Дек . 29, 2024 15:16 Back to list

ce certification fine stainless mesh

Understanding CE Certification for Fine Stainless Steel Mesh

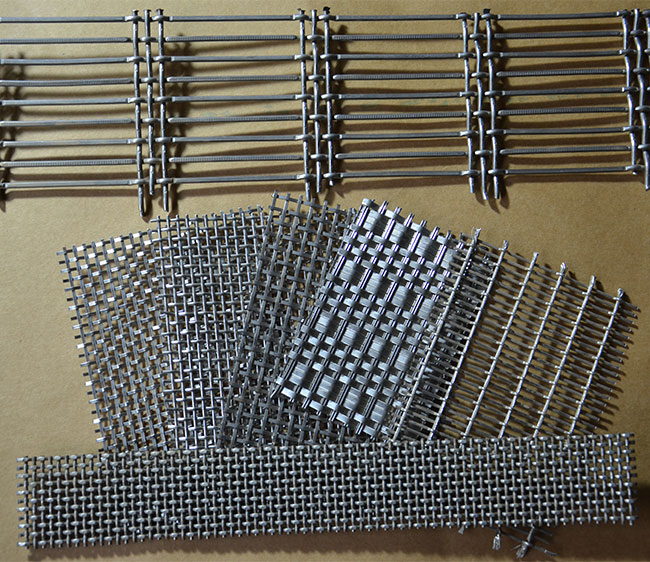

In today’s global marketplace, the demand for high-quality materials continues to rise, particularly in industries such as construction, manufacturing, and filtration. One such material that has gained considerable attention is fine stainless steel mesh. This versatile product is renowned for its durability, aesthetic appeal, and functional properties. However, for manufacturers and distributors, achieving CE certification can be a significant endeavor that enhances the product's credibility and marketability.

What is CE Certification?

CE marking is a certification that indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA). It serves as an assurance that the product meets EU regulatory requirements and is safe for use. For fine stainless steel mesh, CE certification is crucial, especially for applications in sectors that require stringent safety measures, such as food and beverage processing, pharmaceuticals, and construction.

Importance of Fine Stainless Steel Mesh

Fine stainless steel mesh is extensively used for various applications due to its unique characteristics. It is resistant to corrosion, can withstand high temperatures, and has excellent mechanical properties. These attributes make it ideal for use in filtration systems, safety screens, and architectural applications. The mesh is also favored for its hygienic properties, making it suitable for food contact applications. However, the absence of CE certification can severely limit its acceptance in the market, especially in Europe.

The CE Certification Process

Achieving CE certification for fine stainless steel mesh involves several key steps, ensuring that the product meets all necessary standards. Manufacturers must conduct a thorough risk assessment and determine the applicable EU directives. Among the most relevant directives for stainless steel mesh are the Machinery Directive, the Low Voltage Directive, and the RoHS Directive concerning hazardous substances.

1. Product Testing The mesh must undergo rigorous testing to evaluate its strength, durability, and safety features. Testing may include tensile strength tests, corrosion resistance tests, and assessments for hygienic properties, depending on the intended application.

ce certification fine stainless mesh

2. Technical Documentation Manufacturers need to compile comprehensive technical documentation that details the design, manufacturing process, and use of the product. This documentation is essential not only for compliance but also for future audits.

3. Declaration of Conformity Once the product passes all necessary tests and meets the requirements, the manufacturer must create a Declaration of Conformity. This document states that the product complies with all applicable EU directives and regulations.

4. CE Marking After successfully completing the above steps, the final stage is to affix the CE marking to the product. This marking must be visible, legible, and permanently attached to the mesh or its packaging.

Benefits of CE Certification for Fine Stainless Steel Mesh

1. Market Access CE certification opens the door to the European market, allowing manufacturers to sell their products without facing additional barriers.

2. Trust and Credibility Obtaining CE certification enhances the reputation of the manufacturer. Clients and customers are more likely to trust products that have been certified, knowing they meet rigorous standards.

3. Legal Protection Compliance with CE requirements can protect manufacturers from potential legal issues. In the event of a product failure or safety concern, having CE certification can serve as evidence that due diligence was exercised.

Conclusion

In conclusion, CE certification is an essential step for manufacturers of fine stainless steel mesh who wish to compete in the global market, particularly within the European Union. With its numerous applications and benefits, ensuring that these products are certified is not just about compliance; it is about delivering quality and safety to end users. As industries continue to evolve, the importance of maintaining high standards will only grow, making CE certification a critical consideration for manufacturers aiming for success in today’s competitive landscape.

share

-

Decorative Brass Mesh: Elevate Interiors with Timeless Elegance

NewsAug.08,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Precision & Durability

NewsAug.07,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Fine & Durable

NewsAug.06,2025

-

CE Certified 250 Micron Stainless Steel Mesh Filter

NewsAug.04,2025

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025