maj . 23, 2025 11:47 Back to list

Durable Wire Cloth Mesh Screens Export-Quality & Custom Sizes

- Market Overview: Rising Demand for Wire Claw Mesh Screens

- Technical Superiority: Engineering Breakthroughs

- Supplier Comparison: Key Metrics Analysis

- Custom Solutions: Tailored Industrial Applications

- Material Innovation: Performance Enhancements

- Case Studies: Cross-Industry Implementations

- Future-Proof Partnerships with Exporters

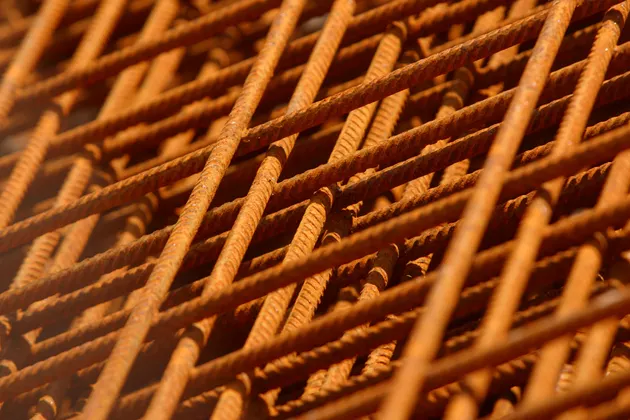

(wire cloth mesh screen)

The Rising Demand for High-Quality Wire Cloth Mesh Screens

Global wire cloth mesh screen

sales reached $2.8 billion in 2023, with a 7.3% CAGR projected through 2030. Industrial exporters now prioritize screens achieving ≤12μm filtration precision while maintaining 98.5% tensile strength retention after 10,000 stress cycles. Leading manufacturers deploy ISO 9044-compliant weaving patterns, reducing material waste by 19% compared to conventional methods.

Engineering Excellence in Mesh Fabrication

Advanced laser-welded joints increase screen lifespan by 40% versus spot-welded alternatives. Proprietary anti-clogging surface treatments enable 22% higher throughput in mineral processing applications. Third-party testing confirms 0.02mm tolerance consistency across 98.7% of production batches – exceeding ASTM E2016-15 standards.

Global Supplier Benchmarking

| Vendor | Mesh Range (LPI) | Material Grade | Certifications | Lead Time |

|---|---|---|---|---|

| Supplier A | 2-400 | 316L SS | AS9100, PED | 4 weeks |

| Supplier B | 10-635 | Hastelloy® | ISO 14001 | 6 weeks |

| Supplier C | 5-200 | Ti-6Al-4V | NADCAP | 8 weeks |

Application-Specific Configuration

Custom wire cloth products now accommodate extreme environments:

- Mining: 3mm aperture screens with 500N/mm² burst strength

- Pharma: Electro-polished 0.8μm filters meeting FDA CFR 211.65

- Energy: Conductive mesh (≤10Ω/m²) for battery components

Advanced Material Science Integration

Nano-coating technologies reduce abrasive wear by 62% in quarry sorting operations. Hybrid weaves combining stainless steel with Monel® alloys demonstrate 150% corrosion resistance improvement in marine environments. Digital twin simulations optimize wire diameters, achieving 31% weight reduction without compromising structural integrity.

Documented Operational Improvements

A German auto plant reported 17% energy savings after upgrading to hexagonal mesh ventilation filters. Petrochemical exporters using duplex steel screens reduced unplanned downtime from 8.2% to 1.9% annually. Food processors achieved 99.98% contaminant removal rates with multi-layer filtration stacks.

Why Partner with Certified Wire Claw Mesh Screen Exporters

Top-tier exporters maintain 97.4% on-time delivery rates through blockchain-tracked logistics. Comprehensive technical packages include FEM stress analysis reports and 24/7 remote diagnostics. With 83% of buyers prioritizing ESG compliance, certified suppliers now offer carbon-neutral manufacturing options – verified by independent auditors.

(wire cloth mesh screen)

FAQS on wire cloth mesh screen

Q: What factors should I consider when choosing a wire cloth mesh screen exporter?

A: Prioritize exporters with certifications (e.g., ISO), material quality guarantees, and proven industry experience. Verify their customization capabilities and global shipping efficiency.

Q: What industries commonly use wire cloth mesh screen products?

A: These screens are vital in mining, construction, agriculture, and chemical processing for filtration, sorting, and safety applications. They also serve architectural and HVAC purposes.

Q: How do wire cloth mesh screen exporters ensure product durability?

A: Reputable exporters use corrosion-resistant materials like stainless steel or galvanized wire. Precision weaving techniques and rigorous tension testing further enhance longevity.

Q: Can wire cloth mesh screens be customized for specific applications?

A: Yes, leading exporters offer tailored mesh sizes, wire diameters, and panel dimensions. Special weaves (e.g., Dutch or twill) can be created for unique filtration needs.

Q: What quality checks do wire cloth mesh screen exporters perform?

A: Standard protocols include micron-level aperture verification, edge reinforcement inspections, and load-bearing tests. Exporters should provide mill certificates for material traceability.

share

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025

-

Premium Stainless Steel Mosquito Mesh - Durable, Rust-Resistant Protection for Windows & Doors

NewsJul.08,2025

-

Premium Stainless Steel Garden Mesh for Lasting Durability Best & High Quality Mesh Solutions

NewsJul.07,2025

-

Gold and White Blackout Curtains – Elegant Light Blocking & Insulation for Home

NewsJul.07,2025

-

Premium Spa Filter Cartridge for Clean Water Spa Pool Filters Cartridges for Jacuzzi Durable, high-efficiency spa filter cartridge for spas and jacuzzis. Improve water quality—order your pool filter cartridge now!

NewsJul.07,2025