okt . 21, 2024 04:09 Back to list

OEM Stainless Steel Mesh Screens for Various Applications and Industries

The Versatility and Benefits of OEM Mesh Screen Stainless Steel

In today’s industrial landscape, the demand for high-quality materials is paramount, particularly in applications requiring durability and corrosion resistance. One such material that has gained immense popularity is stainless steel mesh screens. These screens, when offered as Original Equipment Manufacturer (OEM) products, can significantly enhance various operational processes in multiple industries. This article explores the benefits, applications, and considerations of using OEM mesh screen stainless steel.

What is OEM Mesh Screen Stainless Steel?

OEM mesh screen stainless steel refers to specially manufactured screens designed to meet specific requirements set by original equipment manufacturers. These mesh screens are crafted from several grades of stainless steel, ensuring optimal performance in various conditions, including exposure to harsh environments. The mesh can differ in terms of aperture size, thickness, and weave pattern, depending on the ultimate application.

Key Benefits

1. Corrosion Resistance Stainless steel is known for its impressive resistance to rust and corrosion, making it an ideal choice for applications in moist or aggressive environments. Whether in chemical processing plants, marine settings, or food production, OEM mesh screen stainless steel can withstand harsh conditions without deteriorating.

2. Strength and Durability Stainless steel mesh screens are robust and can endure significant mechanical stress. Their strength means that they can be employed in various applications, including filtration, sieving, and structural support. OEM specifications ensure that the material meets required standards, thus enhancing its reliability.

3. Versatility The customizability of OEM mesh makes it suitable for a wide range of applications across diverse sectors. From mining operations and water treatment to pharmaceuticals and aerospace, stainless steel mesh screens can be tailored to meet the specific needs of the industry, whether it involves filtration or reinforcement.

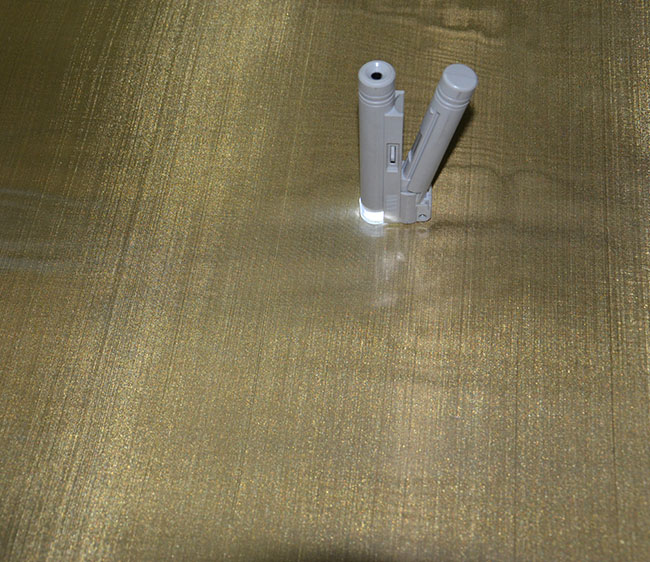

oem mesh screen stainless steel

4. Ease of Maintenance Stainless steel is easy to clean, which is crucial for industries such as food and pharmaceuticals, where sanitation is paramount. The smooth surface of stainless steel mesh screens minimizes the accumulation of bacteria and other contaminants, facilitating compliance with health regulations.

5. Cost-Effectiveness Although the initial investment in high-quality OEM mesh screen stainless steel might be higher than alternative materials, the long-term benefits outweigh this cost. Their durability and low maintenance requirements reduce replacement frequency and ongoing operational costs.

Applications

The applications of OEM mesh screen stainless steel are vast and varied. In the food processing industry, these meshes are used for slicing, filtering, and sieving various products, ensuring consistency and safety. The oil and gas sector employs stainless steel mesh in filtration systems to remove impurities and protect equipment. The pharmaceutical industry utilizes these screens for drug filtration and hygiene compliance.

Furthermore, in construction and architecture, stainless steel mesh is often used in facades and cladding systems, combining aesthetic appeal with functional durability. The automotive industry integrates these mesh screens in air and coolant filtration systems, enhancing the efficiency and longevity of the vehicles.

Considerations

When selecting OEM mesh screen stainless steel, it is essential to consider factors such as the grade of stainless steel, mesh size, and the specific application requirements. Engaging with a reputable manufacturer can ensure that the final product not only meets but exceeds the necessary industry standards.

In conclusion, OEM mesh screen stainless steel presents an impressive combination of strength, versatility, and resistance, making it an excellent choice for various industrial applications. By considering the unique benefits and applications, businesses can harness this material’s full potential, ensuring operational efficiency and long-lasting performance. As industries continue to evolve, the use of such advanced materials will likely play a critical role in driving innovation and enhancing productivity.

share

-

High-Quality Screen Stone for Modern Stone Screen Walls Elegant Facade Solutions

NewsJun.10,2025

-

High Quality Wire Filter – Cheap Stainless Steel Filter Wire Mesh Cloth & Wire Mesh Filter Solutions

NewsJun.10,2025

-

5 Micron Water Filter Cartridge - Premium Sediment Filtration, Universal Fit

NewsJun.10,2025

-

High Quality CE-Certified Gabion Boxes with OEM Options

NewsJun.10,2025

-

20x20x2 Air Filter High-Efficiency Dust Filtration for Clean Air

NewsJun.10,2025

-

Decorative Metal Mesh for Radiator Covers Custom Durable Mesh Panels

NewsJun.10,2025