Фев . 12, 2025 23:33 Back to list

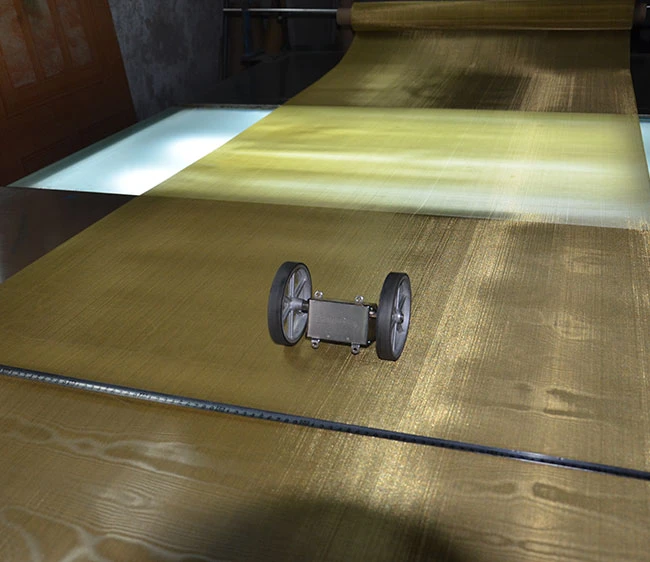

woven filter mesh

Stainless steel woven mesh is an incredibly versatile and durable material that finds its use in a variety of applications, from industrial to architectural designs. One of the key advantages of choosing stainless steel woven mesh is its outstanding resilience and longevity, providing significant benefits to industries that require robust materials.

Trustworthiness is paramount when purchasing stainless steel woven mesh, as inferior quality materials can lead to catastrophic failures in critical applications. Reputable suppliers and manufacturers consistently provide certifications and quality guarantees, detailing the material's specifications and compliance with industry standards. Buyers can usually verify these credentials, adding a layer of security and peace of mind. Furthermore, the global shift toward sustainable materials has put stainless steel woven mesh in a favorable position. Stainless steel is 100% recyclable, making it a sustainable choice for eco-friendly construction and industrial practices. This feature not only supports the growing demand for green materials but also aligns with corporate responsibilities towards sustainable development. In terms of maintenance, stainless steel woven mesh is relatively low-effort compared to other materials. Its resistance to rust and corrosion means that it requires less frequent maintenance, translating to reduced long-term costs. Regular cleaning is often enough to maintain its optimal appearance and performance, an attribute that is invaluable to both industrial users and architects. Finally, the choice of supplier is a critical decision when buying stainless steel woven mesh. Conducting thorough research and selecting a supplier with a proven track record of excellence and customer satisfaction is imperative. Reviews and testimonials from other buyers can provide invaluable insights into the supplier's reliability and product quality. Overall, stainless steel woven mesh stands out as a top choice for industries and architects seeking durable, aesthetically pleasing, and environmentally friendly materials. Its unmatched versatility and enduring performance attest to its rising popularity across various sectors, confirming its position as a staple material in modern industry and design.

Trustworthiness is paramount when purchasing stainless steel woven mesh, as inferior quality materials can lead to catastrophic failures in critical applications. Reputable suppliers and manufacturers consistently provide certifications and quality guarantees, detailing the material's specifications and compliance with industry standards. Buyers can usually verify these credentials, adding a layer of security and peace of mind. Furthermore, the global shift toward sustainable materials has put stainless steel woven mesh in a favorable position. Stainless steel is 100% recyclable, making it a sustainable choice for eco-friendly construction and industrial practices. This feature not only supports the growing demand for green materials but also aligns with corporate responsibilities towards sustainable development. In terms of maintenance, stainless steel woven mesh is relatively low-effort compared to other materials. Its resistance to rust and corrosion means that it requires less frequent maintenance, translating to reduced long-term costs. Regular cleaning is often enough to maintain its optimal appearance and performance, an attribute that is invaluable to both industrial users and architects. Finally, the choice of supplier is a critical decision when buying stainless steel woven mesh. Conducting thorough research and selecting a supplier with a proven track record of excellence and customer satisfaction is imperative. Reviews and testimonials from other buyers can provide invaluable insights into the supplier's reliability and product quality. Overall, stainless steel woven mesh stands out as a top choice for industries and architects seeking durable, aesthetically pleasing, and environmentally friendly materials. Its unmatched versatility and enduring performance attest to its rising popularity across various sectors, confirming its position as a staple material in modern industry and design.

share

Latest news

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.22,2025

-

CE Certified 250 Micron Stain Steel Mesh - Durable & Safe

NewsJul.21,2025

-

CE Certified 250 Micron Stainless Steel Mesh - High Durability & CE Approved

NewsJul.21,2025

-

Premium Slope Collapse Protection Mesh | Durable & Effective

NewsJul.20,2025

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025