mar . 10, 2025 10:07 Tillbaka till listan

The Versatility of Sintered Wire Mesh: An In-Depth Guide

Sintered wire mesh has become an essential material for various filtration, separation, and industrial applications due to its strength, durability, and versatility. Whether you are dealing with air, liquid, or solid filtration, sintered wire mesh solutions provide an efficient and reliable option for your needs. This article explores the different types of sintered wire mesh and their benefits, including sintered wire mesh, sintered wire cloth, sintered metal mesh, and 5 layer sintered wire mesh, and highlights how these products can enhance your filtration systems.

Sintered Wire Mesh: Strength and Durability for Filtration Systems

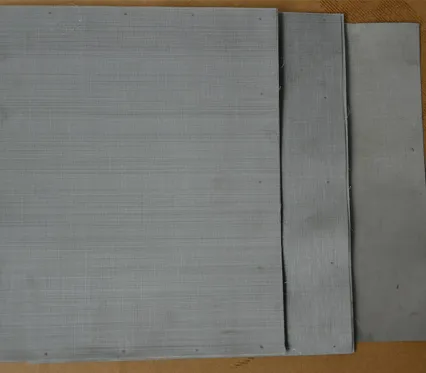

Sintered wire mesh is a highly effective material used in a wide range of filtration applications. Made from woven metal wires that are bonded together through a sintering process, sintered wire mesh provides exceptional mechanical strength, high porosity, and excellent resistance to heat, pressure, and chemical corrosion. These properties make sintered wire mesh ideal for applications that require stable, long-lasting performance in harsh conditions.

The sintering process enhances the mesh’s integrity, preventing the wires from unraveling or distorting during filtration operations. With sintered wire mesh, manufacturers and engineers can achieve precise filtration results, which are crucial in industries such as oil and gas, pharmaceuticals, food processing, and water treatment. Furthermore, sintered wire mesh is available in various mesh sizes and pore structures, allowing for tailored solutions that meet specific filtration requirements.

Due to its robust nature, sintered wire mesh is highly durable, ensuring that it can withstand high pressures and temperatures, making it the go-to choice for industrial filtration systems. The material also offers excellent resistance to mechanical stresses, making it perfect for applications that require a filter that can perform over extended periods without deterioration.

Sintered Wire Cloth: Versatile Applications in Different Industries

Another valuable product in the world of filtration is sintered wire cloth, which shares many similarities with sintered wire mesh but offers additional flexibility in its applications. Sintered wire cloth typically consists of multiple layers of mesh that are fused together through a sintering process, providing even greater strength and uniformity. The combination of layers in sintered wire cloth enhances its performance, enabling it to handle even the most demanding filtration tasks.

One of the key advantages of sintered wire cloth is its versatility. It can be used for both fine and coarse filtration, making it suitable for a wide variety of industries. In the food and beverage sector, for example, sintered wire cloth is often used to filter out impurities in oils, liquids, and powders. Similarly, in the pharmaceutical industry, it ensures that active ingredients remain pure by efficiently filtering contaminants from raw materials or end products.

In addition to filtration, sintered wire cloth is also employed in applications like catalyst support, separation, and even in pressure vessels. Its robust construction ensures that it can withstand significant mechanical forces, such as high-pressure differential across the mesh during filtration processes. The durability and performance of sintered wire cloth make it an excellent choice for industries requiring consistent and reliable filtration systems.

Sintered Metal Mesh: Advanced Filtration with High Performance

When it comes to advanced filtration solutions, sintered metal mesh is a popular choice for industries that need high-performance materials. Sintered metal mesh combines the benefits of both sintering and metal, offering exceptional resistance to wear, corrosion, and high temperatures. Made from stainless steel or other metal alloys, sintered metal mesh provides a stronger and more stable filtration material compared to traditional woven metal meshes.

Due to its superior mechanical properties, sintered metal mesh is frequently used in applications that require high-temperature filtration, such as in the aerospace, automotive, and chemical industries. The material’s ability to handle extreme conditions while maintaining its structural integrity ensures that sintered metal mesh is a long-lasting, cost-effective solution for complex filtration tasks.

Moreover, sintered metal mesh is known for its ability to maintain consistent pore sizes throughout its surface, ensuring high filtration efficiency and uniformity. Whether used in liquid filtration, gas filtration, or as a part of an industrial filtration system, sintered metal mesh is designed to provide optimal performance and high-quality filtration over long periods, reducing the need for frequent replacements and maintenance.

5 Layer Sintered Wire Mesh: Precision Filtration for High-Flow Applications

For applications that require even higher filtration precision, 5 layer sintered wire mesh is an advanced solution. Comprising five layers of wire mesh fused together, 5 layer sintered wire mesh offers enhanced filtration capabilities due to the varying mesh sizes of each layer. The different layers work in conjunction to trap particles of different sizes, providing a highly efficient filtration system.

One of the key benefits of 5 layer sintered wire mesh is its ability to handle high-flow filtration without compromising on filtration efficiency. The multi-layer construction ensures that particles are captured at various stages, which helps prevent clogging and ensures continuous performance in high-flow systems. This makes 5 layer sintered wire mesh ideal for applications that require both fine and coarse filtration, such as water treatment, oil filtration, and industrial processes.

Additionally, 5 layer sintered wire mesh is designed to maintain its structural integrity even under high-pressure conditions. This makes it particularly useful for industries where filtration systems are exposed to extreme operational pressures and temperatures. The high flow capacity and filtration precision make 5 layer sintered wire mesh an excellent choice for industries requiring consistent, high-efficiency filtration systems that can handle large volumes of fluid or gas.

Choosing the Right Sintered Mesh for Your Needs

Selecting the right sintered mesh for your filtration requirements depends on several factors, including the type of fluid or gas being filtered, the size and type of contaminants, and the specific operating conditions. Whether you are considering sintered wire mesh, sintered wire cloth, sintered metal mesh, or 5 layer sintered wire mesh, each option offers distinct advantages.

For applications that require high strength, durability, and heat resistance, sintered metal mesh och 5 layer sintered wire mesh are ideal choices. These products are perfect for industries like oil and gas, automotive, and pharmaceuticals, where consistent filtration under extreme conditions is crucial. On the other hand, if you require a versatile and cost-effective solution, sintered wire cloth och sintered wire mesh may be more suitable, offering effective filtration for a wide range of applications.

When selecting a sintered mesh product, it’s important to work closely with a supplier or manufacturer who can help you assess your filtration needs and recommend the best solution based on your specific requirements. A reliable manufacturer will guide you through the options, ensuring that you get the most suitable product for your application.

Sintered mesh products, including sintered wire mesh, sintered wire cloth, sintered metal mesh, and 5 layer sintered wire mesh, provide essential filtration solutions for a wide range of industries. These materials offer superior strength, high filtration efficiency, and the ability to withstand harsh conditions, making them an excellent choice for demanding filtration applications.

By choosing the right sintered mesh product, you can ensure that your filtration systems perform at their best, whether you are filtering liquids, gases, or solid particles. The robust construction and superior performance of sintered mesh products make them an invaluable asset to industries that require precise filtration and long-term reliability. Investing in sintered mesh ensures you get the highest quality filtration solutions, providing clean, safe materials for industrial processes, environmental protection, and consumer use.

In conclusion, whether you need sintered wire mesh, sintered wire cloth, sintered metal mesh, or 5 layer sintered wire mesh, these products offer exceptional value for filtration systems in various sectors. By understanding the advantages of each type of sintered mesh, you can select the best option to meet your needs and achieve superior filtration performance.

This article covers the benefits and applications of sintered wire mesh, sintered wire cloth, sintered metal mesh, and 5 layer sintered wire mesh, providing a comprehensive guide for those looking to choose the best filtration solutions for their industries.

dela med sig

-

What Are the Key Applications and Benefits of Chicken Wire Gabion and Related Retaining Solutions?

NyheterJul.18,2025

-

What Are the Key Advantages and Applications of PVC Coated Gabion Wire Mesh and Related Solutions?

NyheterJul.18,2025

-

Welded Gabion Mesh Solutions: Strength and Versatility in Construction

NyheterJul.18,2025

-

Essential Solutions for Slope Stability: A Focus on Protective Nets

NyheterJul.18,2025

-

Durable Solutions for Erosion Control and Construction: Galvanised Gabion Systems

NyheterJul.18,2025

-

Constructing Functional Structures: The Art of Making Gabions

NyheterJul.18,2025