Ara . 11, 2024 09:14 Back to list

Durable and Efficient Wire Mesh Filter Cloth for Optimal Filtration Solutions

The Importance of High-Quality Wire Mesh Filter Cloth

In industries ranging from food processing to pharmaceuticals, the necessity for high-quality filtration systems is unquestionable. One essential component in these systems is the wire mesh filter cloth, which plays a pivotal role in ensuring product purity, operational efficiency, and overall safety. This article explores the significance of high-quality wire mesh filter cloth and its applications in various sectors.

Understanding Wire Mesh Filter Cloth

Wire mesh filter cloth is a type of filtering medium made from woven or welded wire strands that create an open structure. The mesh is designed to retain solid particles while allowing liquids or gases to pass through. The quality of the wire mesh can significantly affect its filtration performance, durability, and maintenance requirements.

Key Characteristics of High-Quality Filter Cloth

1. Material Composition High-quality wire mesh is typically made from stainless steel or other corrosion-resistant materials. This ensures longevity, especially in demanding environments where exposure to chemicals or high temperatures is common.

2. Mesh Opening Size The size of the openings in the mesh is critical to its filtering capability. High-quality wire mesh filter cloth offers precise opening sizes tailored to specific filtration needs, ensuring maximum efficiency in capturing contaminants.

3. Weave Design The weave pattern plays a crucial role in the strength and flexibility of the cloth. Durable weaves can withstand physical stress and prevent material failure, a common problem in lower-quality products.

4. Surface Finish A smooth surface finish can enhance the cloth's resistance to clogging and make it easier to clean. High-quality filter cloth often undergoes additional finishing processes to achieve the best surface characteristics.

Applications Across Industries

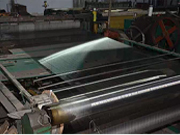

high quality wire mesh filter cloth

High-quality wire mesh filter cloth is versatile and finds application in various sectors

- Food and Beverage In the food industry, filtration is essential for maintaining product quality and safety. Wire mesh filter cloth is commonly used in processes such as brewing, juice production, and dairy processing to ensure that impurities are removed while preserving taste and flavor.

- Industrial Filtration Many manufacturing processes require stringent filtration to protect machinery and ensure product quality. High-quality wire mesh filter cloth is employed in water treatment plants, paint production, and chemical processing.

- Pharmaceuticals The pharmaceutical industry demands the highest purity standards. Wire mesh filter cloth is used in the filtration of active ingredients and final products, ensuring that no contaminants compromise the efficacy of medications.

- Paint and Coatings In the paint industry, wire mesh filter cloth helps remove particles from paint formulations, ensuring a smooth, high-quality finish in the final product.

Advantages of Using High-Quality Filter Cloth

Investing in high-quality wire mesh filter cloth offers numerous benefits. First and foremost, it leads to better filtration results, meaning higher-quality end products. Additionally, durable materials can reduce replacement frequency, ultimately saving costs over time. Moreover, effective filtration minimizes downtime and maintenance, enhancing overall productivity.

Conclusion

In conclusion, high-quality wire mesh filter cloth is an indispensable component in various industries that require efficient filtration solutions. By ensuring product purity and operational reliability, it helps businesses maintain high standards and customer satisfaction. As industries continue to evolve, the demand for advanced filtration technologies will only increase, making the role of high-quality wire mesh filter cloth more critical than ever. Investing in top-notch filter cloth is not merely a choice; it is a necessity for those committed to quality and excellence in their operations.

share

-

CE Certified 250 Micron Stainless Steel Mesh Filter

NewsAug.04,2025

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025