Фев . 13, 2025 04:07 Back to list

Filtering Mesh Packs

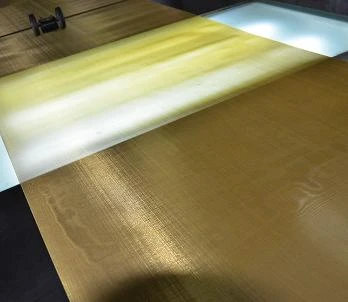

Acquiring round wire mesh screens can significantly enhance various projects, whether you're involved in industrial, commercial, or DIY tasks. Selecting the right wire mesh screens for your particular application is crucial for ensuring durability, efficiency, and cost-effectiveness. An expert understanding of different material types, weave patterns, and specifications can guide your purchase decision, elevating both the quality and productivity of your work.

Fabrication and installation expertise add another layer of authority and trustworthiness to your choice of wire mesh screen. Custom fabrication options, such as cutting, welding, and forming, allow for precise fitting and adaptability to various applications, including enclosures, guards, grilles, and sieves. Ensuring proper installation by adhering to manufacturer guidelines and utilizing professional assistance when necessary ensures the longevity and maximum performance of the wire mesh screens. Adopting wire mesh screens in your industrial or commercial processes provides ample opportunity for optimization. For instance, in agricultural settings, round wire mesh screens can protect crops from pests while allowing sufficient airflow and sunlight. In architectural applications, they can function as both protective and aesthetic elements, offering security without compromising beauty. Purchasing round wire mesh screens involves not only understanding your immediate project needs but also considering long-term demands like maintenance and potential future applications. Selecting the right supplier who offers not just quality products but excellent customer service and support can make a significant difference in outcome success. Finally, staying informed about cutting-edge trends in the wire mesh industry can further enhance your decision-making process. Emerging technologies in material science, such as self-cleaning coatings and enhanced anti-corrosive materials, can extend the functionality and lifespan of wire mesh products, ensuring that your investment remains effective for years to come. In conclusion, a comprehensive understanding of your project requirements, coupled with industry expertise and a trusted supplier, positions you for success when you buy round wire mesh screens. With thoughtful selection and application, wire mesh screens are a cornerstone in the advancement and sustainability of your business operations.

Fabrication and installation expertise add another layer of authority and trustworthiness to your choice of wire mesh screen. Custom fabrication options, such as cutting, welding, and forming, allow for precise fitting and adaptability to various applications, including enclosures, guards, grilles, and sieves. Ensuring proper installation by adhering to manufacturer guidelines and utilizing professional assistance when necessary ensures the longevity and maximum performance of the wire mesh screens. Adopting wire mesh screens in your industrial or commercial processes provides ample opportunity for optimization. For instance, in agricultural settings, round wire mesh screens can protect crops from pests while allowing sufficient airflow and sunlight. In architectural applications, they can function as both protective and aesthetic elements, offering security without compromising beauty. Purchasing round wire mesh screens involves not only understanding your immediate project needs but also considering long-term demands like maintenance and potential future applications. Selecting the right supplier who offers not just quality products but excellent customer service and support can make a significant difference in outcome success. Finally, staying informed about cutting-edge trends in the wire mesh industry can further enhance your decision-making process. Emerging technologies in material science, such as self-cleaning coatings and enhanced anti-corrosive materials, can extend the functionality and lifespan of wire mesh products, ensuring that your investment remains effective for years to come. In conclusion, a comprehensive understanding of your project requirements, coupled with industry expertise and a trusted supplier, positions you for success when you buy round wire mesh screens. With thoughtful selection and application, wire mesh screens are a cornerstone in the advancement and sustainability of your business operations.

share

Next:

Latest news

-

CE Certified 250 Micron Stainless Steel Mesh Filter

NewsAug.04,2025

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025