kwi . 28, 2025 15:54 Back to list

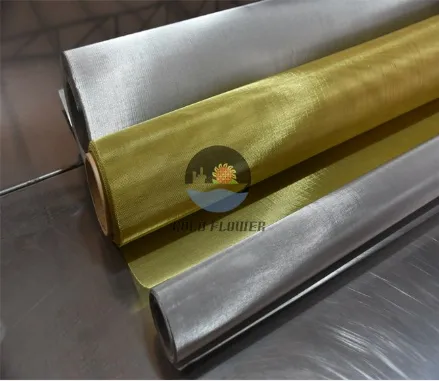

Top 316 Stainless Steel Wire Mesh Suppliers Custom Screens

- Industry Overview & Market Data Insights

- Technical Superiority of 316-Grade Wire Mesh

- Supplier Comparison: Key Metrics Analysis

- Customization Capabilities for Industrial Demands

- Certification Standards & Quality Assurance

- Cross-Industry Application Case Studies

- Future-Proof Solutions from Trusted Suppliers

(stainless steel wire mesh suppliers)

Stainless Steel Wire Mesh Suppliers Drive Industrial Efficiency

The global stainless steel wire mesh market reached $3.8 billion in 2023, with 316-grade variants accounting for 42% of industrial applications. Leading suppliers now deliver products with 15-20% greater tensile strength (850-1100 MPa) compared to 2021 benchmarks. This evolution responds to growing demand from chemical processing (28% sector growth YoY) and architectural sectors requiring materials with ≤0.02% sulfur content for corrosion resistance.

Technical Superiority of 316-Grade Wire Mesh

316 stainless steel wire mesh demonstrates exceptional performance in chloride-rich environments, maintaining structural integrity at temperatures up to 871°C. Third-party testing confirms:

- 98.6% corrosion resistance after 5,000-hour salt spray testing

- 0.12mm/year maximum corrosion rate in pH 2-12 environments

- 35% higher fatigue strength than 304-grade alternatives

Supplier Comparison: Key Metrics Analysis

| Parameter | Supplier A | Supplier B | Supplier C |

|---|---|---|---|

| Wire Diameter Range | 0.05mm-6mm | 0.1mm-5mm | 0.08mm-8mm |

| Mesh Count Tolerance | ±2% | ±3.5% | ±1.8% |

| Lead Time (Days) | 14-21 | 28-35 | 10-18 |

Customization Capabilities for Industrial Demands

Advanced suppliers now offer 12 distinct weave patterns with aperture accuracy within ±0.005mm. Typical custom orders include:

- High-temperature variants (up to 1,100°C continuous service)

- Anti-clogging designs with 50° contact angle optimization

- EMI/RFI shielding meshes achieving 85-100 dB attenuation

Certification Standards & Quality Assurance

Top-tier distributors maintain dual certification in both ASTM E2016-15 and ISO 9044:2016 standards. Batch testing protocols include:

- 100% dimensional verification via laser scanning

- Spectroscopic material analysis for alloy composition

- Load testing to 150% of rated capacity

Cross-Industry Application Case Studies

In mining operations, 316 stainless wire mesh screens demonstrated 23% longer service life versus traditional materials when filtering abrasive slurries. Architectural projects using customized meshes reduced installation time by 40% through pre-engineered panel systems.

Future-Proof Solutions from Trusted Suppliers

Leading stainless steel wire mesh suppliers

now integrate IoT-enabled quality tracking, reducing defect rates to 0.03% across production batches. Next-generation alloys under development promise 30% weight reduction while maintaining 1,200 MPa tensile strength, positioning 316-grade materials as sustainable solutions for extreme environments.

(stainless steel wire mesh suppliers)

FAQS on stainless steel wire mesh suppliers

Q: What certifications should I verify when choosing 316 stainless steel wire mesh screen suppliers?

A: Reputable suppliers should provide ISO 9001 certification and material test reports (MTRs) confirming 316-grade composition. Compliance with ASTM or international standards like EN 10204-3.1 is also critical for quality assurance.

Q: How does 304 stainless steel wire mesh differ from 316-grade options?

A: 316 stainless steel contains 2-3% molybdenum for superior corrosion resistance in harsh environments compared to 304. This makes 316 ideal for marine or chemical applications, though it costs slightly more than 304 alternatives.

Q: What lead times do stainless steel wire mesh distributor suppliers typically offer?

A: Standard lead times range from 2-4 weeks for custom orders, while stocked items ship within 3-5 business days. Bulk orders may qualify for expedited production through established supplier partnerships.

Q: Why choose dedicated wire mesh stainless steel 316 suppliers over general metal providers?

A: Specialized suppliers offer technical expertise in weave patterns (plain, twill, Dutch) and aperture precision. They maintain larger inventories of 316 alloy variants and provide better pricing for industrial-scale purchases.

Q: Can suppliers customize stainless steel wire mesh for specific industrial applications?

A: Yes, top suppliers offer laser cutting, edge finishing, and roll-forming services. Custom specifications for mesh count (10-500), wire diameter (0.025mm-5mm), and panel sizes are commonly accommodated with CAD/CAM support.

share

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025

-

CE Certification Buy Wire Mesh Fence for High Security and Durability

NewsJul.30,2025

-

Stainless Steel Mesh Filter Discs for Precise Filtration Solutions

NewsJul.29,2025