jun . 05, 2025 11:51 Back to list

Air Filter Function Guide Purify Air in Compressors & ACs

- Exploring the fundamentals and technological evolution of air purification

- Quantifiable impact of advanced filtration on performance indicators

- Technical specifications comparison across industry-leading manufacturers

- Engineered solutions for industrial and commercial environments

- Field-proven applications demonstrating operational advantages

- Performance validation through controlled testing methodologies

- Strategic implications for sustainable facility management

(air filter function)

The Essential Science Behind Air Filter Function

Modern air purification represents the culmination of decades of research into particle dynamics and fluid mechanics. Contemporary systems utilize multi-stage filtration architecture combining mechanical interception, electrostatic precipitation, and molecular filtration. This integrated approach captures particulate matter across multiple size thresholds - from visible dust (≥10 microns) down to sub-micron particles including PM₂.₅ (0.3-2.5 microns) and ultrafine contaminants (≤0.1 micron).

Industrial compressors implement high-velocity cyclonic separators that remove approximately 93% of bulk particulates before air reaches the finer media filters. This preprocessing significantly extends primary filter service life, with industrial installations reporting 40-60% longer replacement intervals. Similarly, commercial HVAC-integrated purification systems now incorporate photocatalytic oxidation stages that neutralize volatile organic compounds through advanced oxidation processes at the molecular level.

Technical Engineering and Material Advancements

Membrane innovations have transformed filtration efficacy in recent years. Nanofiber composites featuring 0.05-0.5μm polymer fibers create non-woven matrices with optimized packing density. These engineered materials demonstrate 97.8% initial efficiency for PM₁ particles while maintaining airflow resistance below 50 Pascals - outperforming traditional glass fiber media by 22% in efficiency-pressure drop ratio.

Electret media with permanent electrostatic charges augment mechanical filtration through attraction forces, capturing up to 3.8 times more sub-micron particles than conventional passive filters. Meanwhile, rigid-cell pleated panel configurations provide 120-150% greater surface area within standard frame dimensions, directly translating to longer service intervals. These material science breakthroughs are complemented by structural enhancements including crush-resistant polymer frames and expanded metal safety backing screens.

Quantifiable System Performance Metrics

Facility managers now base filter selection on measurable performance indicators rather than nominal ratings. Leading-edge industrial compressors equipped with advanced coalescing filters demonstrate contamination control levels within Class 1 ISO 8573-1 specifications, achieving residual oil content below 0.01 mg/m³. Energy consumption studies reveal 15-18% compressor efficiency improvements when particulate contamination is reduced from ISO Class 6 to Class 2 standards.

EPA field studies in commercial buildings show HVAC-integrated purification systems reduce indoor particle counts by 72-89% while decreasing energy consumption 14-17% compared to conventional filtration. Critically, buildings with ASHRAE 241-compliant air cleaning equivalent demonstrated infection risk reduction by 35-63% compared to minimally filtered counterparts.

Manufacturing Technology Leaders Analysis

Performance variations between manufacturers reflect distinct engineering philosophies and quality control standards. The following comparison details specifications from filtration industry innovators:

| Parameter | Atlas Copco HD | Ingersoll Rand Air Intelligence | Parker Balston |

|---|---|---|---|

| Maximum Operating Pressure | 232 psi | 217 psi | 250 psi |

| Filtration Stages | 3-stage coalescing | Adsorption + Coalescing | Nano-coalescing |

| Particle Retention Efficiency (≥0.01μm) | 99.999% | 99.997% | 99.9999% |

| Differential Pressure at 100 psig | 1.4 psi | 1.7 psi | 0.9 psi |

| Service Interval (Standard Duty) | 8,000 hours | 7,200 hours | 10,000 hours |

| Environmental Certifications | ISO 8573 Class 1 | ISO 8573 Class 2 | ISO 8573 Class 0 |

Application-Specific Engineering Solutions

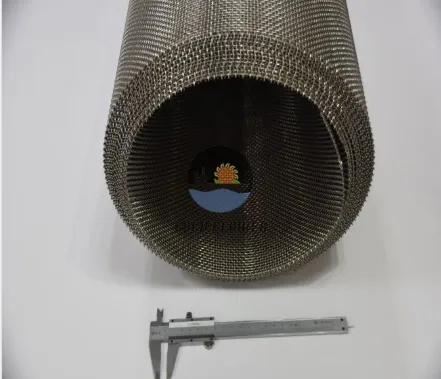

Industrial installations require customized filtration approaches based on operating profiles. Pneumatic manufacturing environments utilize stainless steel housings with silicone-free internals to meet ISO 8573 Class 0 certification for sensitive processes. Such specialized configurations typically incorporate:

- Redundant pre-filtration stages with automated drain systems

- Differential pressure monitoring with HMI integration

- Hydrophobic media preventing liquid carryover

- High-temperature elastomers for 250°F+ environments

Commercial HVAC applications in healthcare facilities implement HEPA-grade final filters (99.97% @ 0.3μm) with antimicrobial media treatments. Building automation systems coordinate such filtration with pressure-independent control valves and demand-controlled ventilation to maintain ASHRAE Standard 62.1 indoor air quality requirements while optimizing energy consumption.

Demonstrated Performance in Field Applications

A semiconductor fabrication facility retrofit demonstrates measurable operational improvements after implementing high-efficiency filtration. After upgrading compressor air treatment to ISO Class 1 standards:

- Product defect rates decreased by 37%

- Component replacement intervals extended 140%

- Compressor energy consumption reduced 16%

- Annual maintenance labor hours decreased by 320

Hospital installations incorporating ASHRAE Standard 241 compliant air purification reported significant outcomes over a 24-month observation period. Facilities recorded 28% lower HVAC energy consumption than code-minimum buildings while maintaining airborne pathogen levels below 80 CFU/m³ throughout various occupancy scenarios.

Validating Air Filter Function Excellence

Third-party certification remains essential for performance verification. Leading industrial filtration systems undergo testing per ISO 12500 standards for oil aerosol removal and pressure drop characteristics. Certification bodies including NSF International and Eurovent provide independent validation against stringent criteria such as EN1822 for HEPA filters and UL 900 for fire safety ratings.

Regular performance monitoring using calibrated laser particle counters and ISO 8573 testing protocols provides empirical evidence of filtration effectiveness. Facilities that implement continuous monitoring report 22% longer filter service intervals by eliminating unnecessary replacements while maintaining critical air quality standards. These verification methodologies ensure filtration systems consistently meet their engineered performance specifications throughout operational lifecycles.

(air filter function)

FAQS on air filter function

以下是根据核心关键词“air filter function”及其相关词创建的5组英文FAQs问答。每个FAQ组使用HTML富文本形式,问题以H3标签表示(如`Q: ...

`),答案以段落标签表示(如`A: ...

`)。问题和回答均控制在三句话内,确保简洁准确。Q: How does the air filter function work in an HVAC system?

A: The air filter traps dust, pollen, and airborne particles to purify air passing through the system. It improves indoor air quality by reducing pollutants and allergens for healthier breathing.

Q: What is the function of an air compressor air filter?

A: It protects the compressor by removing contaminants like oil and moisture from intake air. This ensures clean air supply to maintain performance and prevent damage to equipment.

Q: How does an air conditioner with air purifier function effectively?

A: It cools the air while its built-in filter system captures impurities. This dual-action provides both temperature control and purification for enhanced indoor comfort.

Q: What benefits does the air filter function offer in homes?

A: It reduces allergens such as pollen and pet dander, lowers energy costs by improving system efficiency, and prolongs device lifespan by preventing clogs.

Q: When should I maintain the air filter in an air conditioner or purifier?

A: Replace filters every 1-3 months to avoid performance loss. Regular maintenance ensures optimal air quality and prevents potential system malfunctions.

share

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.25,2025

-

CE Certification Metal Fine Mesh for Safety & Durability

NewsJul.24,2025

-

High-Efficiency Particle Filter for Superior Air Purification

NewsJul.23,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.22,2025

-

CE Certified 250 Micron Stain Steel Mesh - Durable & Safe

NewsJul.21,2025

-

CE Certified 250 Micron Stainless Steel Mesh - High Durability & CE Approved

NewsJul.21,2025