Kas . 01, 2024 02:31 Back to list

High-Quality Fine Mesh OEM Purchasing Solutions for Your Needs

Exploring the Benefits of OEM Fine Mesh Products A Comprehensive Guide

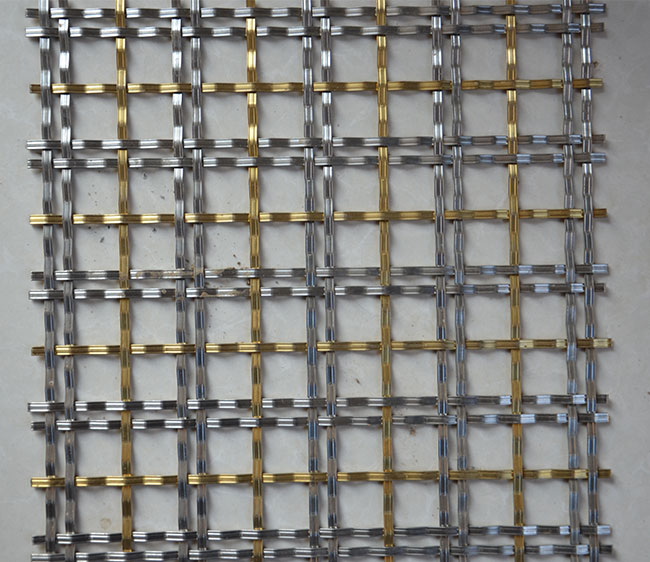

In today's fast-paced industrial landscape, the demand for high-quality products has never been greater. One such product that has gained significant attention is fine mesh, especially when it comes to Original Equipment Manufacturer (OEM) solutions. Fine mesh refers to a type of screen or filter made from woven materials, characterized by its small openings that allow for the filtration or separation of fine particles from liquids or gases. This article will explore the advantages of OEM fine mesh products, their applications, and the factors to consider when purchasing them.

Advantages of OEM Fine Mesh Products

1. Customization One of the primary benefits of opting for OEM fine mesh products is the level of customization available. OEM manufacturers can tailor their fine mesh solutions to meet specific industry requirements, ensuring that the product aligns perfectly with the unique needs of their clients. This includes variations in size, material, and mesh density.

2. Quality Assurance When purchasing directly from OEMs, companies can benefit from strict quality control processes. These manufacturers typically adhere to international standards, ensuring that their products are reliable and durable. As businesses strive for excellence, the assurance of quality is critical in maintaining their reputation in the market.

3. Cost-Effectiveness Although the initial investment for OEM products may seem higher than off-the-shelf alternatives, the long-term value often outweighs the costs. Fine mesh products from OEMs are designed to last longer and perform better, resulting in lower maintenance and replacement costs. Additionally, businesses can save on operational expenses due to increased efficiency.

4. Technical Support and Expertise When engaging with an OEM, businesses often gain access to a wealth of technical knowledge and support. This can be invaluable during the design and implementation phases, ensuring that the fine mesh products are integrated seamlessly into existing systems or processes.

Applications of OEM Fine Mesh Products

Fine mesh products find applications in a variety of industries, including

oem buy fine mesh

- Food and Beverage Used for sieving, filtration, and separation processes to ensure product purity and quality. - Pharmaceuticals Critical in the manufacturing of drugs, where the elimination of contaminants is essential. - Chemical Processing Employed for separating and filtering chemicals to ensure safe and efficient production. - Water Treatment Used in filtration systems to remove fine particles from water, contributing to clean and safe drinking water.

Factors to Consider When Buying OEM Fine Mesh

When looking to purchase OEM fine mesh products, there are several factors to keep in mind

1. Material Selection Different materials offer varying levels of strength, durability, and chemical resistance. Choose a material that aligns with your specific application requirements.

2. Mesh Size and Density Determine the appropriate mesh size and density based on the particles you wish to filter or separate. This is crucial for achieving optimal performance.

3. Manufacturer Reputation Research potential OEMs to ensure they have a solid reputation in the industry. Reviews and case studies can provide insights into their reliability and quality of service.

4. After-Sales Support Consider the level of after-sales support offered by the manufacturer. Reliable technical support and warranty options can enhance your overall purchasing experience.

In conclusion, OEM fine mesh products offer numerous benefits, including customization, quality assurance, and cost-effectiveness. As businesses continue to seek solutions that enhance operational efficiency and product quality, investing in fine mesh from reputable OEMs is a strategic choice. By carefully considering application requirements and manufacturer credibility, companies can secure the finest mesh solutions for their needs.

share

-

ODM Brass Wire Mesh Screens Custom Sizes & Antique Finishes

NewsMay.16,2025

-

China Netting Fence Wire - Durable & Fox Proof Wire Mesh Solutions

NewsMay.16,2025

-

Electrostatic Air Filters Washable, High-Efficiency HVAC & AC Solutions

NewsMay.16,2025

-

Metal Fly Curtains Durable Insect Barrier & Ventilation Solution

NewsMay.15,2025

-

ODM Steel Crimped Mesh High-Strength & Customizable Solutions

NewsMay.15,2025

-

Wire Mesh Filter Elements Durable & Affordable Filtration Solutions

NewsMay.14,2025