jan . 06, 2025 18:51 Back to list

Stainless Steel Wire Cloth

Navigating the world of wire cloth products can be daunting, yet it is a crucial component for various industrial applications. With over two decades of experience in the industry, I've seen how impactful choosing the right wire cloth can be for ensuring efficiency and longevity in applications ranging from filtration systems to architectural design.

Wire cloth, also known as woven wire mesh, exemplifies the fine craftsmanship that goes into creating products essential for numerous fields including aerospace, agriculture, and pharmaceuticals. This product offers unparalleled versatility due to its customizable nature; it can be crafted using different materials like stainless steel, brass, copper, and more, each bringing unique properties to cater to specific needs.

From a professional standpoint, selecting the appropriate wire cloth involves understanding the exact requirements of your project. For instance, consider the environment in which the wire cloth will be employed. A corrosive environment will necessitate the use of stainless steel mesh for its inherent resistance to rust and corrosion, contributing to prolonged service life. I recall a case where a pharmaceutical company significantly reduced their maintenance costs simply by switching to a stainless steel wire cloth, transitioning from a less resistant metal that frequently necessitated replacements.

The expertise I bring goes beyond material choice. Mesh size, wire diameter, and weave pattern are all pivotal in achieving optimal function. For instance, in filtration applications, a tighter mesh with a plain weave ensures effective separation of particles. This specificity not only enhances performance but also boosts energy efficiency, as the well-chosen wire cloth reduces back pressure in filtration.

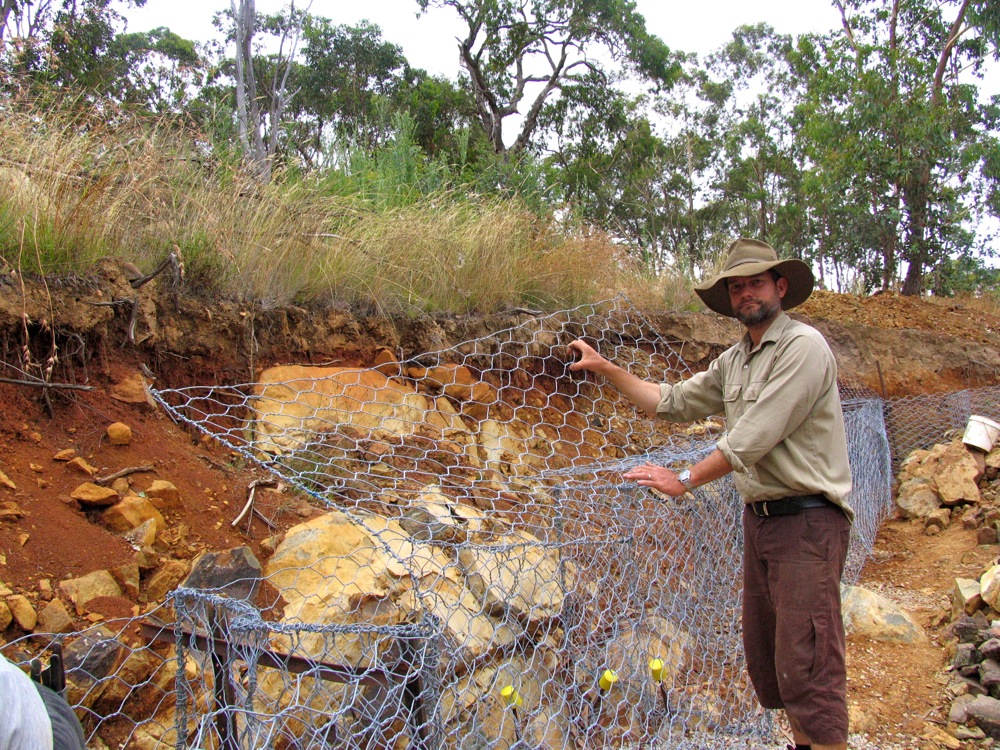

wire cloth

Authoritativeness in the realm of wire cloth also means staying informed about technological advancements. Innovations such as 3D weaving technology allow for even more precise configurations, enhancing capabilities in highly specialized sectors. Establishing strong relationships with quality manufacturers gives you access to these technological advancements, ensuring the wire cloth's specifications perfectly align with project demands.

Trustworthiness stems from transparency and reliability. Providing clients with detailed technical data sheets, along with a clear history of material sourcing, builds trust. In my years of consultancy, I have found that a comprehensive approach where clients are educated about the lifecycle and maintenance of wire cloth led to more successful outcomes. For example, a detailed maintenance guide helped a food processing plant adhere to hygiene standards, avoiding costly shutdowns.

When deployed correctly, wire cloth products deliver exceptional performance across various applications. It’s a testament to their importance that industries continually seek out this material for high-demand tasks. To remain at the forefront, firms must prioritize acquiring certified, quality materials and delve deeply into research and consultation to ensure every specification aligns with industry regulations and operational needs.

Choosing the correct wire cloth can redefine project success. With the right knowledge and expert guidance, you're empowered to select a solution that not only meets but exceeds expectations, ensuring robustness and efficiency for years to come.

share

-

Precision CE Certified 250 Micron Stainless Steel Mesh

NewsAug.13,2025

-

CE Certified Metal Fine Mesh & Screen Fabric | Top Quality

NewsAug.12,2025

-

Premium CE Certified 250 Micron Stainless Steel Mesh

NewsAug.11,2025

-

CE Certified Stainless Steel Wire Mesh for Screen Printing

NewsAug.10,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.09,2025

-

Decorative Brass Mesh: Elevate Interiors with Timeless Elegance

NewsAug.08,2025