sie . 20, 2024 21:24 Back to list

High-Quality OEM Stainless Steel 325 Mesh for Versatile Applications and Durability

OEM Stainless Steel 325 Mesh A Comprehensive Overview

In today's rapidly evolving manufacturing landscape, the demand for high-quality materials is more significant than ever. Among these materials, stainless steel meshes stand out due to their unique combination of durability, versatility, and resistance to corrosion. One specific variant, the OEM stainless steel 325 mesh, has gained considerable attention in various industries, including filtration, construction, and automotive.

What is Stainless Steel 325 Mesh?

Stainless steel 325 mesh refers to a particular type of woven wire mesh with a specified mesh count. The “325” indicates that there are 325 openings per square inch. This fine mesh structure allows for precise filtration and separation processes, making it ideal for applications requiring high levels of accuracy. Composed mainly of stainless steel, it exhibits excellent resistance to oxidation and corrosion, ensuring longevity and effectiveness even in harsh environments.

Key Features and Benefits

1. Corrosion Resistance One of the most significant advantages of stainless steel 325 mesh is its inherent resistance to rust and corrosion. Unlike ordinary steel, stainless steel contains chromium, which forms a protective layer on the surface. This feature makes it suitable for applications in humid or chemical-laden environments.

2. Durability The mesh is engineered to withstand high levels of stress and impact. Its robust structure ensures it retains its shape and functionality over time, which is crucial in industrial applications where equipment is subject to rigorous use.

3. High Filtration Efficiency The fine mesh openings of the 325 stainless steel mesh allow for efficient filtration of small particles. This capability is essential in industries like pharmaceuticals, food processing, and water treatment, where purity and quality are paramount.

4. OEM Customization OEM (Original Equipment Manufacturer) stainless steel 325 mesh can be customized to meet specific requirements. Manufacturers can adjust the width, length, and even the properties of the mesh, ensuring it fits the unique needs of different applications. This flexibility is particularly advantageous for industries that require specialized materials.

oem stainless steel 325 mesh

5. Ease of Maintenance Stainless steel mesh is relatively low maintenance. Its smooth surface allows for easy cleaning, making it a preferred choice in industries where hygiene is critical, such as food and beverage production.

Applications of Stainless Steel 325 Mesh

The applications of OEM stainless steel 325 mesh are diverse and span several industries

- Filtration Used in various filtration systems, including water filters, air filters, and industrial filtration processes. The precision and durability of 325 mesh make it ideal for applications requiring high performance and reliability.

- Construction In the construction industry, stainless steel mesh is utilized for reinforcing concrete, protecting structures, and in architectural applications. Its strength and aesthetic appeal make it a favorable choice.

- Automotive In the automotive sector, it is employed in catalytic converters and other emission control devices, where its ability to withstand high temperatures and corrosive environments is critical.

- Electronics The electronics industry uses stainless steel mesh for EMI shielding and RFI shielding, helping to protect sensitive components from electromagnetic interference.

Conclusion

OEM stainless steel 325 mesh is a vital material that combines strength, versatility, and durability, making it indispensable in various industrial applications. Its ability to resist corrosion and maintain structural integrity under stress further reinforces its role in modern manufacturing. As industries continue to prioritize efficiency and quality, the significance of such materials will only continue to grow, ensuring that stainless steel 325 mesh remains at the forefront of innovative solutions. Whether for filtration, construction, or automotive applications, the benefits of this mesh are profound, standing as a testament to the advancements in material science and engineering.

share

-

High-Quality Screen Stone for Modern Stone Screen Walls Elegant Facade Solutions

NewsJun.10,2025

-

High Quality Wire Filter – Cheap Stainless Steel Filter Wire Mesh Cloth & Wire Mesh Filter Solutions

NewsJun.10,2025

-

5 Micron Water Filter Cartridge - Premium Sediment Filtration, Universal Fit

NewsJun.10,2025

-

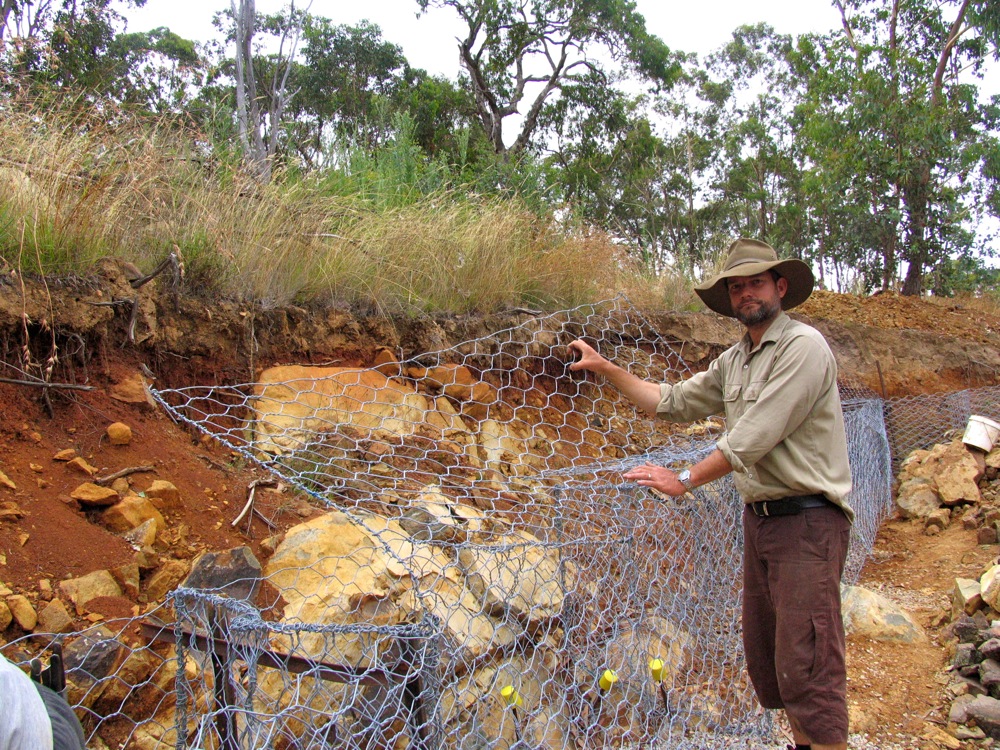

High Quality CE-Certified Gabion Boxes with OEM Options

NewsJun.10,2025

-

20x20x2 Air Filter High-Efficiency Dust Filtration for Clean Air

NewsJun.10,2025

-

Decorative Metal Mesh for Radiator Covers Custom Durable Mesh Panels

NewsJun.10,2025