Дек . 01, 2024 08:46 Back to list

Optimizing ODM Wire Mesh Length for Efficient Production and Application

Exploring ODM Wire Mesh Length Applications and Considerations

Wire mesh materials, particularly those manufactured by Original Design Manufacturers (ODMs), have become increasingly vital in various industries. Among the many factors to consider when using wire mesh, the length of the material plays a crucial role in determining its suitability for specific applications. This article delves into the significance of ODM wire mesh length, its implications for different sectors, and key considerations when selecting the right dimensions for your needs.

Understanding ODM Wire Mesh

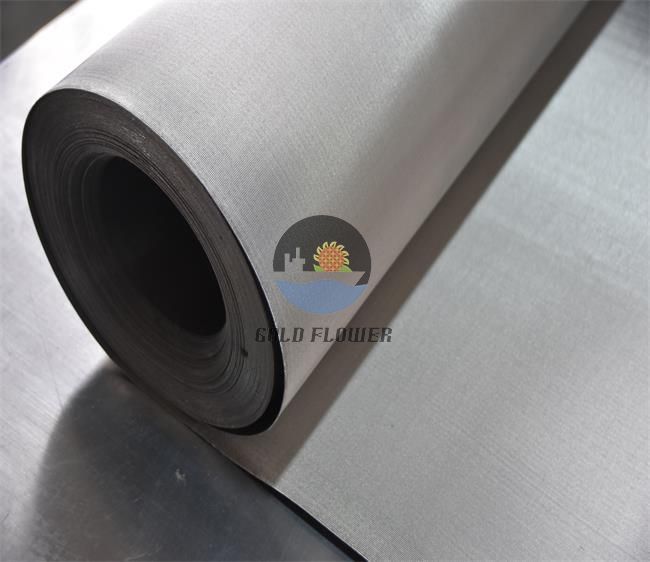

Before we dive into the specifics of length, it's essential to grasp what ODM wire mesh entails. ODM refers to manufacturers who design and produce products based on the specifications laid out by their clients. Wire mesh is a versatile material made from interconnected wires that can be crafted into various shapes and sizes. The wire mesh can be made from material such as stainless steel, aluminum, or plastic, each offering distinct characteristics tailored for particular uses.

The Importance of Wire Mesh Length

The length of wire mesh is often dictated by the intended application. Whether it's used in construction, filtration, fencing, or decorative purposes, an understanding of the required dimensions is crucial for practical use.

1. Construction Applications In building and construction, wire mesh is commonly used for reinforcement in concrete structures. Here, the length of the mesh must align with the dimensions of the area being reinforced. If the length is insufficient, it can lead to structural weaknesses, potentially jeopardizing safety and performance. Additionally, longer meshes contribute to fewer seams and joints, which means fewer points of potential failure.

2. Filtration Systems In sectors such as food and beverage processing, wire mesh is utilized for filtration. The length of the mesh affects the surface area available for filtration, making it a critical factor in the efficiency of the system. An appropriately sized mesh can enhance the filtration process, while an incorrect length could lead to clogs or insufficient filtration.

3. Fencing and Security In security applications, wire mesh is often employed in fencing solutions. The length of the wire mesh panels must be adequate to cover the desired area without gaps. Too short a panel may compromise security, while overly long panels can be wasteful and challenging to install.

odm wire mesh length

4. Architectural Design In contemporary architecture, wire mesh is used as a decorative feature in facades or interior design. Here, the length can be a crucial element in achieving the desired aesthetic while ensuring structural integrity. Custom lengths may be needed to fit unique designs, demonstrating why working with ODMs can be beneficial for precise requirements.

Key Considerations When Selecting Length

When selecting ODM wire mesh length, several factors should be taken into account to ensure optimal performance

- Application Needs Assess the specific needs of your project. Whether for construction, filtration, fencing, or design, understanding the requirements helps guide your selection.

- Material Specifications Different materials have various properties that affect the performance of wire mesh. Understanding how wire length interacts with the specific material can influence your choice.

- Regulatory Standards Certain applications, especially in construction and food processing, may have regulatory standards that dictate dimensions. Ensuring compliance can save time and debt down the line.

- Custom Manufacturing Working with ODMs allows for custom lengths tailored to your project's specifications. This flexibility can be especially beneficial in unique projects requiring non-standard sizes.

Conclusion

In conclusion, the length of ODM wire mesh is of paramount importance for ensuring its effectiveness across diverse applications. By understanding the specific requirements of each use case and collaborating with manufacturers that specialize in custom solutions, businesses can optimize their operations and ensure safety, efficiency, and aesthetics. As industries continue to evolve, the demand for high-quality, appropriately sized wire mesh will only grow, making careful consideration of length all the more vital.

share

-

CE Certified 250 Micron Stainless Steel Mesh | Precision & Durability

NewsAug.27,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision & Durability

NewsAug.26,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision & Durability

NewsAug.25,2025

-

Premium CE Certified Metal Fine Mesh for Precision & Safety

NewsAug.24,2025

-

Stainless Steel Wedge Wire Mesh: Durable, Precision Filtration

NewsAug.23,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision Filtration

NewsAug.22,2025