jan . 09, 2025 12:01 Back to list

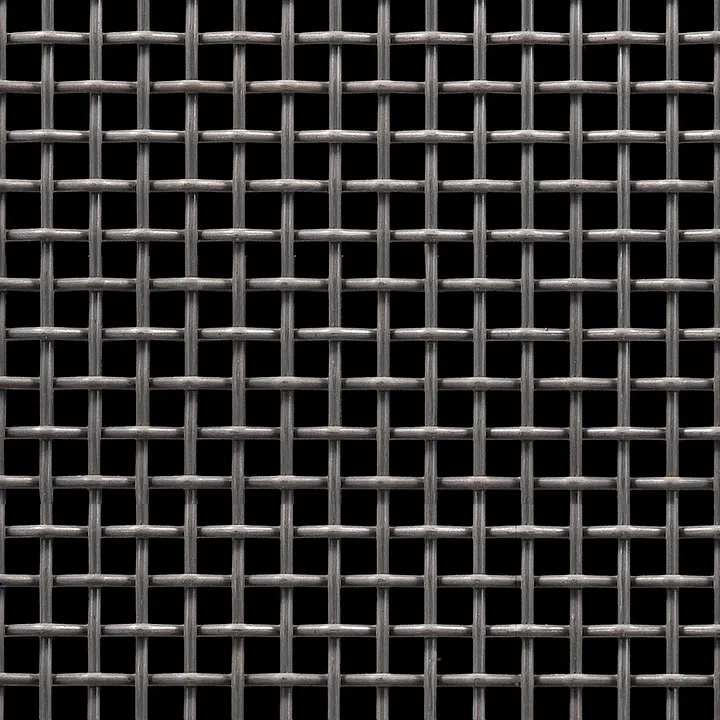

wire netting

Wire netting, commonly known as wire mesh or chicken wire, has transformed from a simple agricultural tool into a multifaceted product with applications spanning across various industries. As someone who has seen the evolution of wire netting, I can attest to its versatility and functionality.

Industrial applications of wire netting are broad and complex, covering areas such as filtration, where it ensures the separation of materials based on size. Its precision manufacturing allows for customized mesh sizes that meet specific filtration requirements across various sectors, from food processing to chemical production. The environmental benefits of wire netting cannot be overlooked. It aids in erosion control by stabilizing soil in places susceptible to land-slides or washouts after heavy rainfalls. This ecological application underscores the product’s versatility, contributing to sustainable practices and environmental conservation. Despite its widespread use, selecting the right type of wire netting is crucial. Considerations include the intended application, environmental conditions, and the required durability. Consulting with an expert ensures that the chosen product will meet the demands of your specific project while offering longevity and effectiveness. For those aiming to make sustainable choices, look for manufacturers who employ environmentally friendly practices in the production of wire netting. Recyclable materials and reduced carbon footprints in their processes contribute to broader sustainability goals. Trustworthy suppliers often provide certifications or evidence of their commitment to environmentally conscious production. Wire netting's reliability and multi-utility have established its presence across numerous fields. Its evolution from basic fencing to advanced structural support demonstrates its capacity to adapt to modern challenges and requirements. As more innovations arise, particularly with material sciences advancing, wire netting's capabilities and applications are bound to expand further, warranting its continued relevance and use. Choosing wire netting involves looking at not just current needs, but also anticipating future developments in the industry. It’s a product where a little research into materials, treatments, and applications can yield significant benefits, ensuring that its performance meets expectations in all conceivable scenarios.

Industrial applications of wire netting are broad and complex, covering areas such as filtration, where it ensures the separation of materials based on size. Its precision manufacturing allows for customized mesh sizes that meet specific filtration requirements across various sectors, from food processing to chemical production. The environmental benefits of wire netting cannot be overlooked. It aids in erosion control by stabilizing soil in places susceptible to land-slides or washouts after heavy rainfalls. This ecological application underscores the product’s versatility, contributing to sustainable practices and environmental conservation. Despite its widespread use, selecting the right type of wire netting is crucial. Considerations include the intended application, environmental conditions, and the required durability. Consulting with an expert ensures that the chosen product will meet the demands of your specific project while offering longevity and effectiveness. For those aiming to make sustainable choices, look for manufacturers who employ environmentally friendly practices in the production of wire netting. Recyclable materials and reduced carbon footprints in their processes contribute to broader sustainability goals. Trustworthy suppliers often provide certifications or evidence of their commitment to environmentally conscious production. Wire netting's reliability and multi-utility have established its presence across numerous fields. Its evolution from basic fencing to advanced structural support demonstrates its capacity to adapt to modern challenges and requirements. As more innovations arise, particularly with material sciences advancing, wire netting's capabilities and applications are bound to expand further, warranting its continued relevance and use. Choosing wire netting involves looking at not just current needs, but also anticipating future developments in the industry. It’s a product where a little research into materials, treatments, and applications can yield significant benefits, ensuring that its performance meets expectations in all conceivable scenarios.

share

Next:

Latest news

-

CE Certified 250 Micron Stainless Steel Mesh for Precision Filtration

NewsAug.22,2025

-

CE Certified 250 Micron SS Mesh - Precision Filtration & Strength

NewsAug.21,2025

-

CE Certified Woven Wire Mesh Filters | Premium Filtration Solutions

NewsAug.19,2025

-

High-Performance Particle Filters: Optimal Mediums & Applications

NewsAug.18,2025

-

Competitive Screen Mesh Price | 1/4", 1/8", 1/2" Wire Mesh Screens

NewsAug.17,2025

-

CE Certified 250 Micron SS Mesh: Precision & Durability

NewsAug.15,2025