feb . 16, 2025 13:05 Back to list

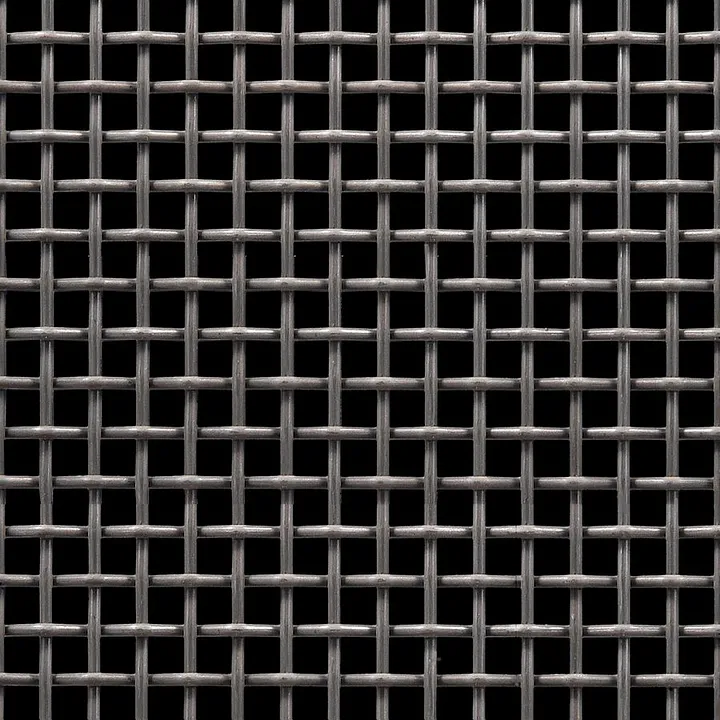

buy fine wire mesh

Purchasing fine wire mesh can be a crucial decision for industries ranging from industrial filtration to artisanal crafts. The process demands not only an understanding of your specific needs but also a comprehensive appreciation of the intricacies involved in wire mesh production and application. This article delves into the essential factors to consider when acquiring fine wire mesh, providing unique insights and in-depth expertise.

In addition to technical specifications, practical considerations like delivery times, storage, and handling form an integral part of the purchasing decision. Fine wire mesh is delicate, requiring careful handling to maintain integrity. Assessing suppliers' logistical capabilities and their understanding of these nuances contributes to smoother procurement and reliable service. It is essential for purchasers to evaluate the supplier's track record and customer feedback, fostering a relationship built on trust and reliability. Establishing a long-term partnership with a reputable supplier facilitates consistent quality and potentially offers avenues for customized solutions tailored to evolving needs. This approach underscores the significance of building trust through demonstrable performance and client satisfaction. Real-world experience enriches purchasing strategies with anecdotal insights and practical advice. Peer recommendations and case studies can illuminate challenges and solutions encountered by others in similar predicaments. Engaging in industry forums and trade shows can connect buyers with a community of experts, enhancing understanding and fostering collaborative problem-solving. Finally, investing in training and development for internal teams empowers organizations to make informed decisions. Understanding the complexities of fine wire mesh, from material science to advanced manufacturing techniques, elevates an organization's capability to navigate the market effectively. Knowledgeable teams can articulate precise needs and evaluate alternatives critically, ensuring optimal outcomes from commercial engagements. In summary, buying fine wire mesh involves a multi-faceted approach that balances technical specifications, material properties, compliance, and supplier reliability. By aligning practices with experience, expertise, authoritativeness, and trustworthiness, organizations can make sound investments that enhance operational efficiency and deliver long-term value.

In addition to technical specifications, practical considerations like delivery times, storage, and handling form an integral part of the purchasing decision. Fine wire mesh is delicate, requiring careful handling to maintain integrity. Assessing suppliers' logistical capabilities and their understanding of these nuances contributes to smoother procurement and reliable service. It is essential for purchasers to evaluate the supplier's track record and customer feedback, fostering a relationship built on trust and reliability. Establishing a long-term partnership with a reputable supplier facilitates consistent quality and potentially offers avenues for customized solutions tailored to evolving needs. This approach underscores the significance of building trust through demonstrable performance and client satisfaction. Real-world experience enriches purchasing strategies with anecdotal insights and practical advice. Peer recommendations and case studies can illuminate challenges and solutions encountered by others in similar predicaments. Engaging in industry forums and trade shows can connect buyers with a community of experts, enhancing understanding and fostering collaborative problem-solving. Finally, investing in training and development for internal teams empowers organizations to make informed decisions. Understanding the complexities of fine wire mesh, from material science to advanced manufacturing techniques, elevates an organization's capability to navigate the market effectively. Knowledgeable teams can articulate precise needs and evaluate alternatives critically, ensuring optimal outcomes from commercial engagements. In summary, buying fine wire mesh involves a multi-faceted approach that balances technical specifications, material properties, compliance, and supplier reliability. By aligning practices with experience, expertise, authoritativeness, and trustworthiness, organizations can make sound investments that enhance operational efficiency and deliver long-term value.

share

Next:

Latest news

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025

-

Premium Stainless Steel Mosquito Mesh - Durable, Rust-Resistant Protection for Windows & Doors

NewsJul.08,2025

-

Premium Stainless Steel Garden Mesh for Lasting Durability Best & High Quality Mesh Solutions

NewsJul.07,2025

-

Gold and White Blackout Curtains – Elegant Light Blocking & Insulation for Home

NewsJul.07,2025

-

Premium Spa Filter Cartridge for Clean Water Spa Pool Filters Cartridges for Jacuzzi Durable, high-efficiency spa filter cartridge for spas and jacuzzis. Improve water quality—order your pool filter cartridge now!

NewsJul.07,2025