sep . 18, 2024 12:48 Back to list

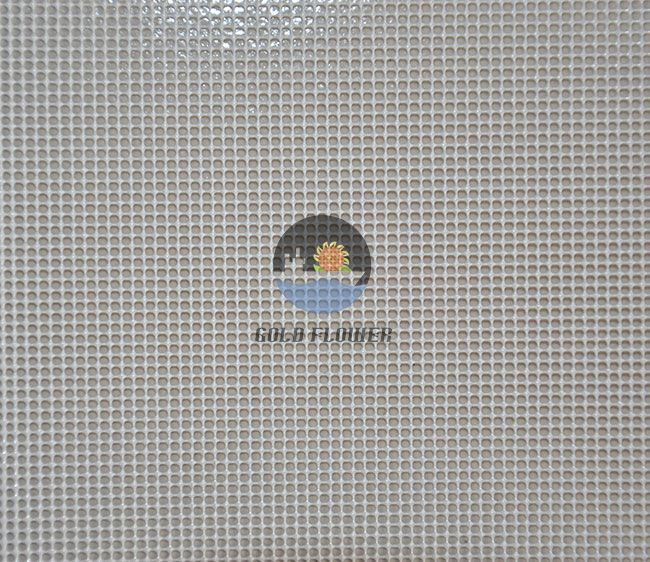

oem woven wire mesh cloth

The Versatility of OEM Woven Wire Mesh Cloth

In today's industrial landscape, the demand for specialized materials has given rise to innovative solutions tailored to specific applications. One such product that has gained significant popularity is OEM woven wire mesh cloth. This versatile material is essential in various sectors, including construction, automotive, filtration, and agriculture, due to its unique properties and customizable features.

What is OEM Woven Wire Mesh Cloth?

OEM, or Original Equipment Manufacturing, refers to the practice of producing parts or products that are used in another company's end product. In the case of woven wire mesh cloth, OEM suppliers create customized wire mesh solutions tailored to the precise specifications of their clients. The woven design allows for a higher level of customization, making it suitable for various applications, including screens, filters, and protective barriers.

The wire mesh is typically made from materials such as stainless steel, carbon steel, and other alloys, which provide durability, corrosion resistance, and longevity. The mesh can be woven in different patterns and with varying wire diameters, allowing for a wide range of aperture sizes and strengths.

Applications Across Industries

1. Construction and Architecture OEM woven wire mesh cloth is extensively used in construction, offering structural support in concrete applications and serving as reinforcement in walls and facades. Its ability to provide ventilation while maintaining strength makes it an ideal choice for modern architectural designs.

2. Filtration In industries such as food and beverage, pharmaceuticals, and water treatment, woven wire mesh cloth serves as essential filtration media. Its customizable aperture sizes allow for efficient separation of solids from liquids, ensuring product purity and compliance with health standards.

oem woven wire mesh cloth

3. Automotive Industry The automotive sector utilizes OEM woven wire mesh for applications such as air filters and protective screens. The material’s ability to withstand high temperatures and its lightweight nature make it an optimal choice for performance-driven vehicles.

4. Agricultural Uses In agriculture, woven wire mesh cloth is ideal for creating fencing and bird nets, providing protection for crops and livestock. Its sturdy design ensures durability against the elements, while its flexibility allows for various configurations to suit different needs.

Customization and Benefits

One of the key advantages of OEM woven wire mesh cloth is its customizability. Clients can specify wire diameter, mesh pattern, and aperture size, tailoring the product to their precise requirements. This level of personalization ensures that the final product meets specific performance and regulatory standards, thereby enhancing operational efficiency.

Furthermore, the durability and resistance to environmental factors make woven wire mesh cloth a cost-effective solution. Its long lifespan means fewer replacements, reducing overall expenses for businesses in the long run.

Conclusion

In summary, OEM woven wire mesh cloth stands out as a versatile material that meets the diverse needs of various industries. Its customizable nature, combined with durability and performance, makes it an invaluable asset in today’s market. As industries continue to evolve, the demand for quality woven wire mesh cloth will undoubtedly increase, driving further innovation in this essential material. Whether for construction, filtration, automotive, or agricultural applications, OEM woven wire mesh is a testament to the ongoing advancement of specialized manufacturing solutions.

share

-

CE Certified 250 Micron Stainless Steel Mesh Filter

NewsAug.04,2025

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025