okt . 13, 2024 02:30 Back to list

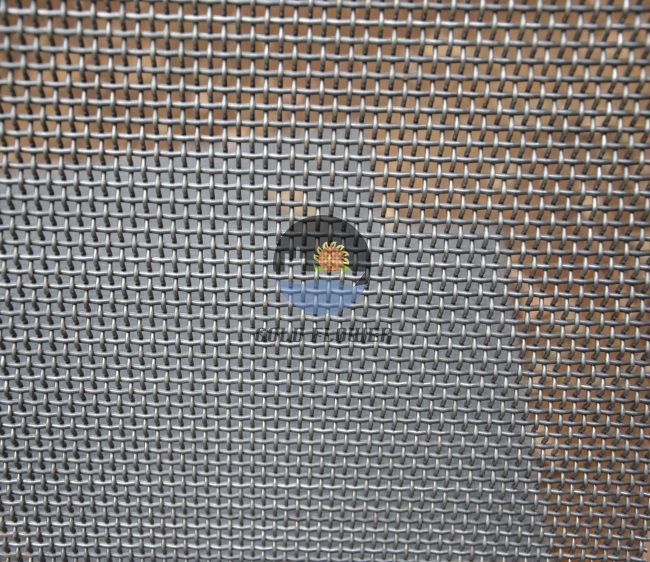

oem woven metal mesh fabric

Understanding the Versatility of OEM Woven Metal Mesh Fabric

In today's industrial landscape, the demand for durable and innovative materials continues to rise. One such material that has garnered significant attention is OEM woven metal mesh fabric. This versatile fabric is crafted from various metals, such as stainless steel, brass, and aluminum, woven together to create a strong yet flexible material that meets a wide range of applications across multiple industries.

OEM, or Original Equipment Manufacturer, highlights the customizable aspect of woven metal mesh fabric. Manufacturers can produce this material to meet specific requirements of their clients, tailoring the size, weave pattern, and metal type. This customization allows businesses to utilize woven metal mesh in ways that best suit their operational needs, resulting in improved performance and efficiency.

Understanding the Versatility of OEM Woven Metal Mesh Fabric

In the automotive industry, OEM woven metal mesh is employed in various components, including grills, filters, and soundproofing panels. The excellent durability of this material allows it to withstand harsh environmental conditions, including high temperatures and corrosive substances. This not only enhances the longevity of automotive parts but also contributes to improved safety and performance.

oem woven metal mesh fabric

The aerospace sector also benefits significantly from woven metal mesh fabric. It is often used in components that require both lightweight properties and high strength, such as in aircraft interiors and fuel filtration systems. The compatibility of woven metal with advanced manufacturing techniques, like 3D printing and CNC machining, enables the creation of complex structures that meet strict regulatory standards.

Another crucial application of woven metal mesh is in filtration systems. The fabric acts as a filter medium, effectively separating solids from liquids or gases. Its durability and resistance to clogging make it a preferred choice in industrial filtration and commercial applications, including water treatment, chemical processing, and food manufacturing. Customized mesh patterns can be designed to achieve specific filtration rates, thus enhancing the efficiency of the filtration process.

Moreover, the aesthetic appeal of woven metal mesh fabric can also enhance design in various sectors, including furniture, art installations, and interior design. Its sleek, modern look can impart a touch of sophistication while maintaining functionality, proving that practicality does not have to compromise style.

In conclusion, OEM woven metal mesh fabric represents a remarkable fusion of strength, versatility, and customization. As industries continue to evolve, the applications and innovations surrounding this material are expected to grow. By understanding the inherent properties of woven metal mesh and its various uses, manufacturers can not only improve their products but also contribute to the development of more sustainable and efficient solutions in their respective fields. Whether in construction, automotive, aerospace, or filtration, OEM woven metal mesh fabric stands out as a critical component of modern industrial design and engineering.

share

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025

-

CE Certification Buy Wire Mesh Fence for High Security and Durability

NewsJul.30,2025

-

Stainless Steel Mesh Filter Discs for Precise Filtration Solutions

NewsJul.29,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.29,2025