sizes, shapes, and configurations to meet specific customer needs. This flexibility enables them to serve different functions, whether as reinforcement materials, safety barriers, or decorative elements in construction projects.

Benefits of OEM Steel Mesh

1. Cost-Effectiveness By opting for OEM steel mesh, businesses can often reduce their overall production costs. Customization ensures that resources are utilized efficiently, minimizing waste and maximizing functionality.

2. Enhanced Performance Tailor-made solutions often result in better performance. OEM steel mesh can be engineered to meet strict industry standards and requirements, ensuring reliability in the most demanding environments.

3. Reduced Lead Times Engaging with an OEM manufacturer allows for streamlined processes. With a direct line to the producer, businesses can expect shorter lead times, enabling them to meet project deadlines and respond swiftly to market needs.

oem steel mesh

4. Sustainability Steel is a recyclable material, and many OEM manufacturers prioritize sustainable practices. By utilizing steel mesh in projects, companies can contribute to a more sustainable future by opting for eco-friendly materials.

Applications of OEM Steel Mesh

The applications of OEM steel mesh are vast and varied. Here are some key sectors where it plays a significant role

1. Construction In the construction industry, OEM steel mesh is commonly used for reinforcing concrete structures. It provides added strength and stability, ensuring that buildings can withstand various environmental forces.

2. Mining and Quarrying Steel mesh is utilized in mining operations for safety and operational efficiency. It can serve as rockfall protection, screening material, and even in the design of equipment used in extraction processes.

3. Automotive The automotive industry makes extensive use of OEM steel mesh in manufacturing components like filters, grilles, and safety barriers. The durability of steel mesh makes it an ideal choice for parts that must perform reliably in diverse conditions.

4. Agriculture In agricultural applications, OEM steel mesh is often used for fencing, crop protection, and sorting equipment. Its strength and durability ensure that it can withstand weather elements and the rigors of farm life.

5. Aerospace The aerospace sector, which requires materials with high strength-to-weight ratios, also employs OEM steel mesh for various components, including lightweight structures and filters.

Conclusion

OEM steel mesh represents a blend of innovation, customization, and performance across multiple industries. As businesses continue to seek solutions that enhance efficiency and safety, the relevance of OEM steel mesh will only grow. Its versatility in applications—from construction to aerospace—underlines its importance as a foundational material in modern industrial practices. For companies looking to optimize their operations, investing in OEM steel mesh could be a pivotal decision, leading to enhanced productivity, sustainability, and competitive advantage in an increasingly material-demanding world.

share

-

Stainless Steel Wedge Wire Mesh: Durable, Precision Filtration

NewsAug.23,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision Filtration

NewsAug.22,2025

-

CE Certified 250 Micron SS Mesh - Precision Filtration & Strength

NewsAug.21,2025

-

CE Certified Woven Wire Mesh Filters | Premium Filtration Solutions

NewsAug.19,2025

-

High-Performance Particle Filters: Optimal Mediums & Applications

NewsAug.18,2025

-

Competitive Screen Mesh Price | 1/4", 1/8", 1/2" Wire Mesh Screens

NewsAug.17,2025