Eyl . 04, 2024 05:35 Back to list

high quality forming wire mesh

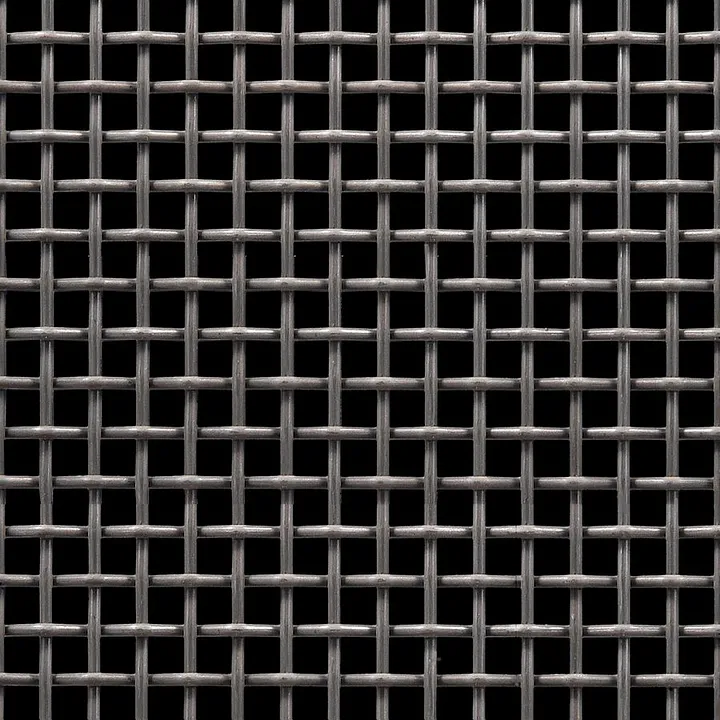

High-Quality Forming Wire Mesh An Essential Component in Various Industries

Wire mesh is a versatile product that finds extensive use in diverse applications ranging from construction to agriculture. Among its various forms, high-quality forming wire mesh stands out due to its superior strength, durability, and adaptability. This article explores the characteristics, manufacturing processes, and applications of high-quality forming wire mesh.

Characteristics of High-Quality Forming Wire Mesh

High-quality forming wire mesh is primarily recognized for its exceptional tensile strength and corrosion resistance. These attributes are pivotal, especially in environments that demand resilience against physical stress and chemical exposure. The wire mesh is typically made from stainless steel or galvanized steel, ensuring longevity and stability even in harsh conditions. Additionally, the mesh exhibits excellent flexibility, allowing it to conform to various shapes and forms without compromising its structural integrity.

Another critical characteristic is the precision of its openings. High-quality forming wire mesh is manufactured with meticulous attention to detail, ensuring uniformity in the size and spacing of the mesh openings. This precision is essential for applications that require specific filtration capabilities or structural support.

Manufacturing Processes

The manufacturing of high-quality forming wire mesh involves several sophisticated processes. Initially, high-grade raw materials are selected to enhance the mesh's performance characteristics. The wire is then drawn to the desired gauge and cut into specified lengths. The next step involves weaving or welding the wires together to form the mesh, employing techniques that maximize strength while minimizing weight.

high quality forming wire mesh

Advanced technologies are often integrated into the manufacturing process, such as automated weaving machines and computer-controlled welding systems. These technologies not only improve production efficiency but also ensure superior quality control. The final stage typically involves surface treatment, which may include galvanization or electro-polishing to enhance corrosion resistance and aesthetic appeal.

Applications of High-Quality Forming Wire Mesh

High-quality forming wire mesh is utilized in numerous industries, underscoring its versatility. In the construction industry, it serves as reinforcement for concrete structures, providing additional strength and stability. The mesh is also used in the creation of partitions and screens, offering safety and security in various environments.

In the agricultural sector, forming wire mesh plays a crucial role in fencing and cage construction. It protects crops from pests and animals while allowing for adequate ventilation and sunlight. Furthermore, the mesh is employed in garden projects, where it can support climbing plants or serve as a trellis.

Another important application is in the automotive and aerospace industries, where forming wire mesh is used in filtration systems. Its precise openings ensure that only desired particles pass through, which is essential for maintaining the functionality and efficiency of engines and machinery. Additionally, the mesh is used for soundproofing and thermal insulation in these high-tech environments.

Conclusion

In summary, high-quality forming wire mesh is an essential material that enriches various industries with its remarkable attributes and diverse applications. Its strength, durability, and adaptability make it suitable for settings that demand reliability and efficiency. As technology advances, the production methods and applications of forming wire mesh are likely to evolve, further enhancing its significance in modern industries. Whether in construction, agriculture, or manufacturing, high-quality forming wire mesh continues to be a crucial component that supports innovation and progress.

share

-

CE Certified Woven Wire Mesh Filters | Premium Filtration Solutions

NewsAug.19,2025

-

High-Performance Particle Filters: Optimal Mediums & Applications

NewsAug.18,2025

-

Competitive Screen Mesh Price | 1/4", 1/8", 1/2" Wire Mesh Screens

NewsAug.17,2025

-

CE Certified 250 Micron SS Mesh: Precision & Durability

NewsAug.15,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.14,2025

-

Precision CE Certified 250 Micron Stainless Steel Mesh

NewsAug.13,2025