Окт . 31, 2024 23:06 Back to list

OEM 1 8 Screen Mesh Specifications and Applications in Industrial Settings

Understanding OEM 1 8 Screen Mesh A Key Component in Industrial Applications

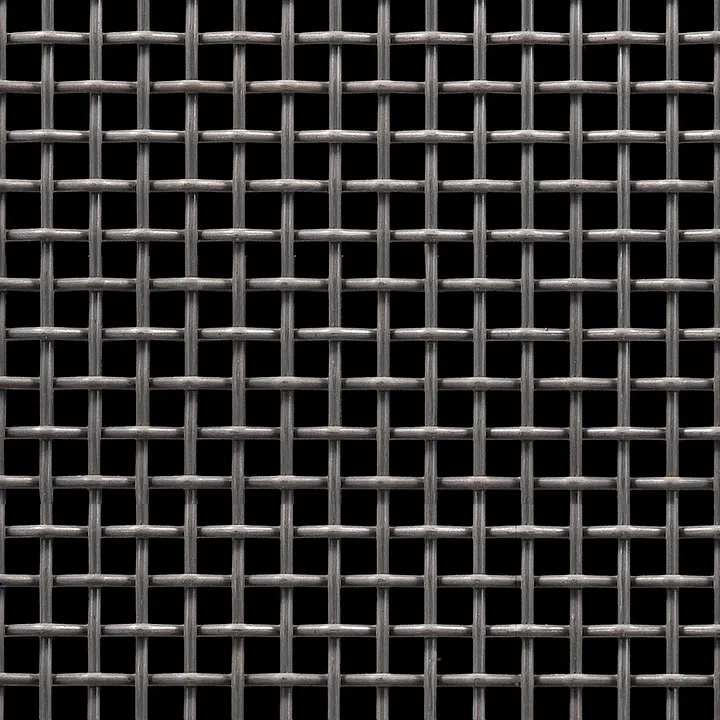

In today's fast-paced industrial landscape, efficiency and precision are paramount. One of the unsung heroes in this quest for operational excellence is screen mesh, particularly the OEM 1 8 screen mesh. This versatile component serves several critical functions across a variety of sectors, including manufacturing, agriculture, and mining.

OEM, or Original Equipment Manufacturer, indicates that the screen mesh is produced by a company that designs and incorporates its products into another company’s end product. The 1 8 in the name likely refers to the specific mesh size or configuration, which dictates its applications and effectiveness in different settings.

Understanding OEM 1 8 Screen Mesh A Key Component in Industrial Applications

One of the primary applications for OEM 1 8 screen mesh is in the mining industry, where it is used for sieving and classifying ore materials. The mesh assists in removing smaller particles from larger fragments, thereby enhancing the efficiency of the extraction process. By utilizing the appropriate screen mesh, mining operations can streamline their processes, reduce waste, and improve yield.

oem 1 8 screen mesh

In agriculture, the OEM 1 8 screen mesh finds its significance in equipment such as seed cleaners and grain separators. Farmers and agricultural producers rely on this mesh to ensure the purity of their seeds and the quality of their harvest. By separating unwanted debris from crops, the screen significantly improves the overall quality and marketability of agricultural products.

The manufacturing industry also benefits from OEM 1 8 screen mesh in various processes, including filtration systems, where it is employed to filter out particles from liquids and gases. This is essential in industries such as food processing, pharmaceuticals, and chemical manufacturing, where cleanliness and contamination control are critical. The use of the right mesh can prevent costly errors and maintain product integrity, ensuring compliance with health and safety regulations.

Moreover, durability is a key attribute of quality screen meshes, including the OEM 1 8 variant. Often made from high-grade stainless steel or other resilient materials, the screen mesh is designed to withstand harsh environments and heavy workload. This longevity translates to reduced downtime and maintenance costs for businesses, providing a sound return on investment.

In conclusion, the OEM 1 8 screen mesh is not merely a component but a vital tool that enhances efficiency and effectiveness in various industrial applications. Its broad applicability—from mining to agriculture and manufacturing—demonstrates its versatility and importance in the operational processes that drive today’s economy. As industries continue to evolve and face new challenges, components like the OEM 1 8 screen mesh will remain crucial in achieving operational excellence and innovation. Understanding and implementing the right screen mesh can lead to significant improvements in productivity and product quality, highlighting its value in the modern industrial ecosystem.

share

-

CE Certified 250 Micron Stainless Steel Mesh Filter

NewsAug.04,2025

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025