Ноя . 22, 2024 00:51 Back to list

filter element price

Understanding Filter Element Price Factors and Implications

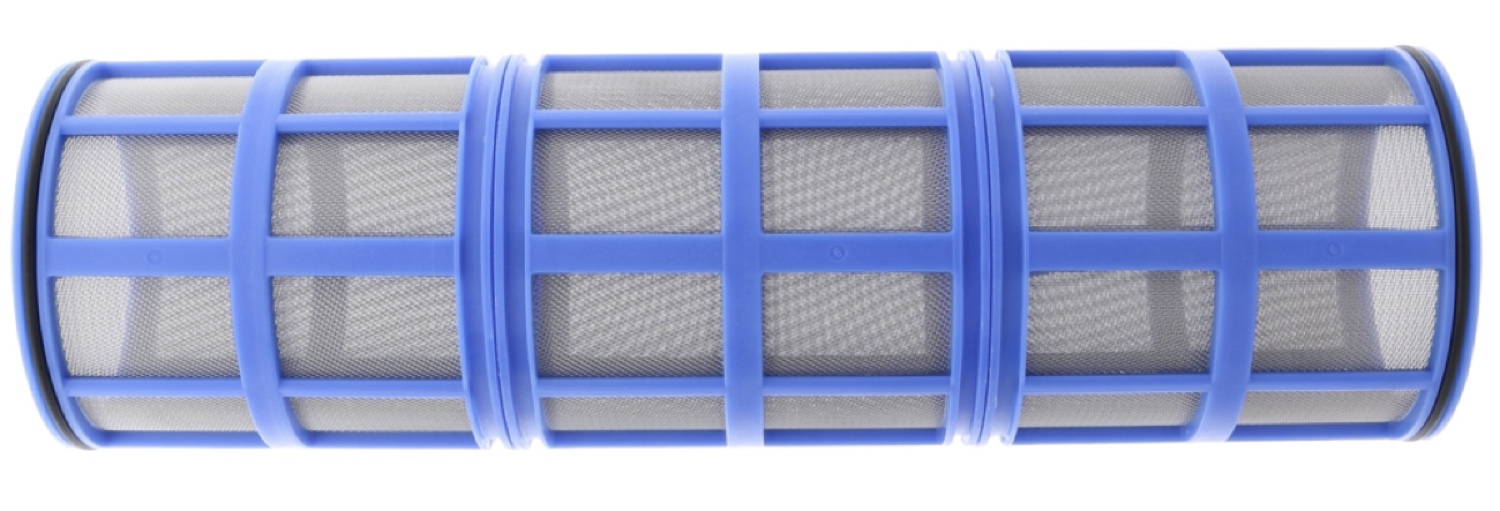

In the world of industrial filtration, the filter element price plays a crucial role in influencing not only operational costs but also the overall efficiency and longevity of filtration systems

. As industries strive for higher efficiency and lower operational costs, understanding the factors that contribute to the pricing of filter elements becomes increasingly important.Filter elements are critical components in various filtration systems, ranging from water treatment plants to industrial manufacturing. They are designed to remove impurities and contaminants from fluids, ensuring that processes run smoothly and that end products meet safety and quality standards. The price of filter elements can vary significantly based on several key factors.

1. Material Composition The material used in manufacturing filter elements greatly affects their cost. Common materials include cellulose, fiberglass, and synthetic fibers, each with its unique properties and price points. For instance, filters made from high-performance synthetic materials tend to be more expensive than those made from traditional cellulose due to their superior filtration efficiency and durability. Businesses must weigh the upfront costs of more expensive filters against their potential to provide longer service life and lower maintenance expenses.

2. Filtration Efficiency The filtration efficiency of an element significantly impacts its price. Higher efficiency filters, which can capture smaller particles, often come at a premium. This is due to the advanced technology and research that goes into their production. Industries that require high levels of cleanliness, such as pharmaceuticals and food processing, are often willing to invest in more expensive filter elements to avoid contamination and compliance issues.

filter element price

3. Brand and Quality Not all filters are created equal. Established brands with a reputation for quality and reliability may charge more for their products. This is often justified by the extensive testing, research, and customer support they provide. Conversely, cheaper, generic options might save money initially but could lead to increased costs in the long run due to frequent replacements and potential operational disruptions.

4. Volume and Customization Bulk purchases can lead to significant discounts in filter element pricing. Additionally, customized filters designed to meet specific operational requirements may incur additional costs. While customization may seem expensive initially, tailored filters can provide better performance and longevity, ultimately saving money.

5. Market Conditions The global market dynamics also play a role in filter element pricing. Supply chain issues, material scarcity, and fluctuations in demand can cause prices to rise. Moreover, economic factors and trade policies can impact the cost of raw materials, influencing the final price of filter elements.

In conclusion, understanding filter element price requires a comprehensive examination of various factors such as material composition, filtration efficiency, brand reputation, customization, and market conditions. Businesses must carefully evaluate these aspects to make informed decisions that align with their operational needs and budget constraints. While opting for the cheapest option may be tempting, investing in higher-quality filter elements can lead to better long-term performance and cost savings, emphasizing the importance of a strategic approach to filtration expenditures.

share

-

High-Quality Screen Stone for Modern Stone Screen Walls Elegant Facade Solutions

NewsJun.10,2025

-

High Quality Wire Filter – Cheap Stainless Steel Filter Wire Mesh Cloth & Wire Mesh Filter Solutions

NewsJun.10,2025

-

5 Micron Water Filter Cartridge - Premium Sediment Filtration, Universal Fit

NewsJun.10,2025

-

High Quality CE-Certified Gabion Boxes with OEM Options

NewsJun.10,2025

-

20x20x2 Air Filter High-Efficiency Dust Filtration for Clean Air

NewsJun.10,2025

-

Decorative Metal Mesh for Radiator Covers Custom Durable Mesh Panels

NewsJun.10,2025